Flexible clamp for passenger car pedal skeleton welding

A flexible fixture and skeleton technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to ensure rigid positioning, achieve positioning accuracy and clamping functions, and realize adjustment and precise adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

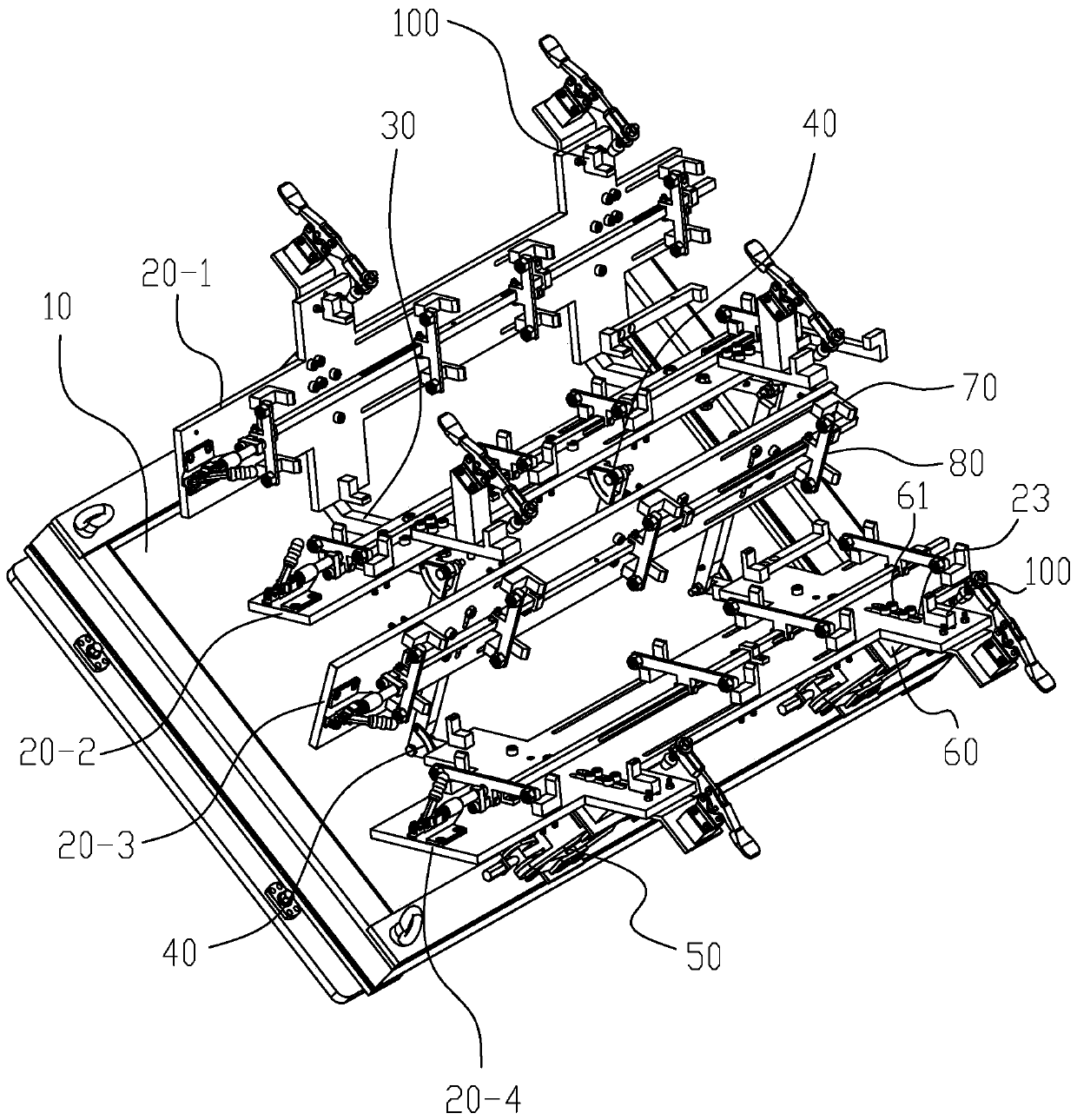

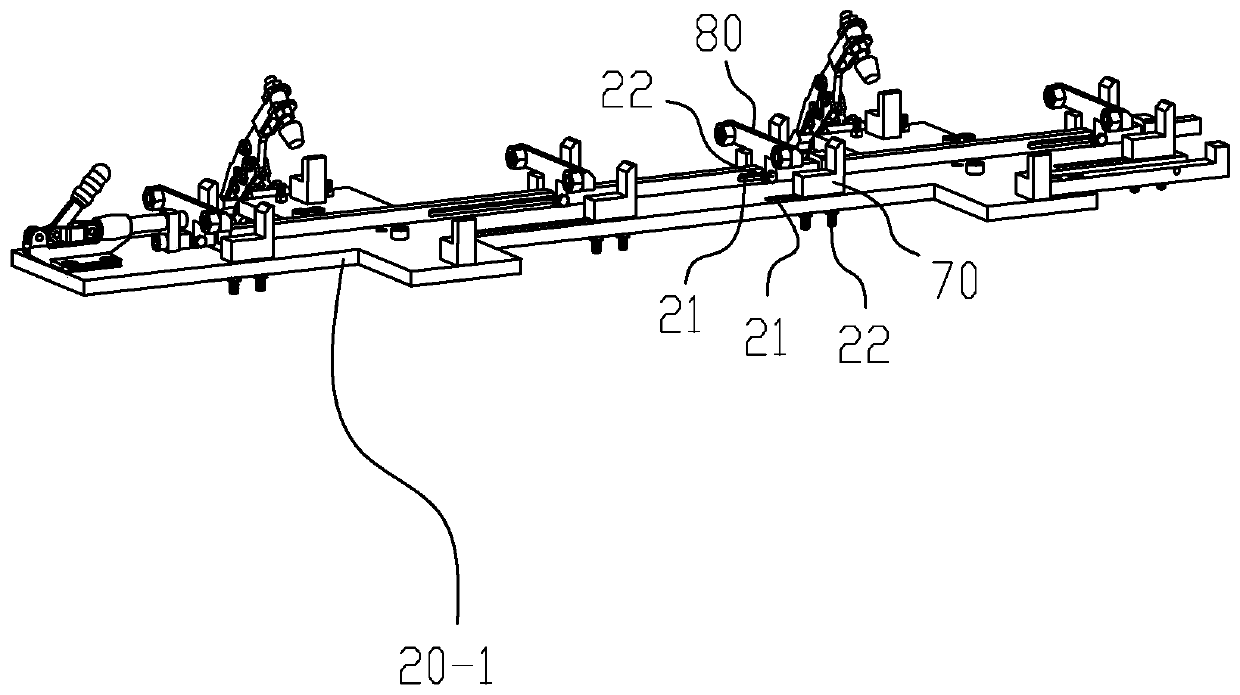

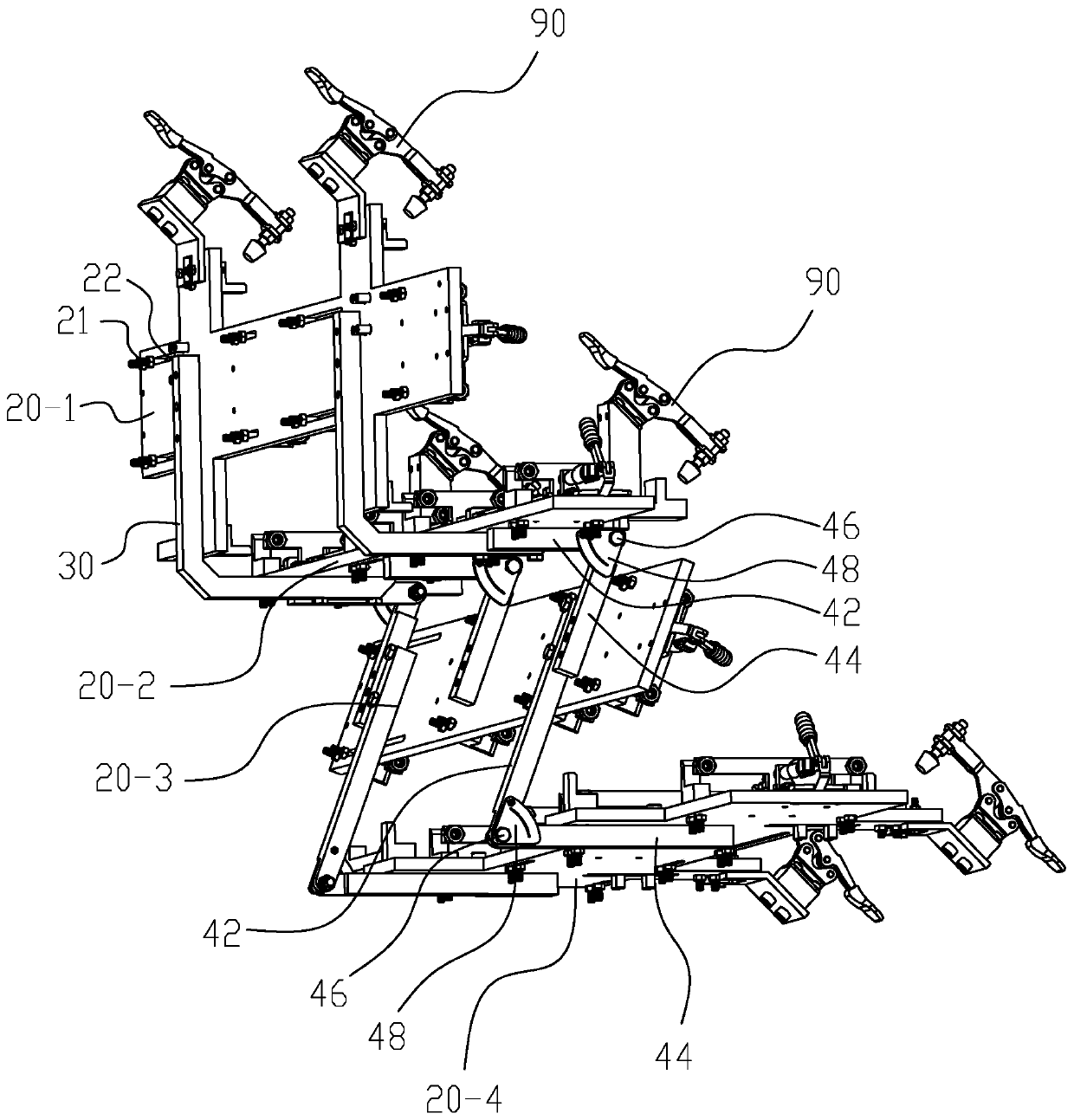

[0025] figure 1 Among them, the left-right direction of the base 10 is the horizontal direction, and the front-rear direction of the base 10 is the vertical direction. The limiting plate extends along the front and back direction of the base 10 , and in the plane where the limiting plate is located, the length direction of the limiting plate is defined as longitudinal direction, and the width direction of the limiting plate is defined as transverse direction.

[0026] Please refer to Figure 1 to Figure 4 , a flexible fixture for welding the pedal frame of a passenger car, including a base 10 and four limiting plates longitudinally arranged above the base, the four limiting plates are arranged in a W shape from left to right at intervals and defined as limiting plates in order 20-1, limit plate two 20-2, limit plate three 20-3, limit plate four 20-4. The left side of the top of the base 10 is provided with an L-shaped bracket 30 , and the included angle of the bracket 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com