Universal type transportation table supporting arm mechanism for engine cover

A kind of engine cover, general-purpose technology, applied in the direction of transportation and packaging, assembly machines, machine containers, etc., can solve the problems of poor versatility, inconvenient access to the limit mechanism, and non-adjustable limit slots, etc., to achieve convenient Pick and place, avoid excessive flipping, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

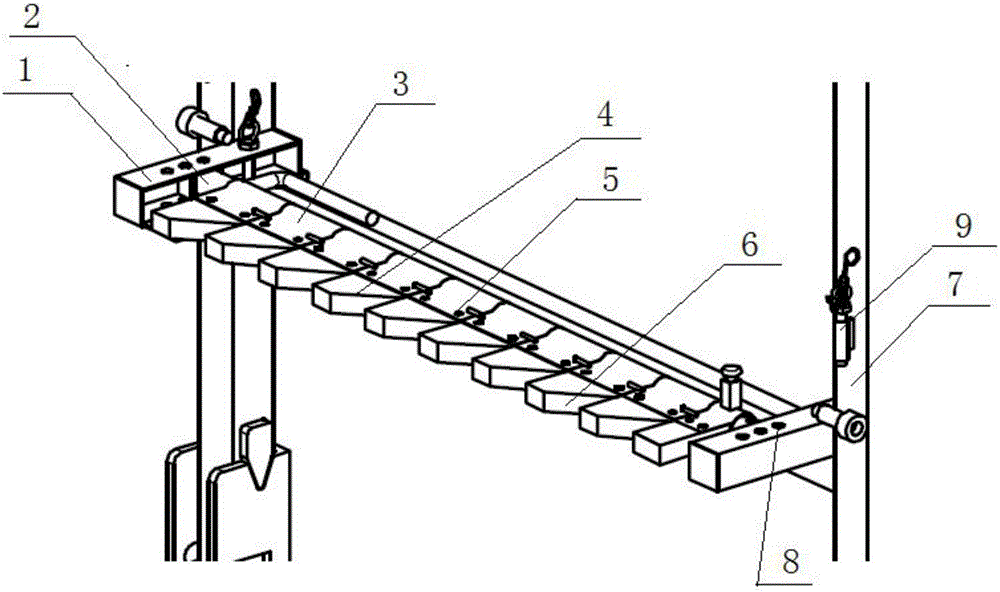

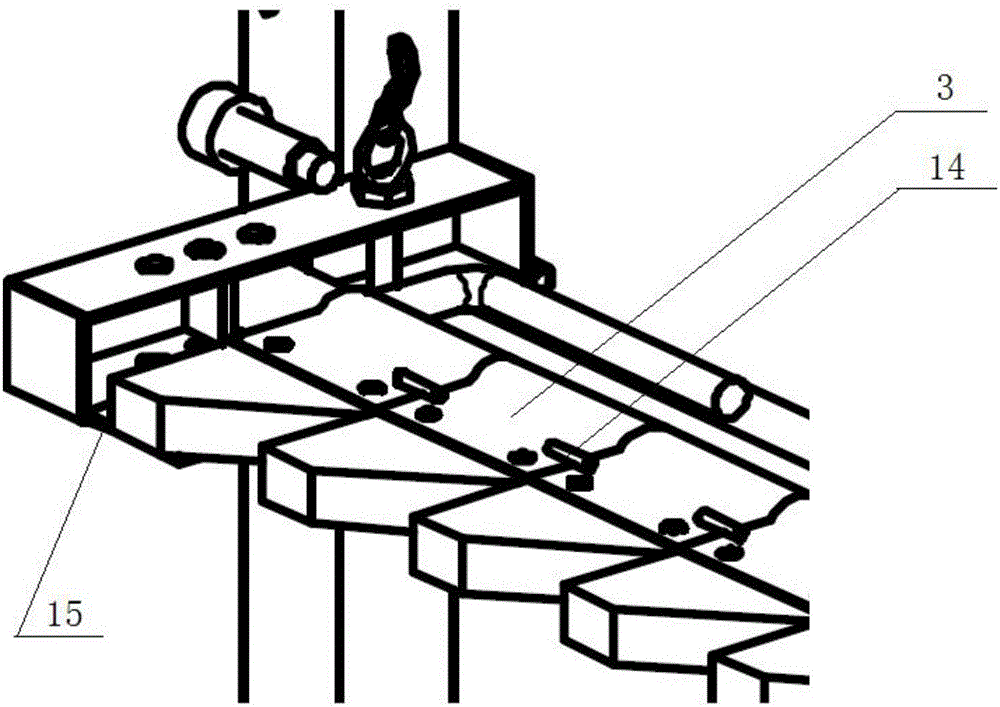

[0036] Such as figure 1 As shown in , a support arm mechanism of a universal transport platform for an engine cover includes a column 7, a mounting frame 1, a support shaft 2, a limit block mounting seat 3, and a soft limit block 4. On the four columns 7 of the engine cover turnover storage rack, the installation frame of this side limit mechanism is symmetrically fixed on the two columns of each side. The mounting frames are groove-shaped, and support shafts are installed between the symmetrical mounting frames, and the ends of the support shafts are embedded in the groove-shaped space of the mounting frames.

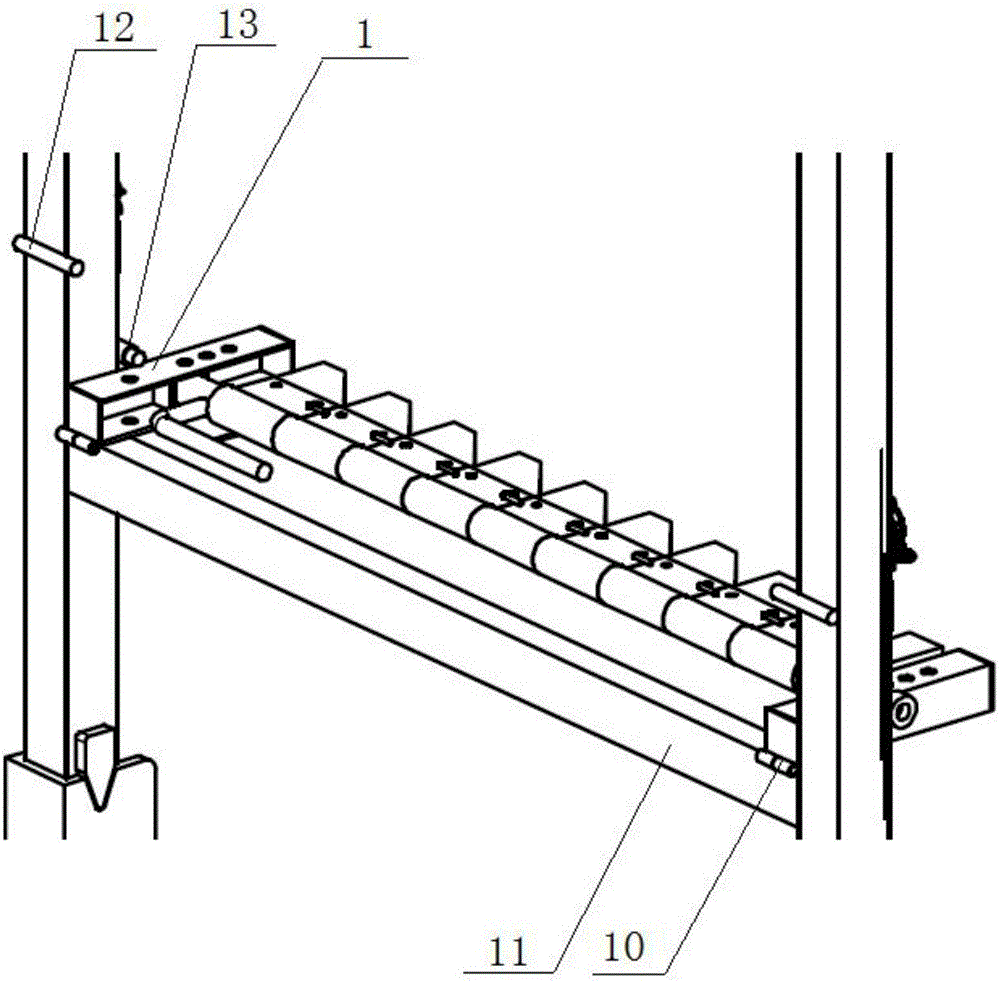

[0037] Such as Figure 4 , 5 , Shown in 6, the limit block mounting seat is a flip-type sliding sleeve on the support shaft, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com