Photoelectrochemical three-dimensional processing method and device of laser bubble cavitation

A technology of photoelectrochemistry and processing methods, applied in the direction of electric processing equipment, processing electrodes, laser welding equipment, etc., can solve the problems of laser energy loss, difficult to achieve effective transmission of laser energy, etc., and achieve slow reaction speed, fast reaction speed, erosion The effect of removing small amounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

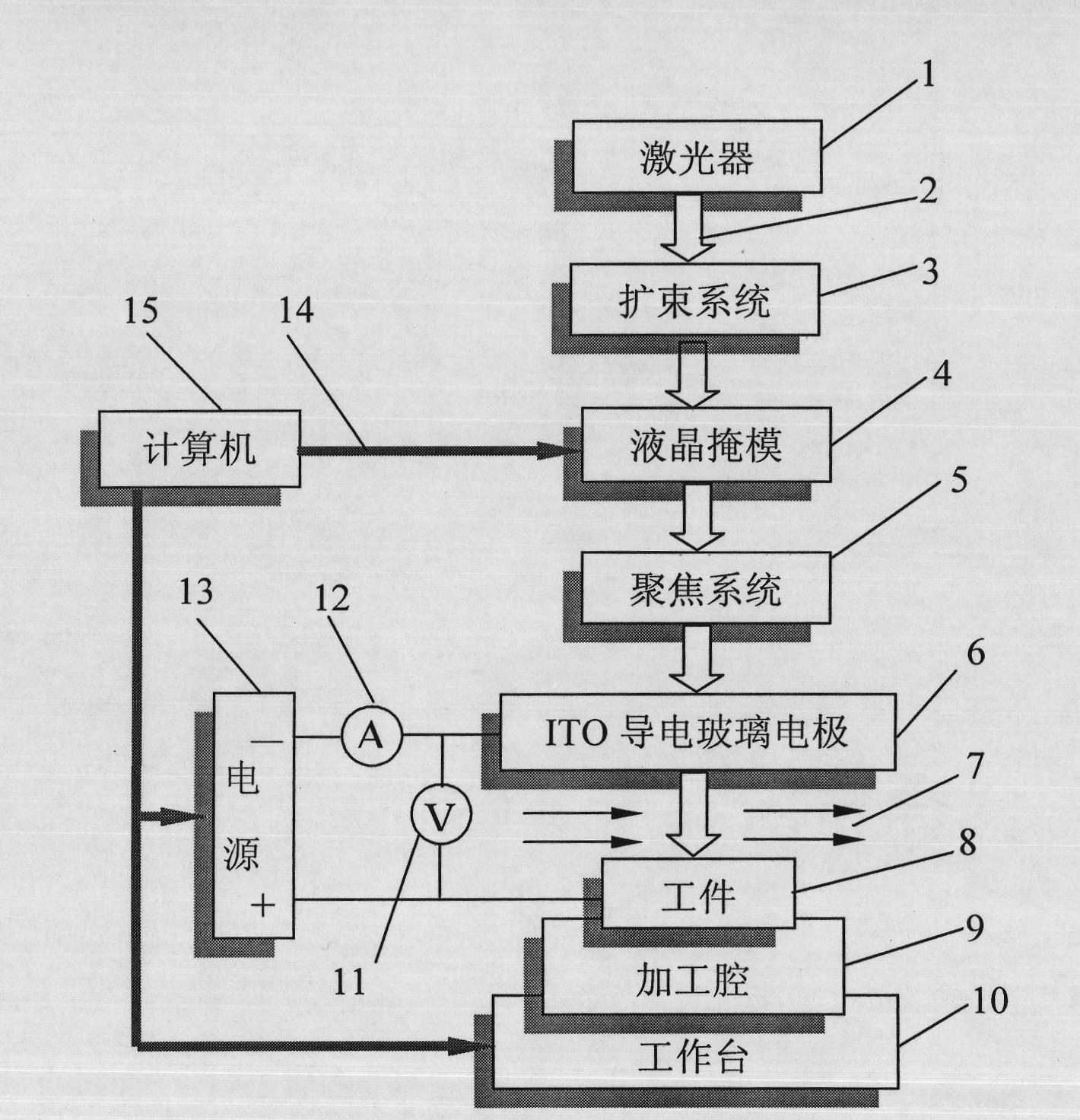

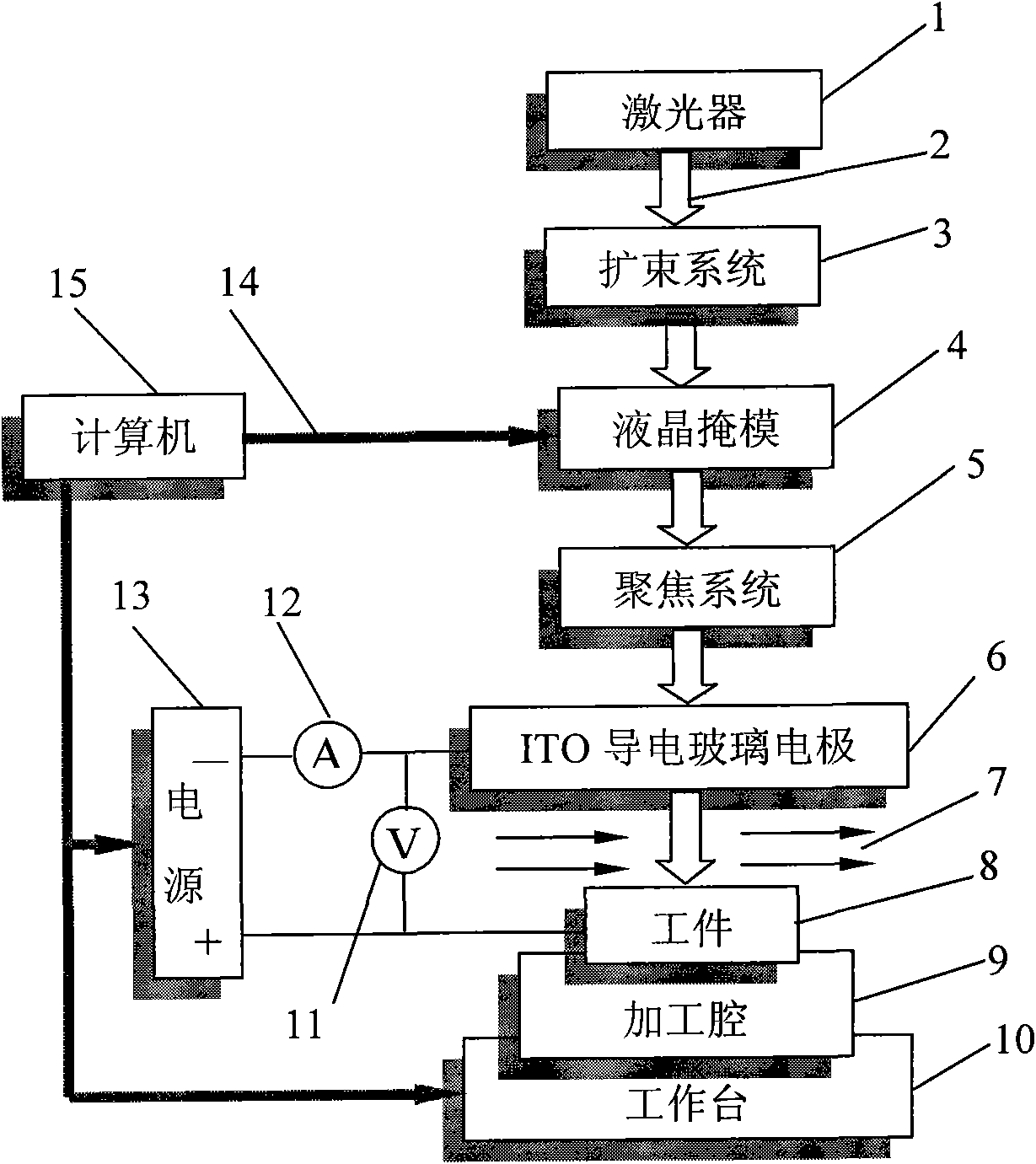

[0028] Embodiment: combine below figure 1 The operation and embodiment of the present invention will be described in detail.

[0029] The device for implementing the method includes sequentially connected lasers 1, transmission light paths and compound processing and detection parts. The transmission optical path includes: beam expander system 3, liquid crystal mask 4, focusing system 5 and ITO conductive glass electrode 6; the composite processing and detection part consists of conductive glass electrode 6, workpiece 8, processing chamber 9, workbench 10, voltmeter 11, Ammeter 12 and processing power supply 13 form.

[0030] The laser generates a laser beam 2 with an energy of 0.1-1 joule, a pulse time of 5 nanoseconds, and a wavelength of 1064 nanometers, and the mode of the laser spot is fundamental or multi-mode. The role of the laser is to control the active area of the photoelectrochemical reaction, increase the reaction current and reaction speed, so the power densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com