A kind of cerium-based rare earth polishing powder and its preparation method and application

A rare earth polishing powder, cerium-based technology, used in grinding/polishing equipment, polishing compositions containing abrasives, manufacturing tools, etc., can solve the problem of insufficient surface erosion, unstable grain growth, and uneven particle size. and other problems, to achieve the effect of improving the physical and chemical properties of particles, high erosion amount, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

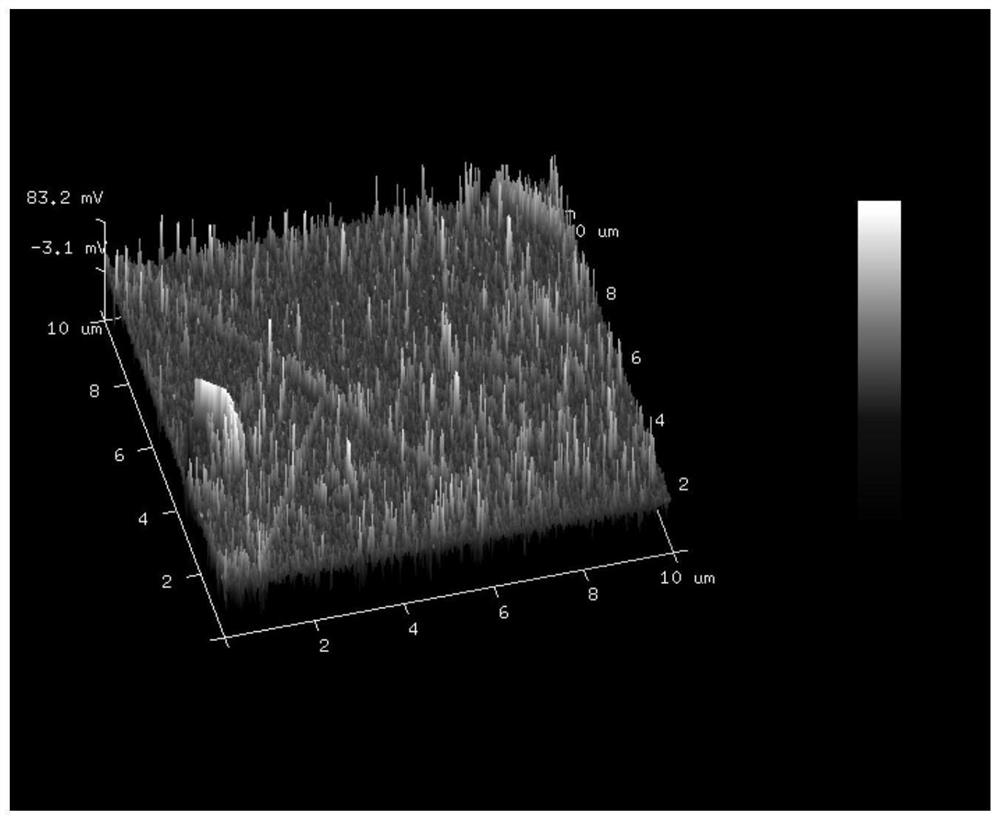

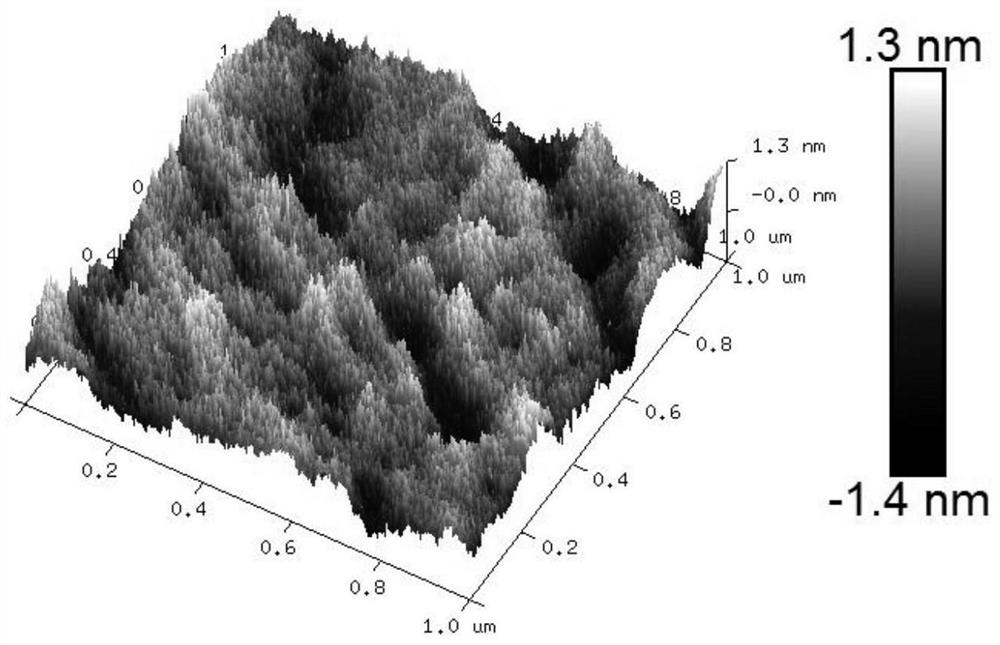

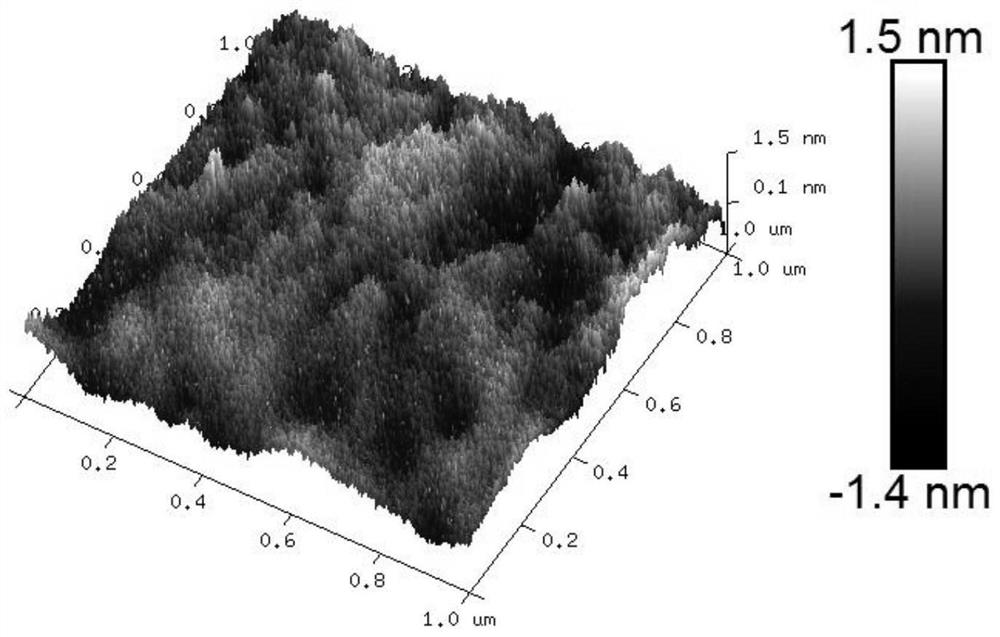

Image

Examples

Embodiment 1

[0031] This embodiment provides a preparation method of cerium-based rare earth polishing powder, which includes the following steps: using cerium carbonate as raw material, mixing with water according to a water-to-material ratio of 1:1, and mixing it in a high-energy ball mill (the input energy form is vibration input energy) , the input energy value is 50Hz, the ball-to-material ratio is 10:1, and the diameter of the grinding beads is about 0.5mm). 50 2.2±0.1μm, release the ball mill slurry, and control the solid content to 50% through the increase or decrease of water, then let the ball mill slurry enter the roller kiln, and bake it at 150°C, 300±15°C, 450±15°C ℃ and 850±15℃ for 4.0 hours respectively. After the calcination, use the furnace air to cool to below 200 ℃ or direct water cooling (quenching) after the calcination, and then use spray drying to dry the cooled powder, and then The spray-dried powder is refined and classified by jet mill to obtain the median particl...

Embodiment 2

[0033] The present embodiment provides a preparation method of cerium-based rare earth polishing powder, which comprises the following steps: using fluoride lanthanum cerium carbonate as raw material, mixing with water according to the water-to-material ratio of 1:1, in a high-energy ball mill (the input energy form is Vibration input energy, the input energy value is 50Hz, the ball-to-material ratio is 10:1, and the diameter of the grinding beads is about 0.5mm) for ball milling to D 50 2.2±0.1μm, release the ball mill slurry, and control the solid content to 50% through the increase or decrease of water, then let the ball mill slurry enter the roller kiln, and bake it at 150℃, 375±15℃, 580±15 ℃ and 975±15℃ for 4.0 hours respectively. After the calcination, use the furnace air to cool to below 200 ℃ or direct water cooling (quenching) after the calcination, and then use spray drying to dry the cooled powder, and then The spray-dried powder is refined and classified by jet mil...

Embodiment 3

[0035] The present embodiment provides a preparation method of cerium-based rare earth polishing powder, which comprises the following steps: using lanthanum cerium carbonate as raw material, mixing with water according to the water-to-material ratio of 1:1, in a high-energy ball mill (the input energy form is vibration input Energy, the input energy value is 50Hz, the ball-to-material ratio is 10:1, and the diameter of the grinding beads is about 0.5mm) for ball milling to D 50 2.2±0.1μm, release the ball mill slurry, and control the solid content to 50% through the increase or decrease of water, then let the ball mill slurry enter the roller kiln, and bake it at 150℃, 350±15℃, 450±15 ℃, 875±15℃, after the calcination, use the air cooling with the furnace to below 200 ℃ or direct water cooling (quenching) after the calcination, then use spray drying to dry the cooled powder, and then use jet mill to spray dry The final powder is refined and classified to obtain the median par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com