Rare earth polishing powder and preparation method thereof

A technology of rare earth polishing powder and rare earth carbonate, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of high polishing rate, environmental pollution, increased cost, etc., and achieve low cost, no environmental pollution, and the amount of erosion and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

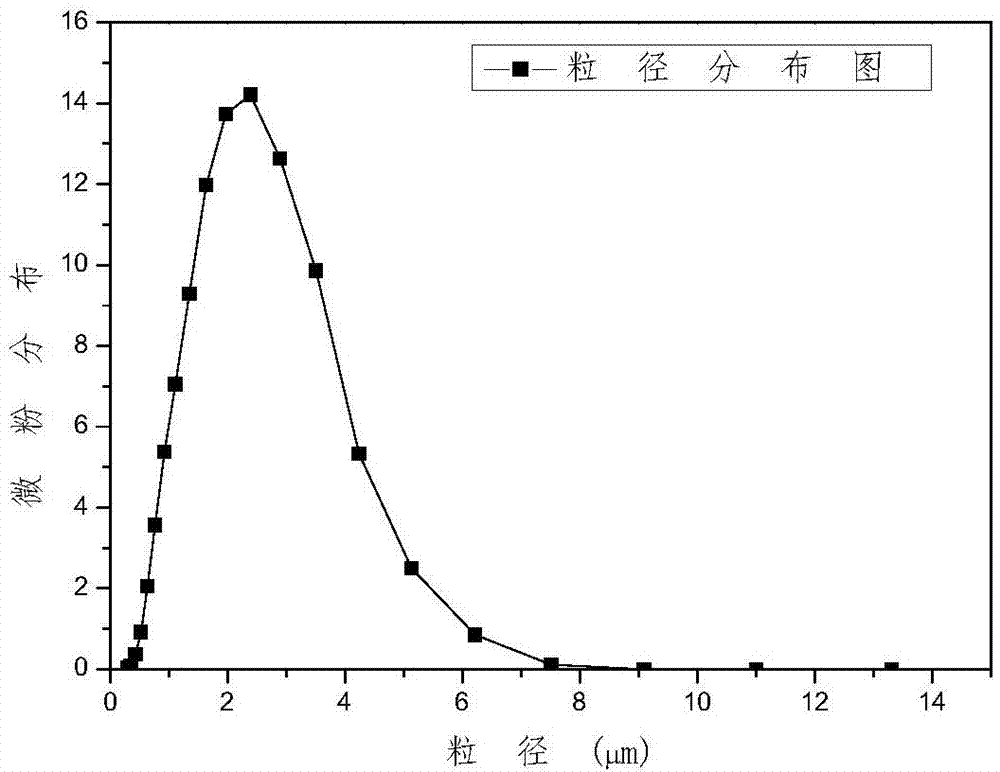

[0034] Under stirring conditions, 80g of lanthanum cerium carbonate (TREO is 45%, CeO 2 / TREO is 60%), 20g kaolin (weight loss on ignition is 15%) are added to 150g water, after ball milling until the D50 is 2.02μm, transfer to the reaction tank, add to 60°C, keep warm for 5h, and keep warm at 120°C for 20h . Then it was calcined at 960°C for 5.5h, and then pulverized by airflow until D50 was 1.51μm to obtain rare earth polishing powder. The mass content of rare earth oxide in the rare earth polishing powder is 68%, and the mass content of aluminum silicate is 32%. figure 1 The particle size distribution diagram of the polishing powder prepared in Example 1.

Embodiment 2

[0036] Under stirring conditions, 90g of lanthanum cerium carbonate (TREO is 45%, CeO 2 / TREO is 63%, Pr 6 o 11 / TREO is 3%), 10g bentonite (weight loss on ignition is 15%) is added to 67g water, after ball milling until D50 is 2.97μm, transfer to the reaction tank, add to 80°C, keep warm for 2h, and keep warm at 180°C for 10h . Then it was calcined at 1030°C for 3.5h, and then crushed by airflow until D50 was 2.98μm to obtain rare earth polishing powder. The mass content of rare earth oxides in the rare earth polishing powder is 82.6%, and the mass content of aluminum silicate is 17.4%.

Embodiment 3

[0038] Under stirring conditions, 85g of lanthanum cerium carbonate (TREO is 45%, CeO 2 / TREO is 70%, Pr 6 o 11 / TREO is 5%), 10g kaolin (weight loss on ignition is 15%), 5g magnesium aluminum silicate (weight loss on ignition is 17%) are added to 170g water, after ball milling until D50 is 2.53μm, transfer to the reaction tank , added to 70°C, kept for 4h, and kept at 160°C for 15h. Then it was calcined at 1000°C for 4.5h, and then pulverized by airflow until D50 was 2.32μm to obtain rare earth polishing powder. The mass content of rare earth oxide in the rare earth polishing powder is 75%, and the mass content of aluminum silicate is 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com