Rare earth and silicon compound precision type rare earth polishing powder and preparation method thereof

A kind of rare earth polishing powder, precision type technology, applied in the direction of polishing composition containing abrasives, etc., can solve the problems of high production cost, low polishing abrasive throwing amount, irreplaceable, etc., and achieve product throwing amount and wear resistance High, simple production process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Under stirring conditions, 111g of cerium carbonate (REO is 45%, CeO 2 / TREO: 99.5%) was added to 500g of deionized water, dissolved with nitric acid to pH=2, filtered to obtain a clear and transparent solution; 25g of precipitated silica and 25g of fumed silica were added to the above solution and stirred for 0.5 After h, heat to 40°C to obtain slurry A;

[0041] Add 100g / L ammonium bicarbonate aqueous solution to slurry A, control the end point to pH 7, to obtain slurry B;

[0042] The slurry B is centrifuged to dehydrate and dried to obtain the precursor C;

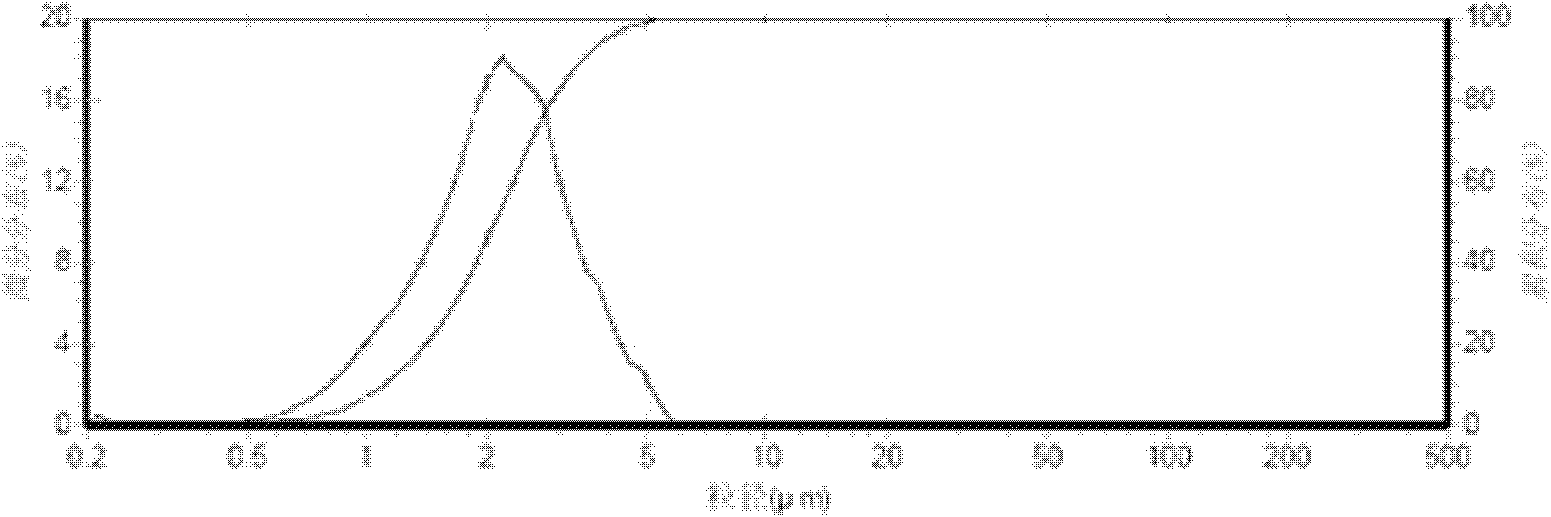

[0043] After calcining C at 950°C for 5 hours, the calcined product is pulverized by airflow to D50=1.99μm, and the target product is a rare earth-silicon compound precision rare earth polishing powder. It is composed of silicon oxide and cerium oxide. Rare earth polishing powder, including: silicon oxide 50%, rare earth oxide 50%.

Embodiment 2

[0045] Under stirring conditions, 167g lanthanum cerium carbonate (REO is 48%, CeO 2 / TREO is 60%) added to 500g deionized water, dissolved with hydrochloric acid to pH=2, filtered to obtain a clear and transparent solution;

[0046] Add 5g fumed silica, 10g quartz powder, and 5g silica powder to the above solution, stir for 1 hour and then heat to 80°C to obtain slurry A;

[0047] Add 200g / L ammonium bicarbonate aqueous solution to slurry A, control the end point to pH 8, to obtain slurry B;

[0048] The slurry B is centrifuged to dehydrate and dried to obtain the precursor C;

[0049] After C is calcined at 1050°C for 3 hours, the calcined product is pulverized by airflow to D50=3.0 μm to obtain the target product, a rare earth-silicon composite precision rare earth polishing powder, which is a rare earth polishing powder composed of silicon oxide and lanthanum cerium oxide. Silicon oxide 20%, rare earth oxide 80%.

Embodiment 3

[0051] Under stirring conditions, 211g lanthanum cerium praseodymium carbonate (REO is 45%, CeO 2 / TREO is 65%) was added to 500g deionized water, dissolved with nitric acid to pH=2, filtered to obtain a clear and transparent solution; 5g precipitated silica was added to the above solution, stirred for 0.5h and heated to 60℃, To obtain slurry A;

[0052] Add 100g / L ammonium bicarbonate aqueous solution to slurry A, control the end point to pH 7, to obtain slurry B;

[0053] The slurry B is centrifuged to dehydrate and dried to obtain the precursor C;

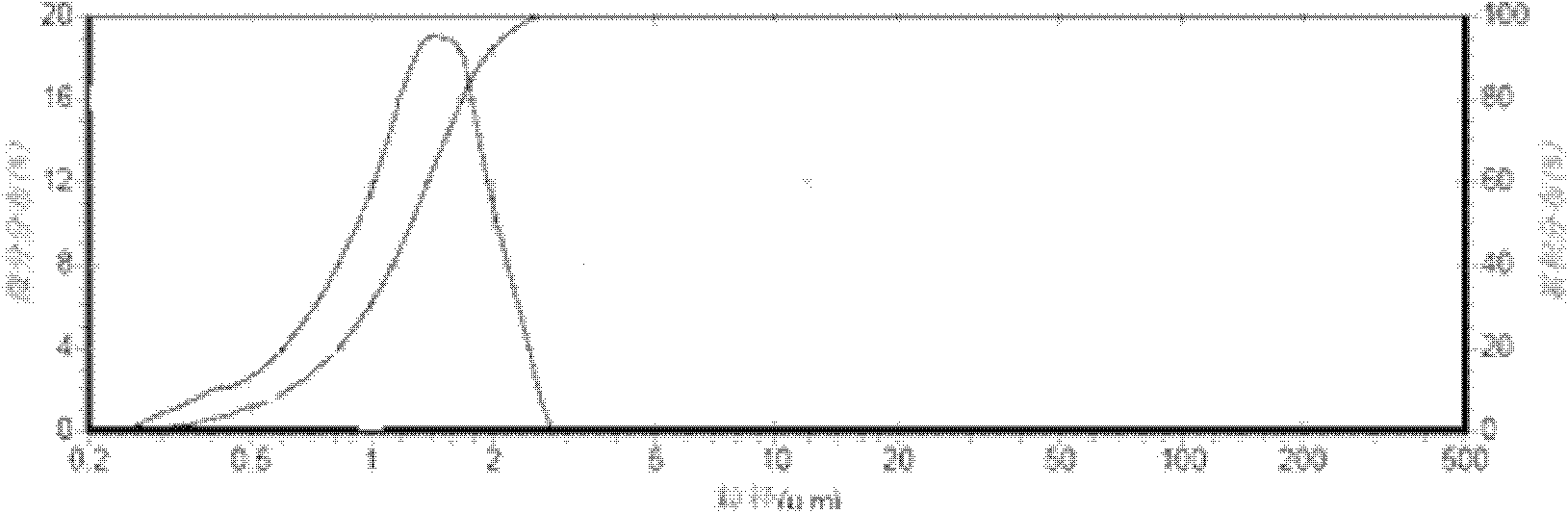

[0054] After calcining C at 950°C for 6 hours, the calcined product is pulverized by airflow to D50=1.2μm, and the target product is a precision rare earth polishing powder composed of rare earth-silicon compound, which is a rare earth polishing powder composed of silicon oxide and lanthanum cerium praseodymium . 5% silicon oxide, 95% rare earth oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com