Fiber cake grabbing fixture and automatic fiber cake stacking system and method

A jig and silk cake technology, applied in the stacking of objects, destacking of objects, conveyor objects, etc., can solve problems such as low efficiency, and achieve the effect of improving stacking efficiency, reducing weight and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

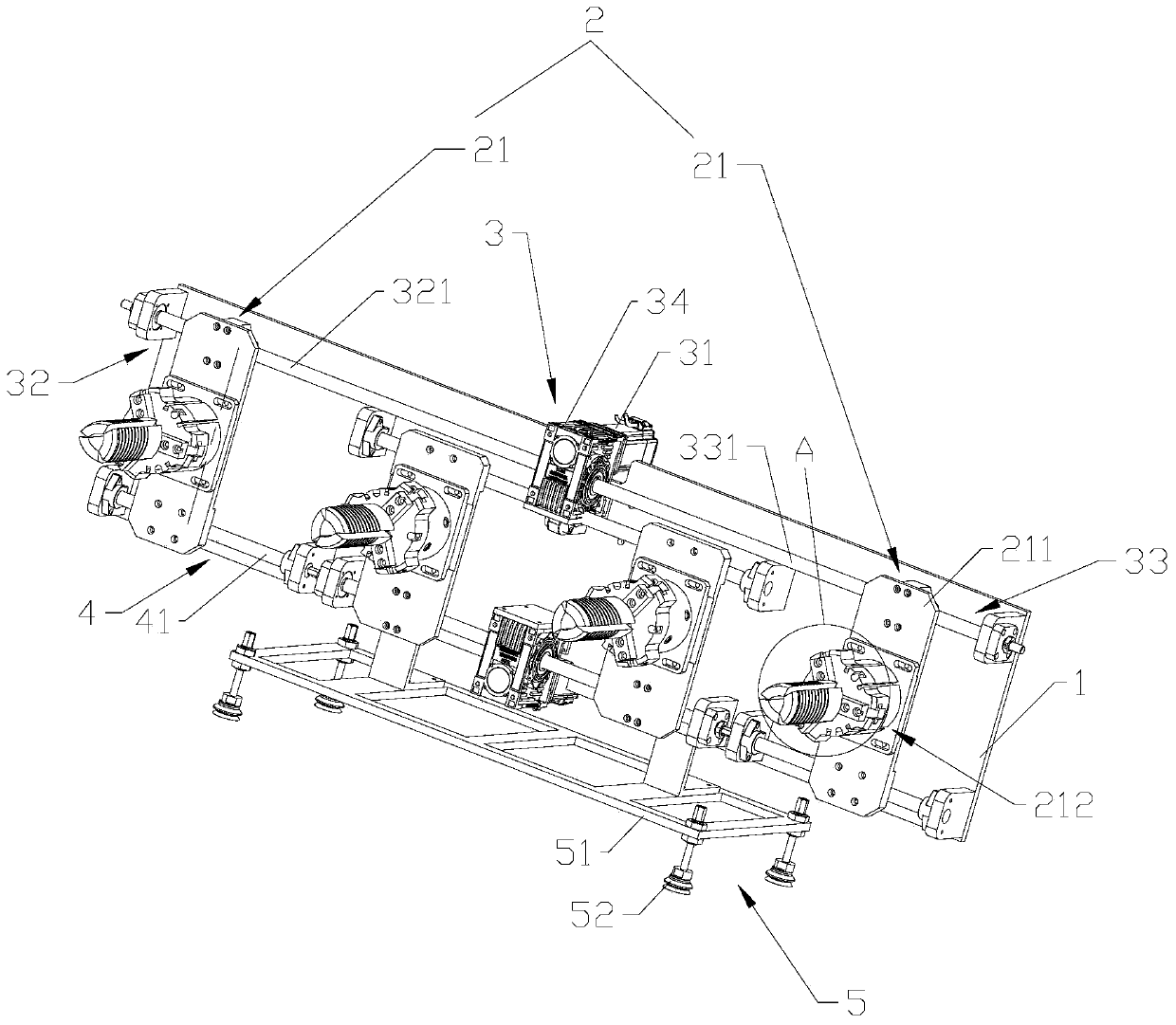

[0054] refer to figure 1 , the present embodiment discloses a fiber cake grabbing jig, including a jig bottom plate 1, at least one jaw set 2 and a drive assembly 3 corresponding to each jaw set 2 are arranged on the jig bottom plate 1, and the jaw set 2 It includes two gripper assemblies 21 arranged at intervals, and the drive assembly 3 drives the two gripper assemblies 21 to approach or move away from each other at the same time. In this embodiment, two sets of jaw sets 2 are provided.

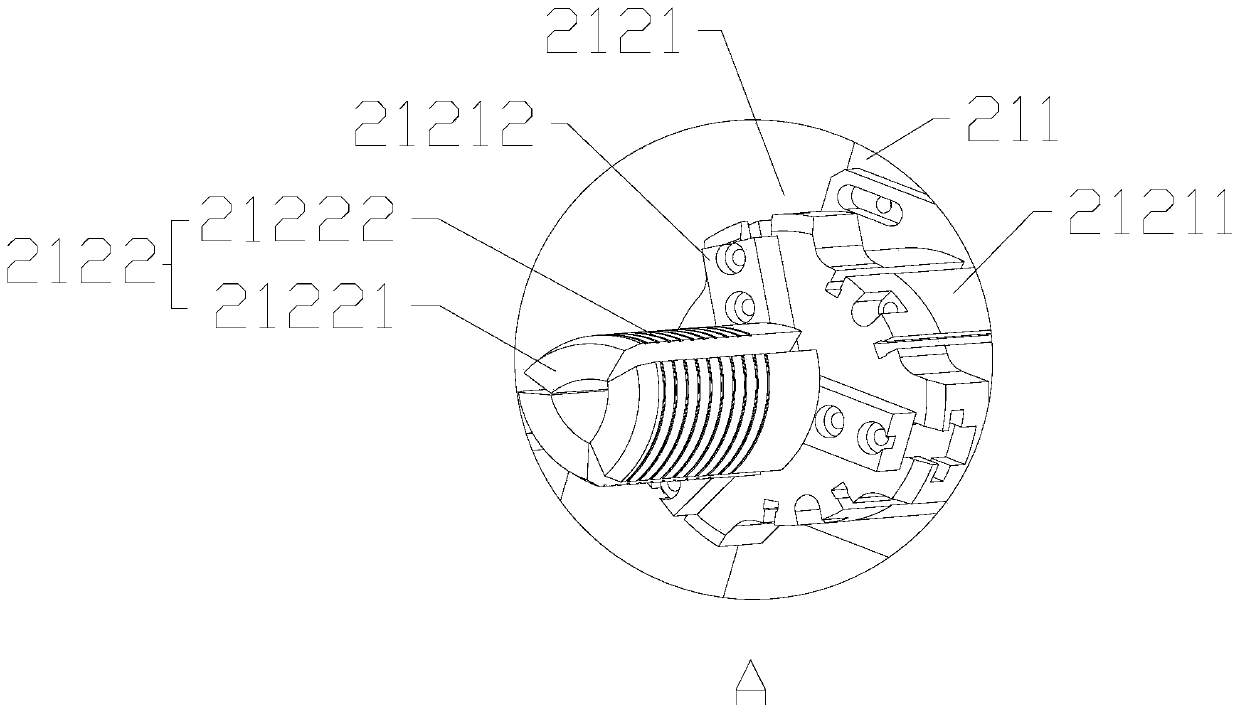

[0055] Each clamp assembly 21 includes a clamp base 211 and a wire extraction assembly 212 , and the wire extraction assembly 212 is disposed on the clamp base 211 .

[0056] refer to figure 1 and figure 2 , each wire taking assembly 212 includes a three-jaw air claw 2121 and three jaws 2122, the three-jaw air claw 2121 is a parallel opening and closing type three-jaw air claw 2121, and the three-jaw air claw 2121 includes an air claw seat 21211 and three The air claw 21212 arranged on ...

Embodiment 2

[0071] Based on Embodiment 1, this embodiment discloses another fiber cake grabbing fixture, which is different from Embodiment 1 in that the drive assembly of this embodiment is a telescopic element, and the telescopic element is a hydraulic telescopic cylinder or a pneumatic telescopic cylinder. Each clamp assembly is correspondingly provided with a telescopic piece, and the expansion and contraction direction of the telescopic piece is parallel to the moving direction of the clamp assembly.

Embodiment 3

[0073] Based on the above embodiments, this embodiment discloses an automatic yarn cake palletizing system, including a palletizing robot and a fiber cake grabbing jig in any of the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com