Mechanical arm

A technology of manipulators and transmission mechanisms, applied in the field of manipulators, can solve problems such as rough feeding mechanisms, and achieve the effects of saving time, improving production efficiency, and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

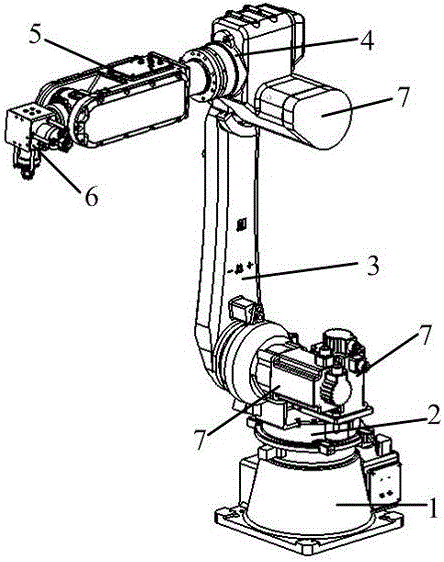

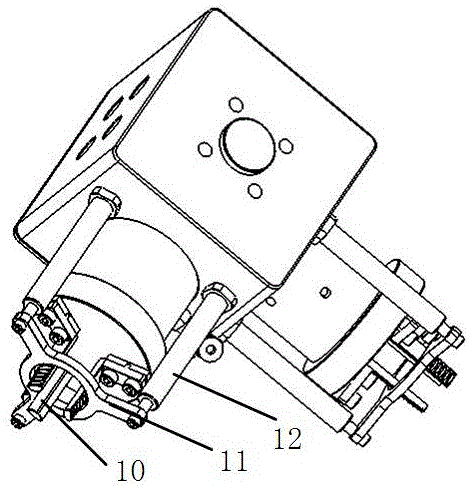

[0026] A manipulator includes a base 1 fixed on a workbench, a swivel waist 2, a large arm 3, a small arm 4, a wrist arm 5 and an actuator 6; the base 1 plays a role of fixing the whole manipulator.

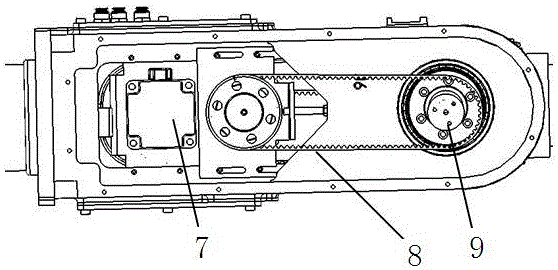

[0027] The swivel waist 2 is set on the base 1, and the motor 7 in the base 1 drives the swivel waist 2 to rotate coaxially on the base 1 through the planetary gear reducer; the planetary gear reducer includes an outer ring 14 and an inner ring 13 on the same axis , and several planetary gears 15 arranged between the outer ring 14 and the inner ring 13 . Powered by the motor 7, the rotation speed and angle of the slewing waist 2 are adjusted through the planetary gear reducer, and the deceleration function is completed through the coordination of the number of teeth between the 9 gears.

[0028] The two ends of the boom 3 are pivotally conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com