Non-uniform structure thick plate welding joint low-cycle fatigue performance testing method

A low-cycle fatigue, welded joint technology, applied in the direction of testing material hardness, using stable tension/pressure to test material strength, etc., to achieve reliable data support and improve the accuracy of life evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

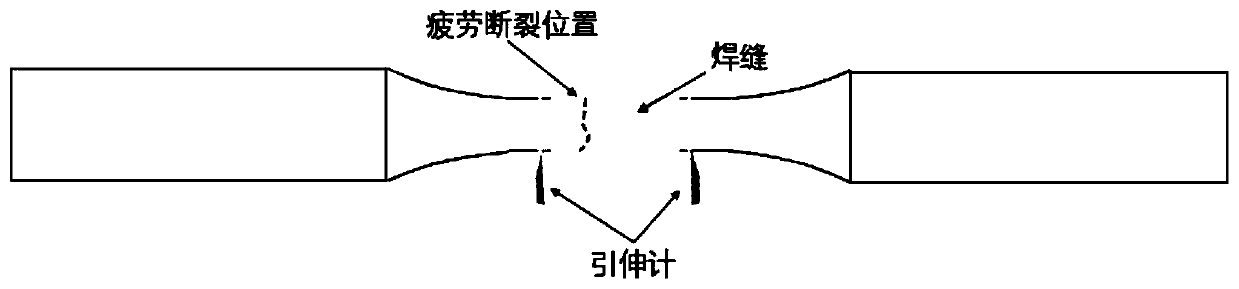

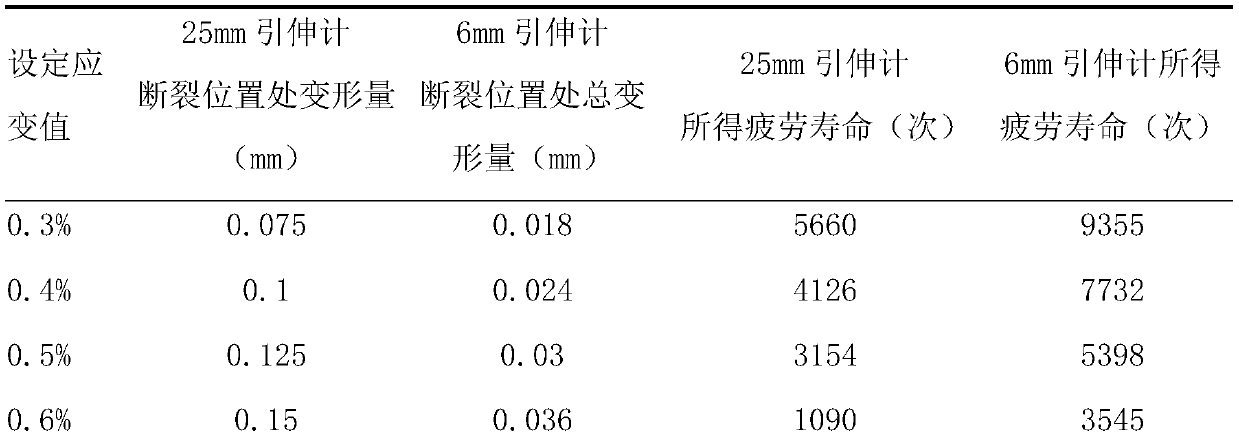

[0053] In the first step, for the low-cycle fatigue test of thick plate welded joints with a width of 20 mm, the center of the weld is selected as the symmetrical line to process three standard low-cycle fatigue samples. The samples are round bars with a diameter of 8 mm in parallel sections; The gage length of the gauge is 25 mm, and two samples are selected to test the low-cycle fatigue fracture position of the joint under low-strain amplitude and high-strain According to the phase structure, it is judged that the fracture position is basically in the heat-affected zone of the weld.

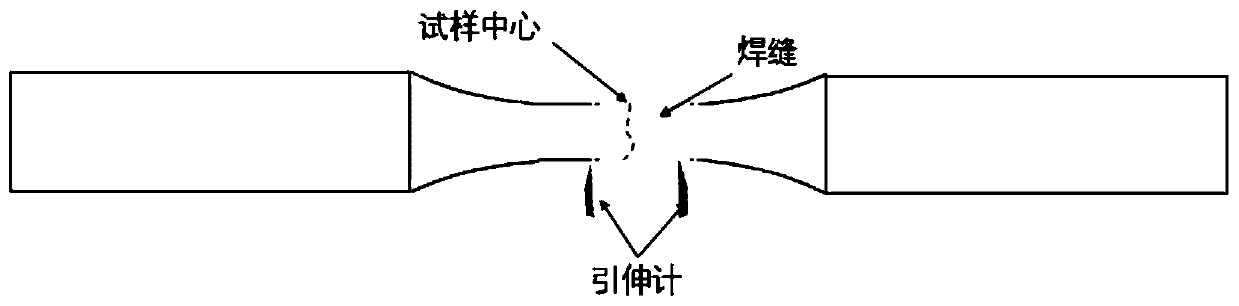

[0054] In the second step, stretch the remaining low-cycle fatigue sample on a static tensile testing machine, observe the fracture position during stretching, and observe the corrosion of the fractured sample, combined with the metallographic structure of the welded joint, again It is determined that the fracture position of the tensile specimen is in the heat-affected zone of the weld.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com