High-temperature and low-temperature fatigue test apparatus suitable for thin fatigue specimen plate

A technology of fatigue test and fatigue test, which is applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve the problem of affecting the accuracy of test test results, fixtures that cannot meet the requirements of the test, clamping end Easy to crack and loosen, achieve high operational reliability and safety, simple structure, and simple sample clamping operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

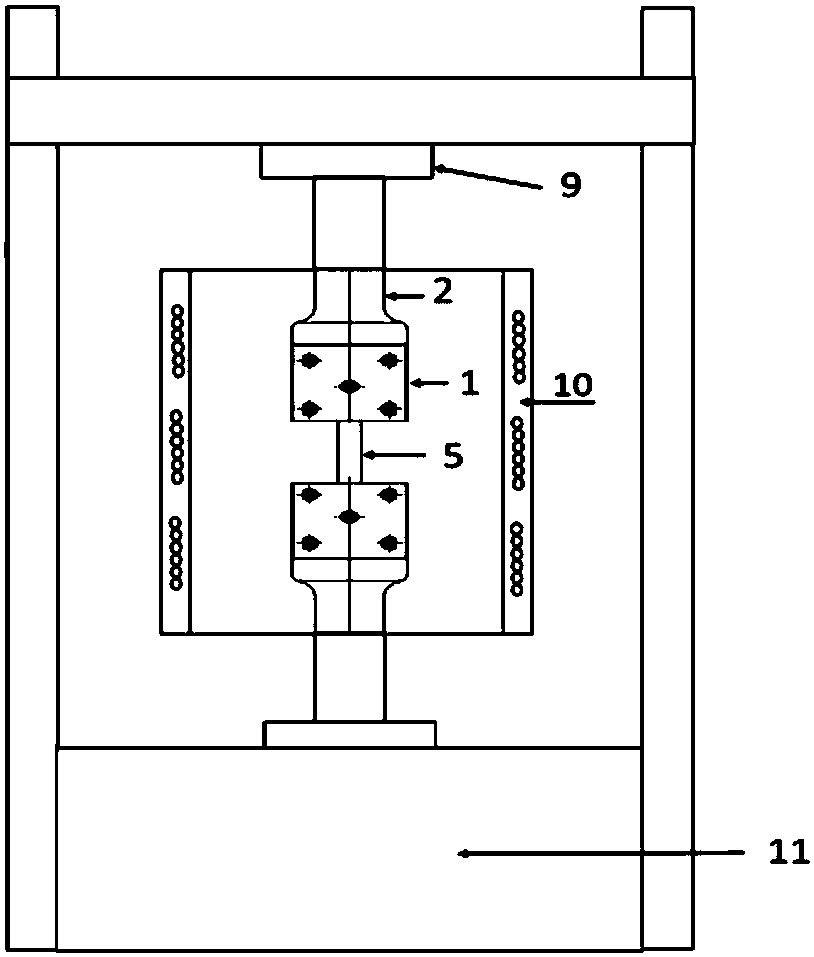

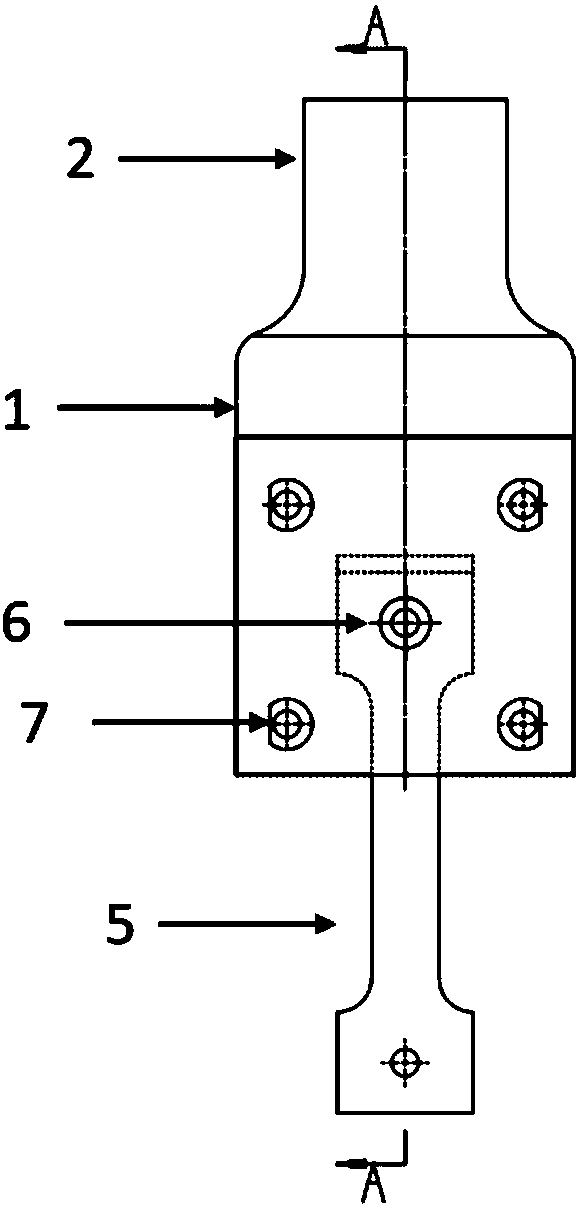

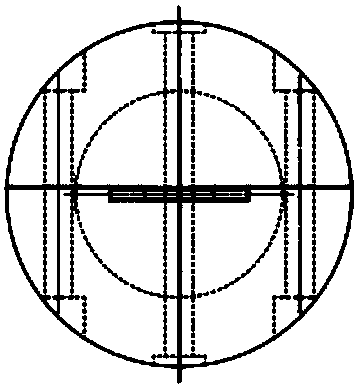

[0025] Such as figure 1 As shown, a high and low temperature fatigue test device suitable for thin plate fatigue samples includes a thin plate fatigue sample 5, a chuck 1, a shaft connecting rod 2, a slot 3, a cover 4, a fixture 9, a heating furnace 10 and a fatigue Test machine 11. The clamping groove 3 has a tangential arc transition, the shape of the clamping ends of the thin plate fatigue specimens 5 is the same, and the clamping ends of the thin plate fatigue specimens 5 are just interference fit and embedded in the clamping groove 3; the closing cover 4 and the fixing pin 6 and The bolt 7 cooperates to fix and clamp the thin plate fatigue sample 5 in the clamping groove 3 .

[0026] The concrete steps when device of the present invention is used for carrying out fatigue test are as follows:

[0027] Step 1, the thin plate processes the sample according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com