Sample clamping device for high-temperature high-frequency complicated load loading test

A technology of complex loads and sample clamps, applied in the direction of measuring devices, testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, etc., to achieve simple structure, reliable operation, and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

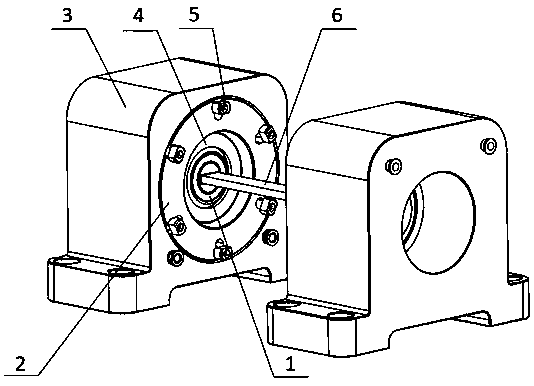

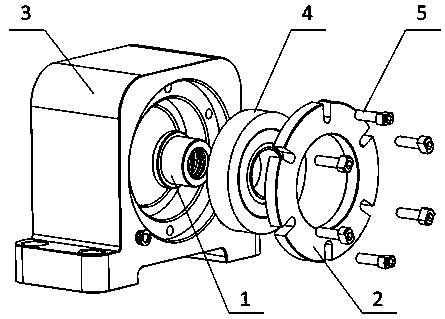

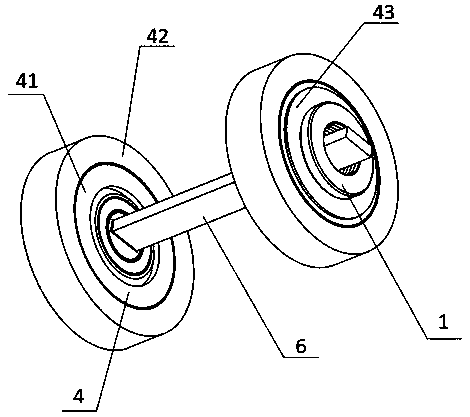

[0024] see Figure 1 to Figure 9 As shown, the sample clamping device for high temperature and high frequency complex load loading test of the present invention can be used on a material testing machine with loading functions such as high temperature, tension, bending, ultrasonic vibration, etc., so that the material testing machine can operate at high temperature ( Room temperature ~ 1100 ℃), high frequency (ultrasonic vibration), complex load (tensile-bending composite loading), the mechanical properties of the test material are close to the service conditions, the structure is simple, the operation is convenient, and it is a key structure in the fields of aviation and aerospace. Material mechanical performance testing provides a strong guarantee. The device is composed of a left fixture and a right fixture wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com