A method and device for preparing static tensile samples of steel wires with a cross-sectional diameter of 2-10mm

A technology for tensile specimens and steel wires, applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problem of inability to accurately obtain conventional mechanical performance indicators, inability to obtain accurate stress and strain values, and difficulty in obtaining effective data guidance Steel wire and other problems, to achieve the effect of good sample performance, simple structure and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: a kind of cross-section diameter 2-10mm steel wire static tensile sample preparation method, comprises the following steps:

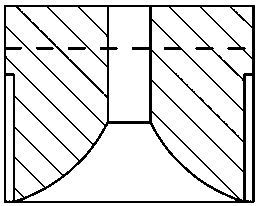

[0029] (1) Sample loading: Pass one end of the steel wire with a cross-sectional diameter of 2-10 mm through the center of the barrel lid of the sample preparation device and then lean against the middle of the bottom side of the drum. The bottom of the barrel lid is set as an arc-shaped transition surface. Sample standard production;

[0030] (2) Casting solution: Put the low-melting point metal Sn into the graphite crucible and heat it to above 232°C in a box furnace to melt it;

[0031] (3) Pouring the metal Sn solution melted in step (2) into the drum in step (1) through the sprue, covering the surrounding of the metal material, and after the metal Sn around the metal material is solidified, remove it from the sample preparation Take it out from the device to obtain one end of the steel wire tensile material sample to complete ...

Embodiment 2

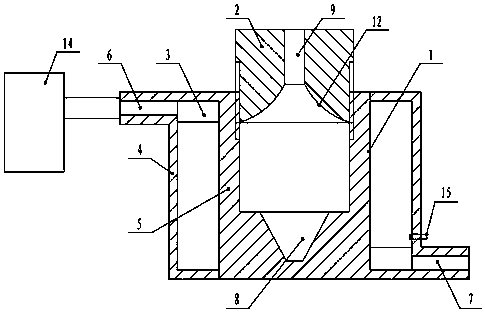

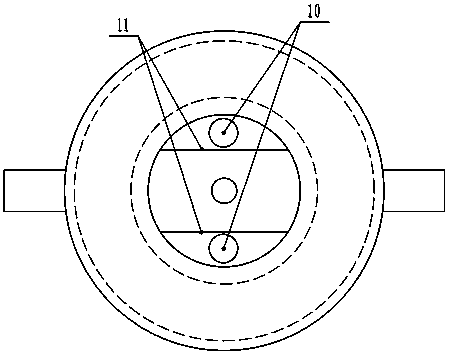

[0037] Embodiment 2: as Figure 1-Figure 5 As shown, a steel wire static tensile sample preparation device with a cross-sectional diameter of 2-10mm includes a drum 1 and a drum cover 2. A blind cone hole 8 for placing a sample is arranged in the middle of the inner bottom of the drum 1, and the upper end is A barrel cover 2 is provided, the barrel wall of which is a hollow cavity 3, the middle part of the barrel cover 2 is provided with a through hole 9 passing through the sample, and the barrel cover 2 is provided with a pouring port 10, and the lower side is provided with a The arc-shaped transition surface 12 protrudes downwards. The cavity 3 includes an outer wall 4 and an inner wall 5 . The outer wall 4 is provided with a water inlet 6 and a water outlet 7 communicating with the cavity 3 .

[0038] Preferably, the above-mentioned barrel cover 2 and the drum 1 are connected by threads, which can be quickly installed and the operation is convenient and fast.

[0039]Prefe...

Embodiment 3

[0044] Embodiment 3: First, brush a layer of demoulding material on the inner wall of the drum of the sample preparation device, then cut the steel wire with a cross-sectional diameter of 2-10mm into a preliminary sample with a minimum length of 5 times the diameter and fix it vertically on the drum and the lid of the sample preparation device After the sample is fixed, put the low-melting point metal Sn into the graphite crucible and melt it through the laboratory box furnace above 232°C. After the metal Sn in the crucible is melted, use crucible tongs to remove it from the In order to prevent the crucible from breaking due to partial cooling, when using crucible tongs to hold a hot crucible, the tip of the tongs must be preheated first, and then the metal Sn solution in the crucible must be scooped out with a spoon. The sprue of the barrel cover in the sample preparation device pours the metal Sn solution around the metal material. In order to avoid the impact of the high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com