Test method for uniaxial constitutive relation of ductile material

A technology of constitutive relation and ductile material, applied in the direction of analyzing materials, applying stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of engineering stress drop and the inability to truly obtain the stress-strain relationship of materials, etc., to achieve The effect of avoiding severe effects, simple and easy method, and wide range of constitutive relations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] A method for testing the uniaxial constitutive relationship of ductile materials, comprising the following steps:

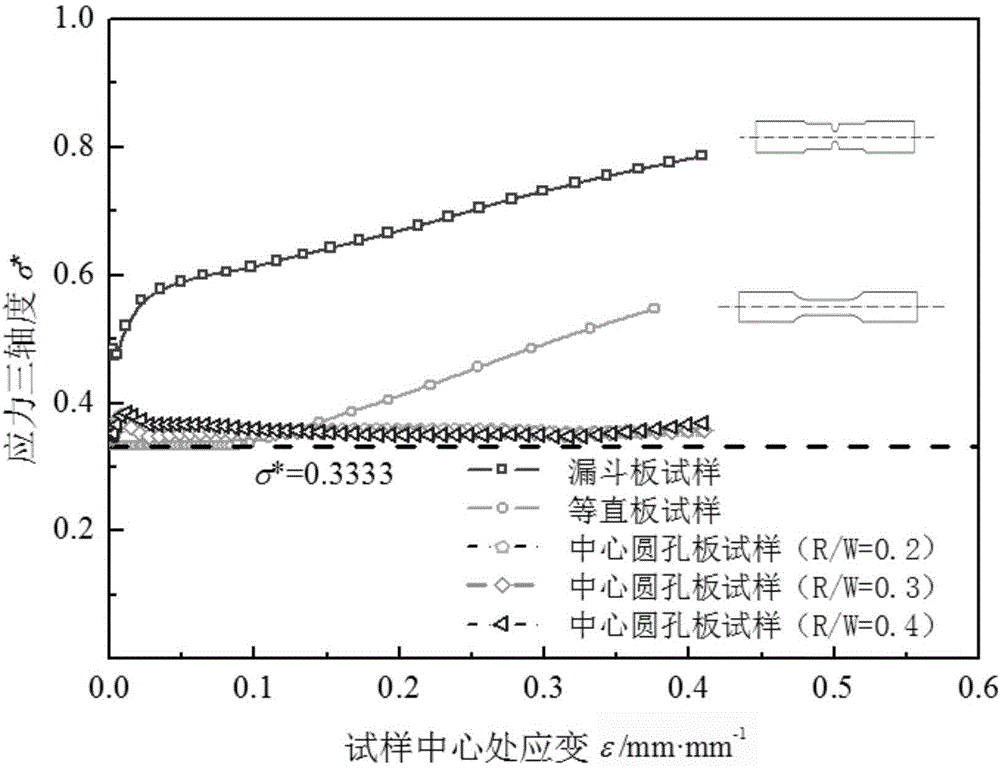

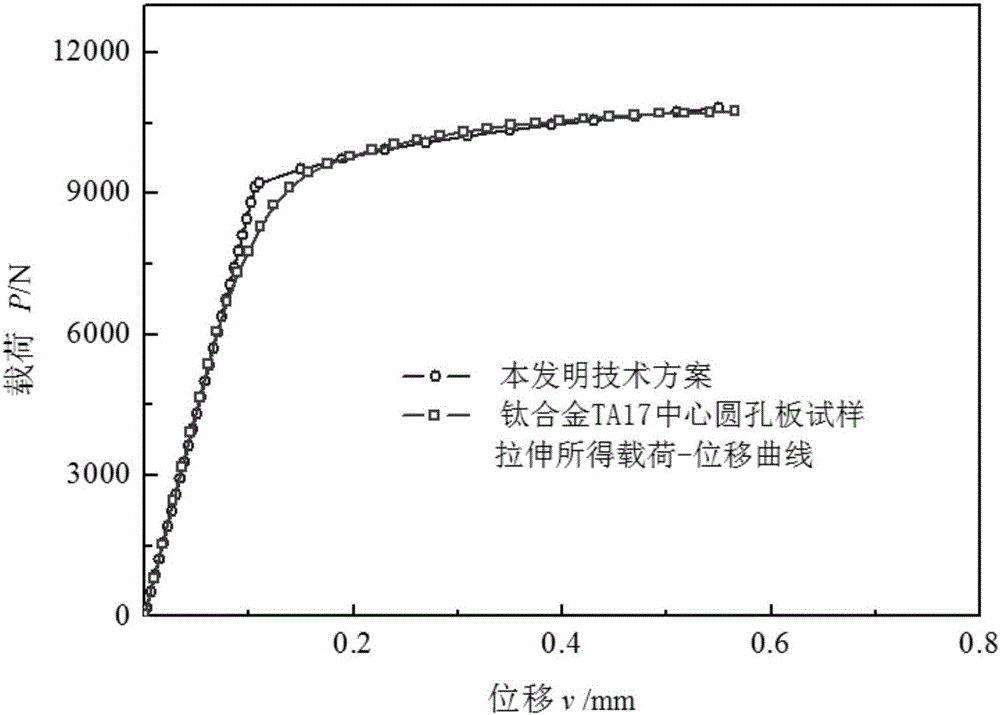

[0031] Through the quasi-static tensile test, the relationship between the continuous load P and the displacement V of the material sample is obtained. The sample is a central circular hole plate sample, and the P-V curve satisfies the following relationship:

[0032]

[0033] In the formula: R sample hole radius, S is the elastic stiffness, P* is the characteristic load, m is the displacement index, V y is the yield displacement of the sample;

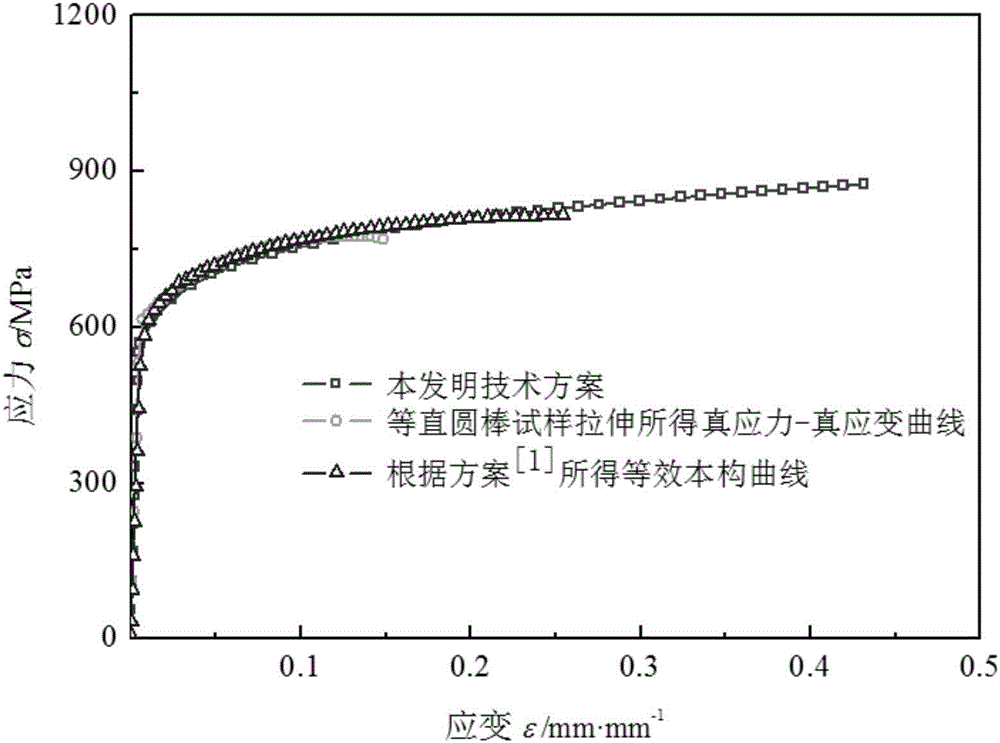

[0034] Obtain the constitutive relation parameters of the material according to S, P* and m, including elastic modulus E, nominal yield stress σ y and the strain hardening exponent n, the critical fracture stress σ is obtained by finite element simulation f and the critical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com