Method for designing optimal back zone draft ratio of drawing frame

A technology of drafting ratio and drawing frame, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of high cost, complicated equipment and operation, and achieve the effect of saving raw materials and accurate methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] It is planned to draw the carded cotton sliver (the weight of a single cotton sliver is 2.39g / m), and the combined number is 6. According to the length of the fiber and other properties, the center distance of the rollers in the rear area of the draw frame is set to 50mm , it is now necessary to determine the optimal draft ratio in the back zone.

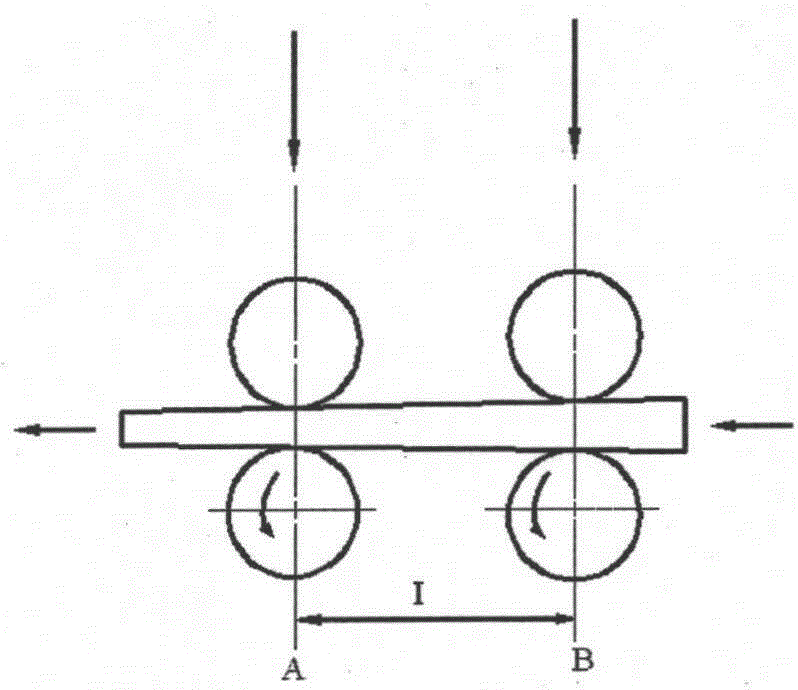

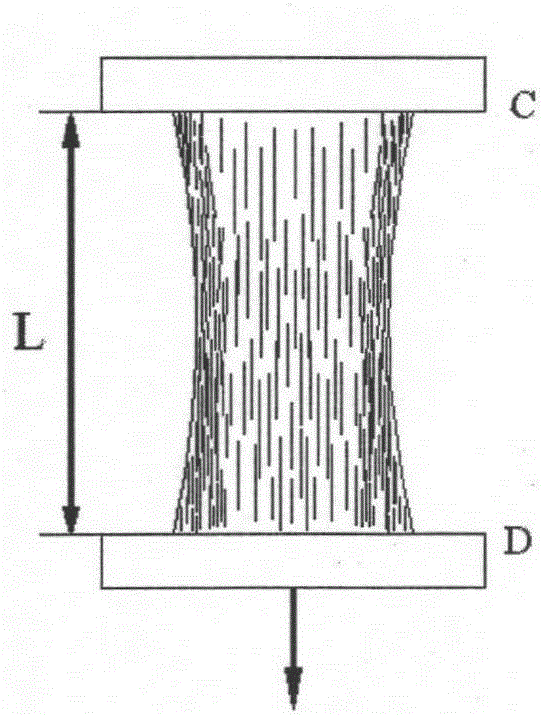

[0042] Firstly, the dynamic drafting is simulated by static stretching. The static drafting is to use the stretching tester to hold the two ends of the sliver respectively, and stretch the cotton sliver at a certain speed to simulate the drafting. The optimal stretching curve is determined according to the stretching curve. The draft ratio of the optimal back zone.

[0043] Stretch 6 cotton slivers (total weight 14.34g / m) on a universal material testing machine, set the clamping distance of the upper and lower chucks to 50mm, and obtain the experimental values of critical tensile force and critical elongation and Tensile...

Embodiment 2

[0049] It is planned to draw the carded cotton sliver (the weight of a single cotton sliver is 2.28g / m), and the number of combined roots is 8. According to the length of the fiber and other properties, the center distance of the rollers in the rear area of the drawing frame is set to 46.6 mm, it is now necessary to determine the draft multiple of the rear area.

[0050] Tensile test was used to stretch 8 cotton slivers (total weight: 19.08g / m), set the clamping distance of the upper and lower chucks to 46.6mm, and obtain the experimental values of critical tensile force and elongation And tensile force and elongation curves are shown in Table 2 and Figure 8 shown.

[0051] Table 2 The maximum tensile force and critical elongation of eight cotton slivers

[0052] Testing frequency

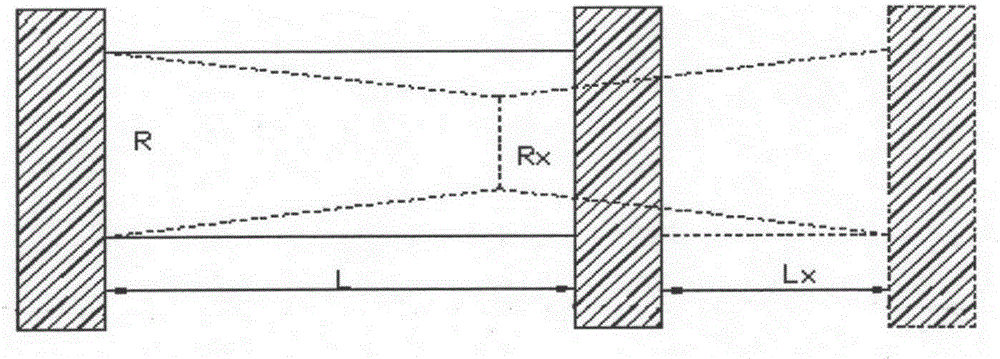

[0053] use the formula Where L is the clamping distance, L x For stretch elongation. Convert the elongation into the draw ratio, and obtain the relationship curve between the ...

Embodiment 1

[0054] Embodiment 1 verification example

[0055] On the DHUA301 drawing frame, feed the sliver with a total weight of 14.31g / m, set the center distance of the rollers in the rear drafting area to 50mm, and set the drafting ratios in the rear area to 1.462, 1.52, 1.583, and 1.652 respectively for drafting Test the force, and measure the CV value of the evenness of the combined sliver on the YG139BA evenness tester. Obtain the experimental data of the draft ratio in the rear area and the draft force and the evenness CV value as shown in table 3, and make the relationship curve between the draft ratio in the rear area and the draft force according to the data in the table Figure 10 shown.

[0056] Table 3 Experimental data of drafting force and evenness CV value under different drafting ratios

[0057] Number of teeth

26

25

24

23

Draft multiples in back zone

1.462

1.52

1.583

1.652

Drawing force(cN)

110.67

127.08 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com