High-temperature ultrasonic fatigue in-situ test instrument and test method

An in-situ testing and ultrasonic technology, used in instruments, scientific instruments, and the use of stable tension/pressure to test the strength of materials, etc., can solve the problems of simple structure, single function, difficult to achieve fatigue performance and deformation damage mechanism, etc. Ease of maintenance and prevention of surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

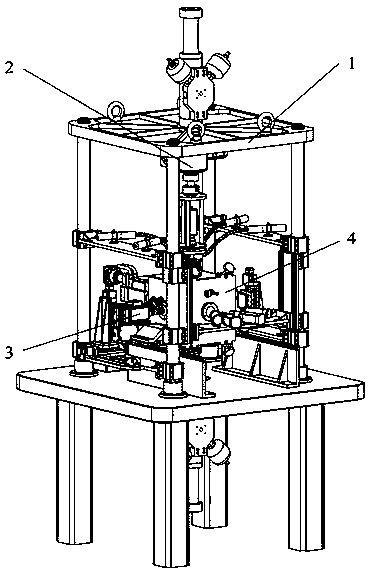

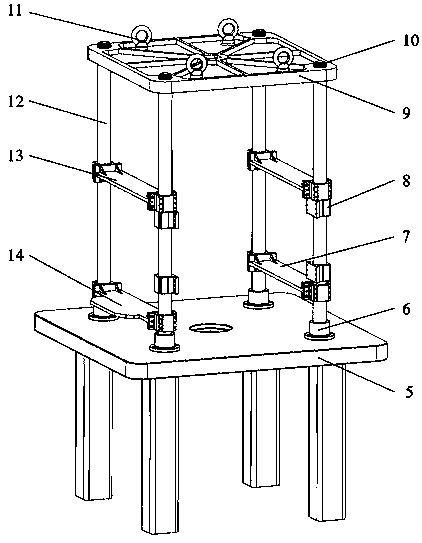

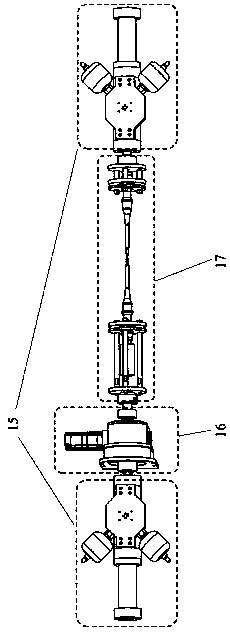

[0050] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0051] see Figure 1 to Figure 19 As shown, the high-temperature ultrasonic fatigue in-situ testing instrument and testing method of the present invention are composed of an overall frame module, a mechanical loading module, a high-temperature loading module and an in-situ monitoring module. Among them: the overall frame module is used for precise positioning of each functional module, while providing stable support and effective vibration isolation; the mechanical loading module is used to simultaneously apply static tensile / compressive loads to both ends of the tested sample, and apply ultrasonic fatigue loads according to the test requirements , and can achieve precise axial indexing; the high-temperature loading module is used to apply high-temperature loads to the tested sample; the in-situ monitoring module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com