Fixing equipment used in production process of laminated glass

A production process, laminated glass technology, applied in layered products, lamination devices, lamination, etc., can solve the problems of glass prone to bubbles, affecting the quality of tempered laminated glass, poor fixing effect, etc., to achieve a simple structure , easy to operate, avoid the effect of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

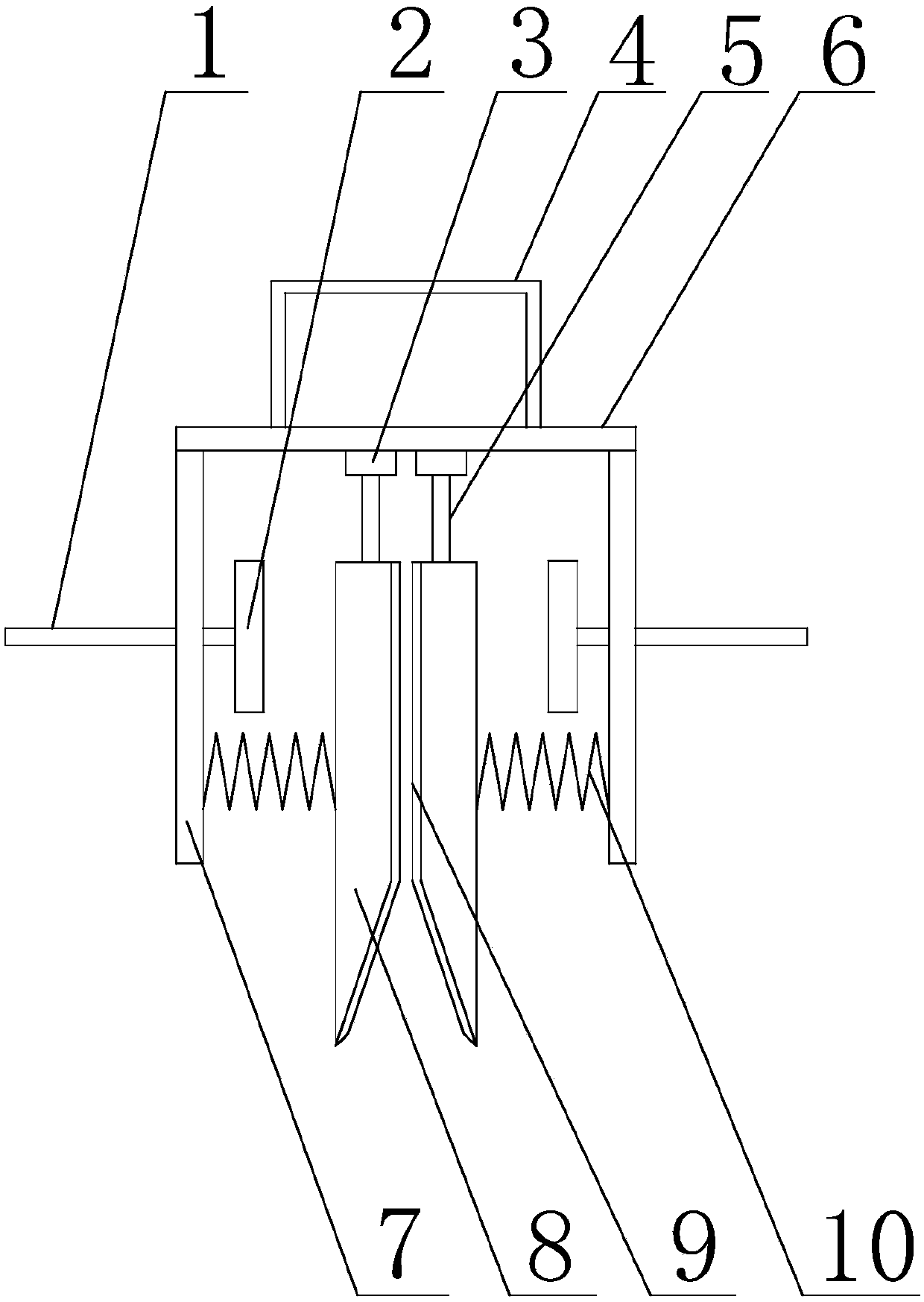

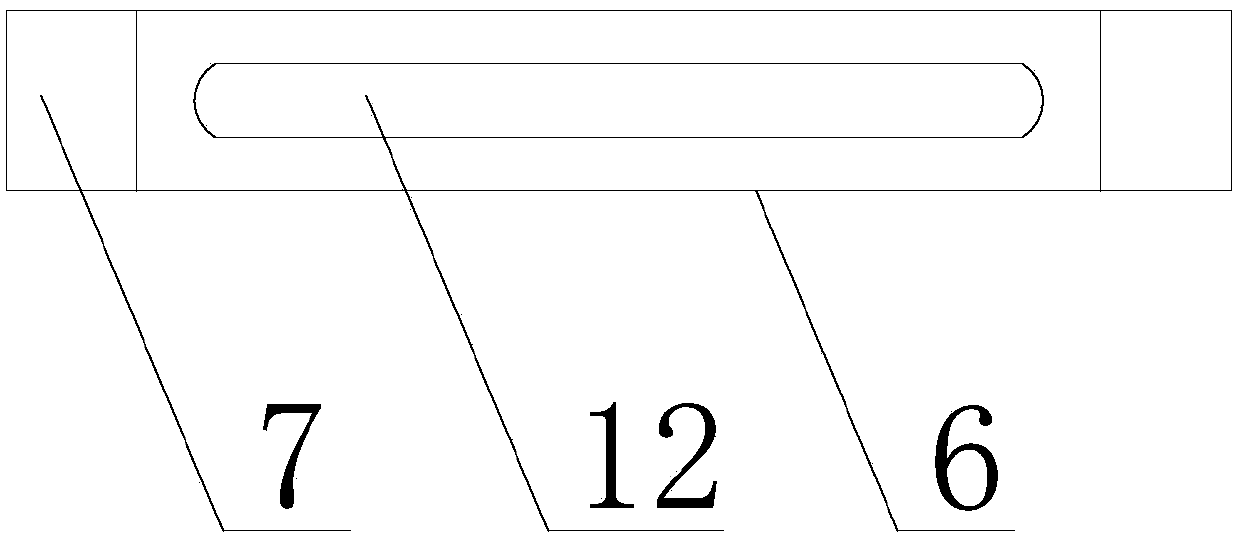

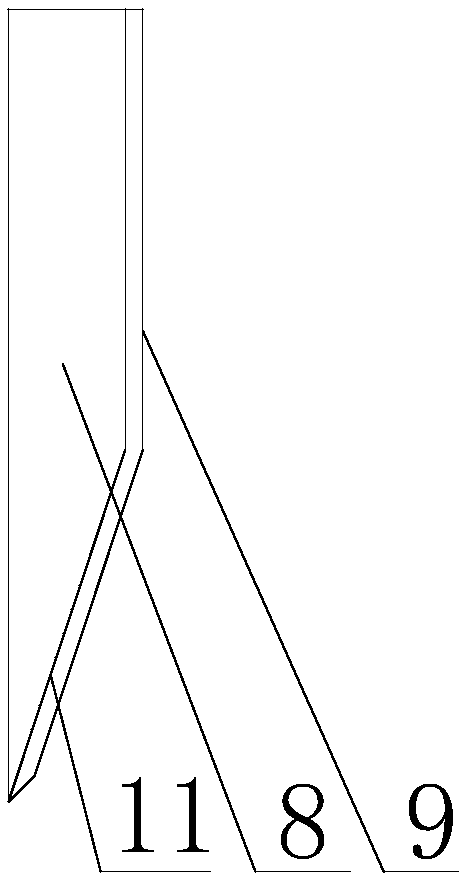

[0026] Such as Figure 1 to Figure 4 As shown, the present invention is used for the fixing equipment in the laminated glass production process, comprises connecting plate 6, and described connecting plate 6 is rectangular shape, and the two ends of connecting plate 6 are all provided with supporting plate 7, and supporting plate 7 and connecting plate 6 welding to ensure that the connection has stronger strength and longer service life. The support plate 7 is provided with an elastic element 10. The elastic element 10 is a spring with good elasticity. One end of the elastic element 10 Connected with the supporting plate 7, the other end is provided with a clamping plate 8, which is used to clamp the glass 13, and the elastic force generated by the elastic element 10 forces the two clamping plates 8 to be pressed together, and the two The glass 13 is placed between the clamping plates 8, and the elastic force generated by the elastic element 10 can press two pieces of glass be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com