Two-jaw clamp

A double-jaw and clamp technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of insufficient rigidity, large vibration, and affecting the service life of saw blades for sawing accuracy, so as to prolong the service life, improve the clamping force, The effect of improving processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

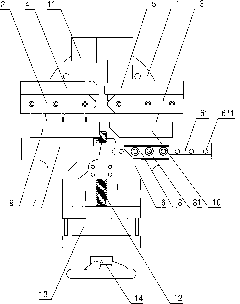

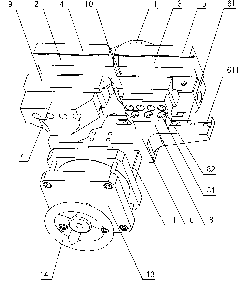

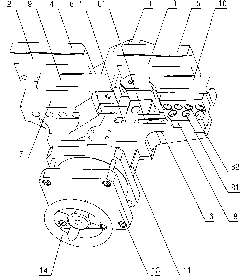

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] like figure 1 , figure 2 As shown, the double-jaw clamp of the present invention includes: a base 1, left and right fixed jaw seats 2 and 3 fixed on the base 1, and left and right fixed jaw seats 2 and 3 are respectively provided with translationally movable The left and right fixed jaw bodies 4 and 5, the base 1 is provided with a pair of guide rails 11, and the pair of guide rails 11 is slidably provided with a sliding seat 6. The specific setting method is: the bottom of the sliding seat 6 is provided with a pair of The chute matched with the guide rail 11, the pair of guide rails 11 are respectively located in the corresponding chute; the base 1 is also provided with a sliding seat translation locking device, and its structure includes: fixed at one end of the pair of guide rails 11 The double-out type clamping oil cylinder 13 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com