Positioning mechanism for electromechanical equipment processing

A positioning mechanism and electromechanical equipment technology, applied in the direction of metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of cumbersome debugging process of clamping positioning mechanism, affecting the production efficiency of electromechanical equipment, affecting the processing quality of workpieces, etc., to achieve Easy to change, simple and convenient to replace, and the effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

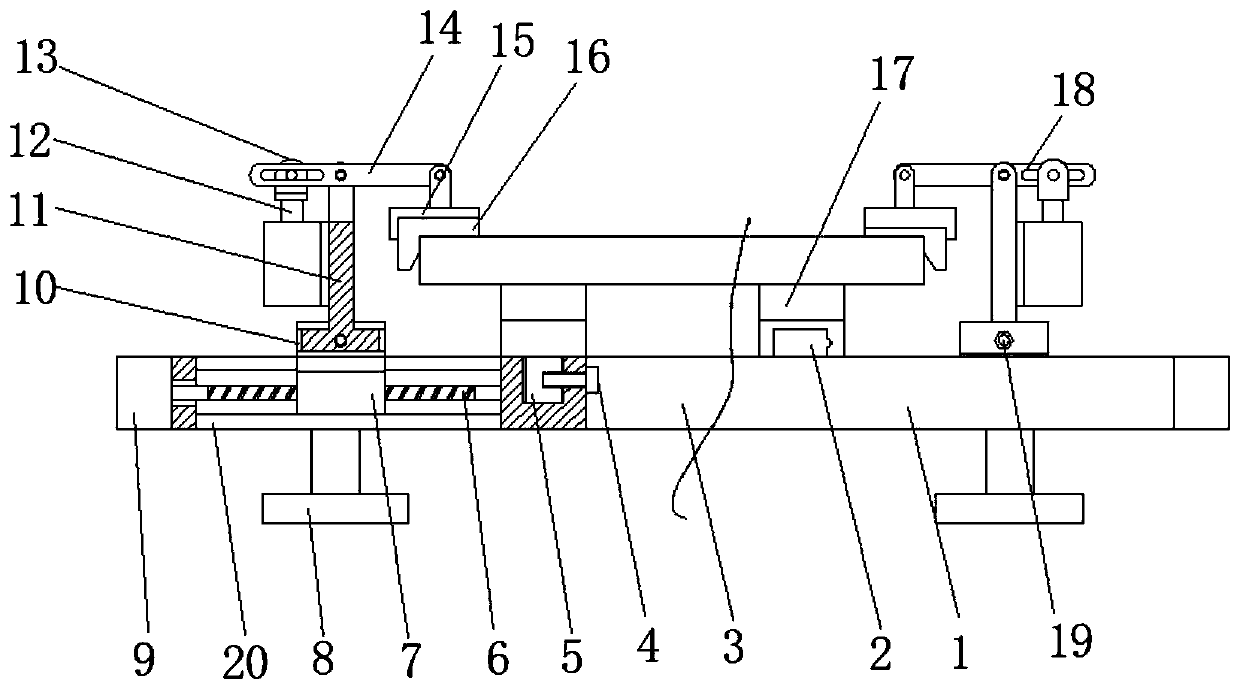

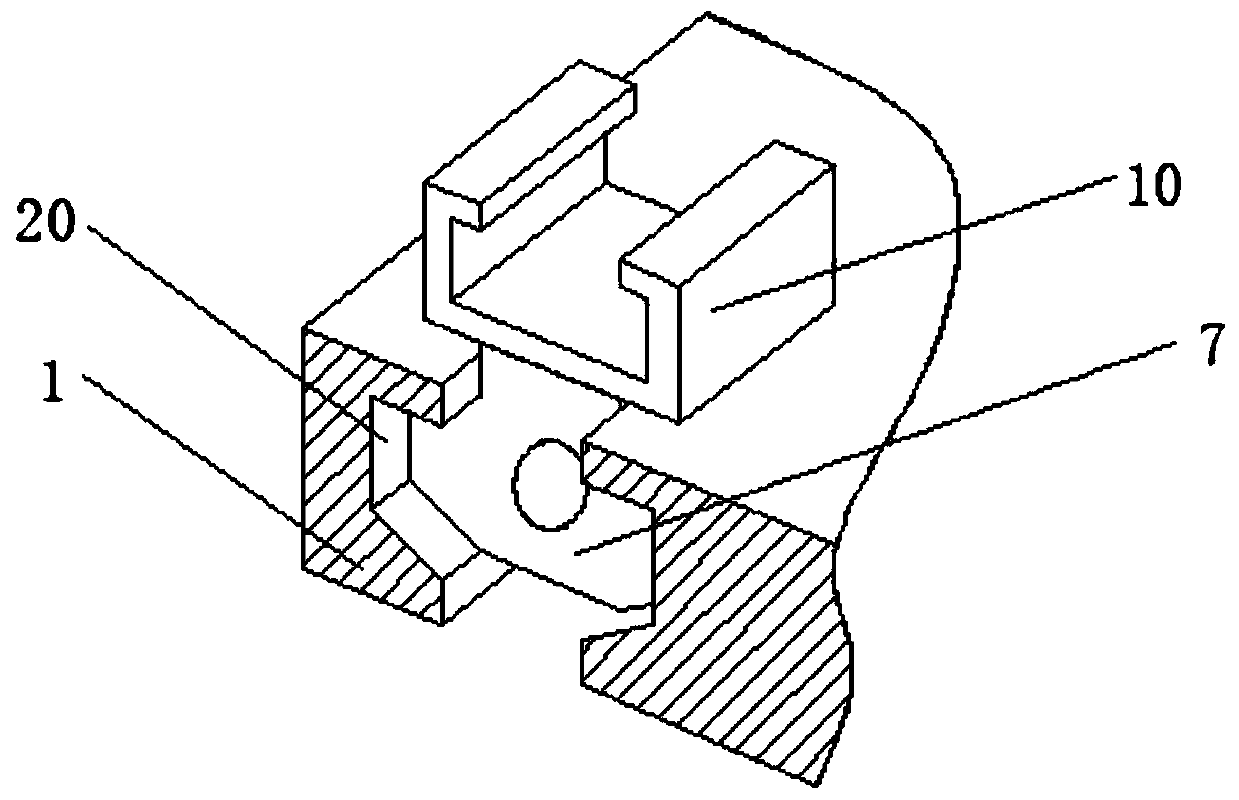

[0028] refer to Figure 1-4 , a positioning mechanism for electromechanical equipment processing, including a mounting frame 1, a plurality of strip-shaped holes 20 are provided on both sides of the top of the mounting frame 1, and two rectangular through slots 3 are provided in the middle of the top of the mounting frame 1. The inside of the hole 20 is rotatably connected with a threaded rod 6 through a bearing, and the outer side of the threaded rod 6 is screwed with a movable block 7, the top of the movable block 7 is provided with a socket 10, and the inside of the socket 10 is plugged with a support frame 11. Both sides of the installation frame 1 are connected with a servo motor 9 corresponding to the strip hole 20 through bolts, and the output shaft of the servo motor 9 is connected with the threaded rod 6 through bolts, and the side of the support frame 11 is connected with a bolt. Telescopic cylinder 12, the top of support frame 11 is hinged with connecting rod 14, an...

Embodiment 2

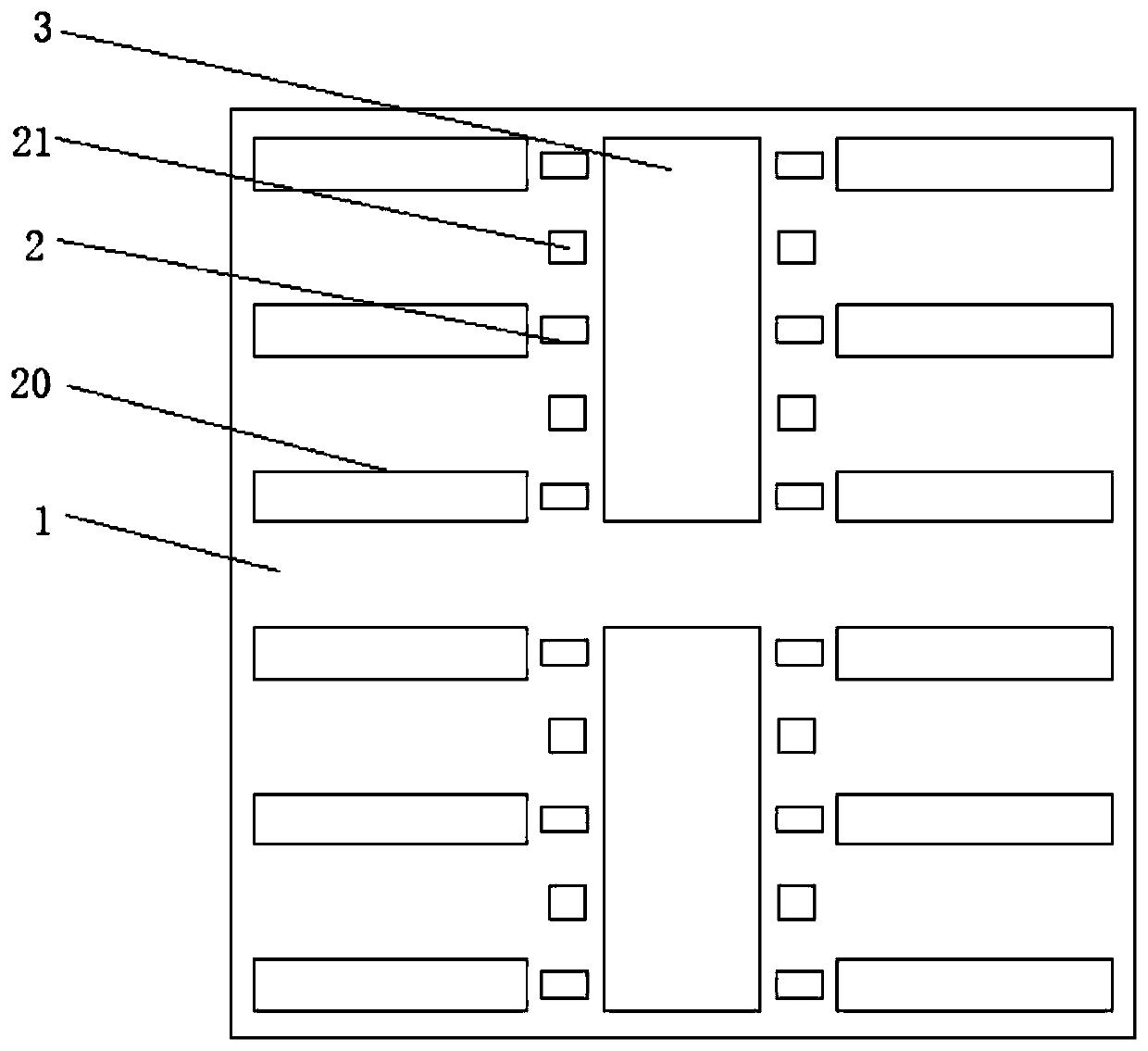

[0035] refer to Figure 1-5, a positioning mechanism for electromechanical equipment processing, the bearing mechanism includes a bearing part 17 and an insertion part 5, and the bearing part 17 and the insertion part 5 are integrally formed, and the insertion part 5 is a square prism structure;

[0036] The top of the mounting frame 1 is provided with a plurality of rectangular holes 21, and the bottom end of the insertion part 5 is inserted into the interior of the rectangular holes 21;

[0037] Both the inner wall of the rectangular through groove 3 and the side of the insertion part 5 are provided with threaded grooves, and the interior of the threaded grooves is screwed with a positioning bolt 4 .

[0038] In this embodiment, the bearing mechanism can be disassembled through the socket 5 and the rectangular hole 21, and different bearing mechanisms and clamping bodies 16 can be replaced according to the shape of the workpiece, and then the positioning mechanism can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com