Clamping component structure of industrial robot

An industrial robot, one-to-one corresponding technology, applied in the directions of chucks, manipulators, manufacturing tools, etc., can solve the problems of the object being clamped, such as vibration, and achieve the effect of firm clamping, easy unified control, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

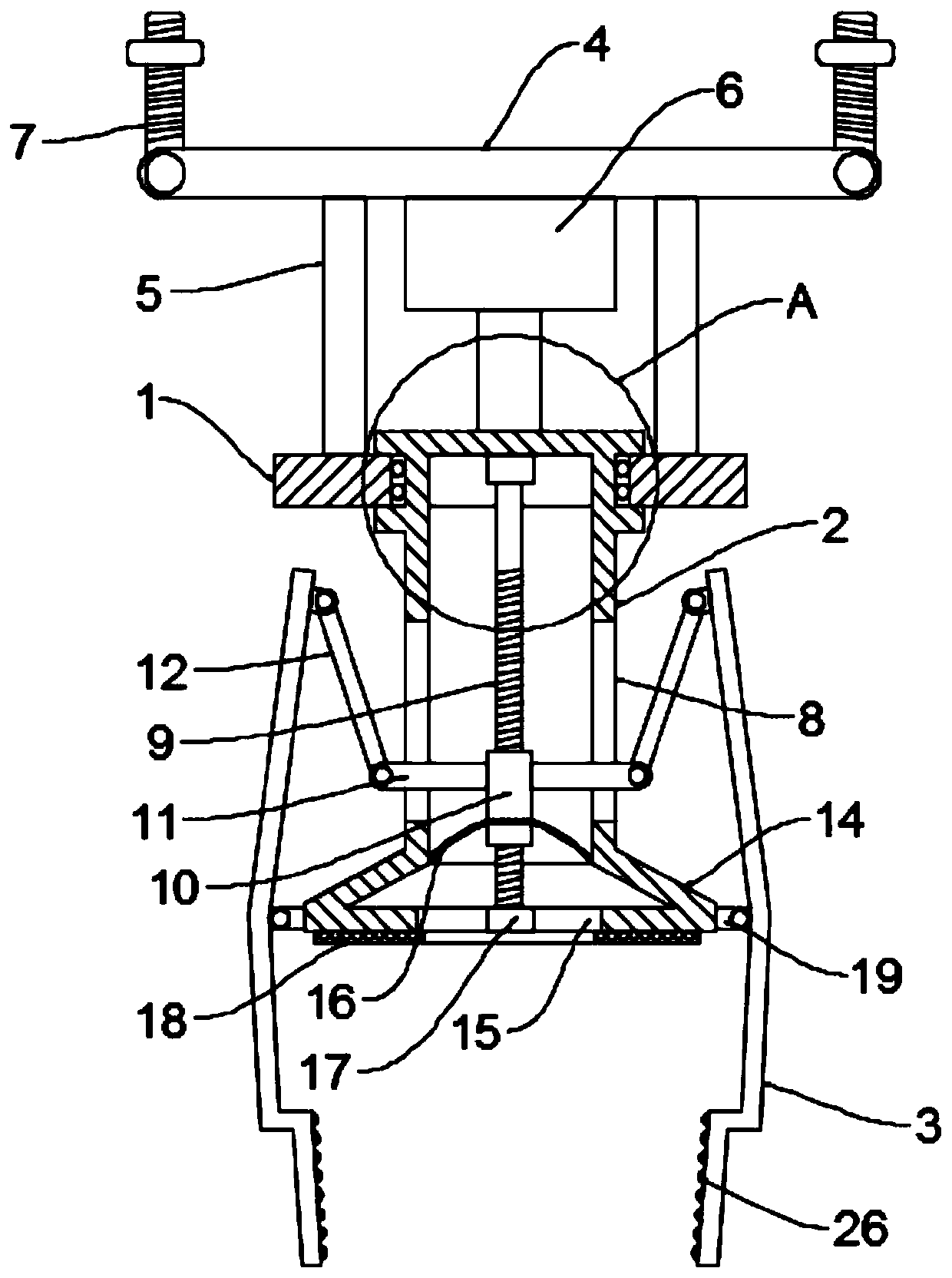

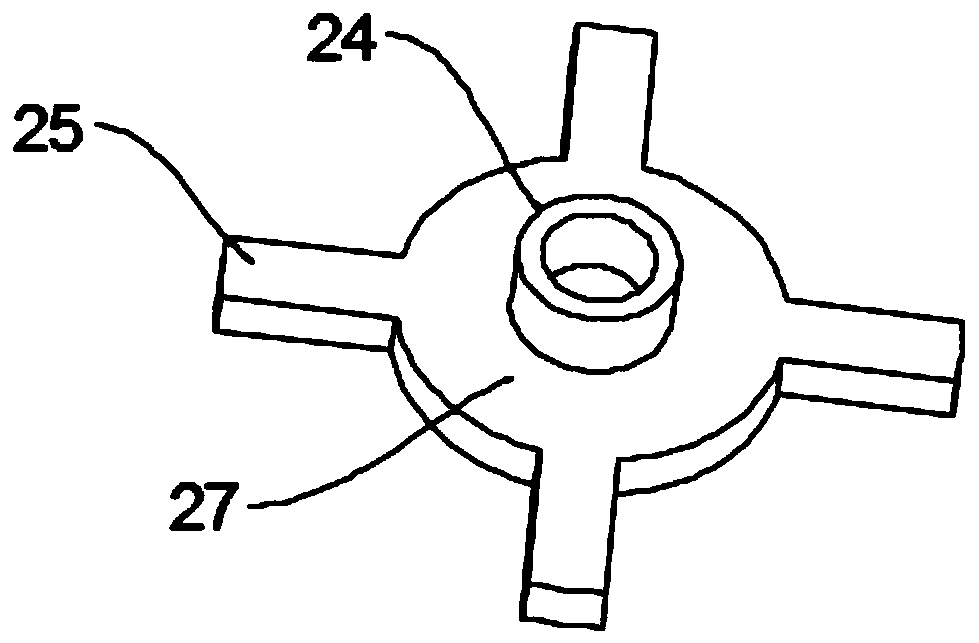

[0024] see Figure 1~3 , in an embodiment of the present invention, a clamping part structure of an industrial robot includes a fixed mounting plate 1, a fixed cylinder 2 mounted on the fixed mounting plate 1, and a plurality of clamping rods arranged on the outer wall of the fixed cylinder 2 Part 3, the bottom of the fixed cylinder 2 is provided with a suction cup body 14 in a cone structure and communicated with it, and the side wall of the suction cup body 14 is fixed with a hinge seat 19 corresponding to the clamping rod 3 one by one , the middle part of the clamping rod 3 is hinged on the corresponding hinge seat 19, the inside of the fixed cylinder 2 is provided with a pushing assembly that can toggle the clamping rod 3, and the pushing assembly includes a rotating set inside the fixed cylinder 2 Drive screw mandrel 9, the top of drive screw mandrel 9 is connected with the output shaft of electric control clamping motor 20 fixed on the top wall of fixed cylinder body 2, ...

Embodiment 2

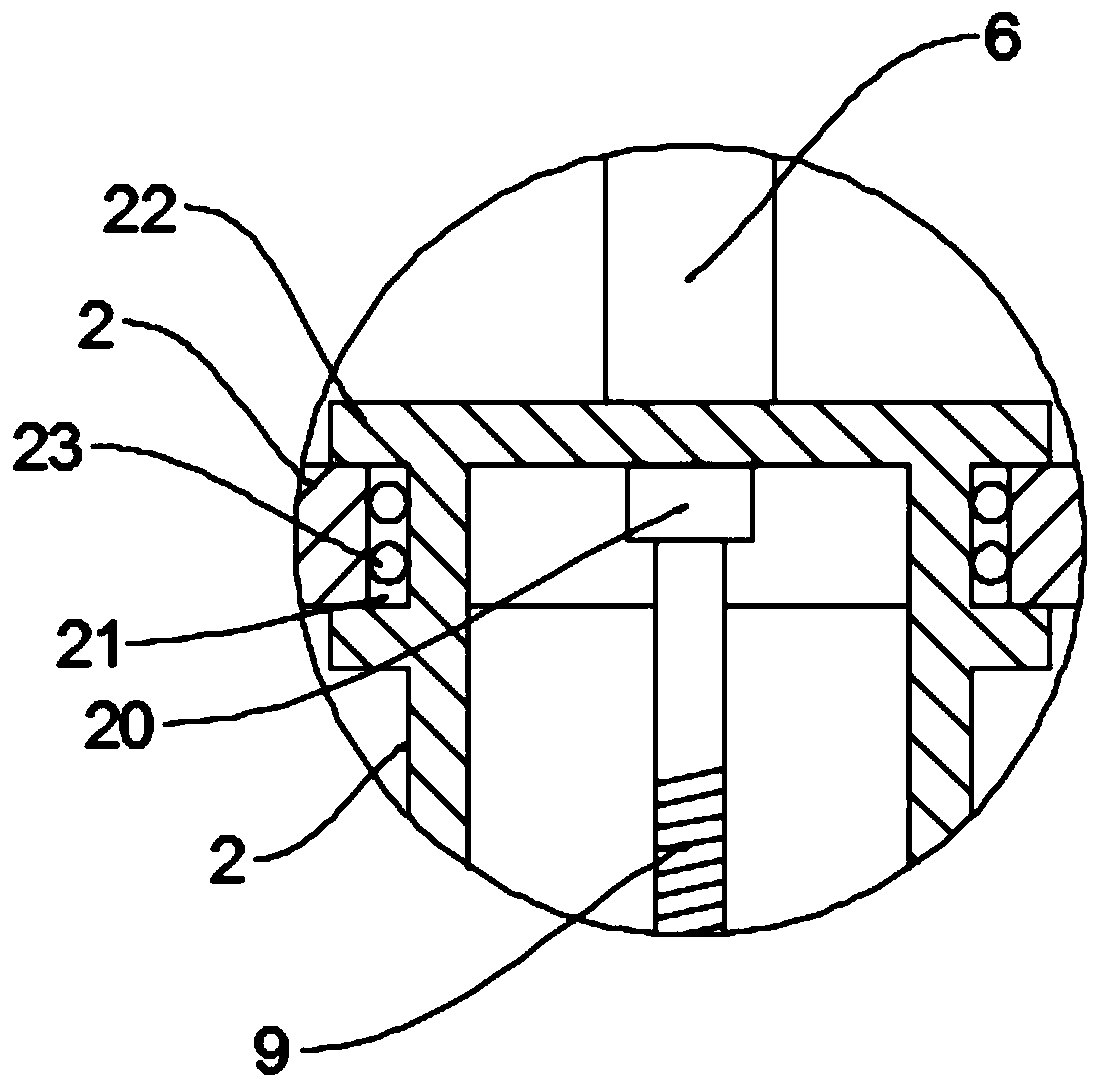

[0029] The difference between the embodiment of the present invention and embodiment 1 is that the fixed cylinder 2 is rotatably connected to the fixed installation plate 1, specifically, the middle part of the fixed cylinder 2 is provided with an installation through hole 21, and the fixed cylinder 2 2 pass through the installation through hole 21 and connect with the inner wall of the installation through hole 21 through the bearing 23, the outer wall of the top of the fixed cylinder 2 is provided with flanges 22 placed on both sides of the fixed cylinder 2 and the outer diameter of the flange 22 is larger than the installation The inner diameter of the through hole 21 prevents the fixed cylinder 2 from falling from the fixed mounting plate 1. An electric control rotary motor 6 is arranged on the top wall of the connecting plate 4, and the bottom end of the output shaft of the electric control rotary motor 6 is connected to the fixed The top of the cylinder body 2, driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com