Height-adjustable casting mold machining clamping mechanism

A technology for casting molds and clamping mechanisms, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc., can solve problems such as unfavorable promotion and use, increase resource consumption, and increase use costs, so as to save resources and save Resource, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

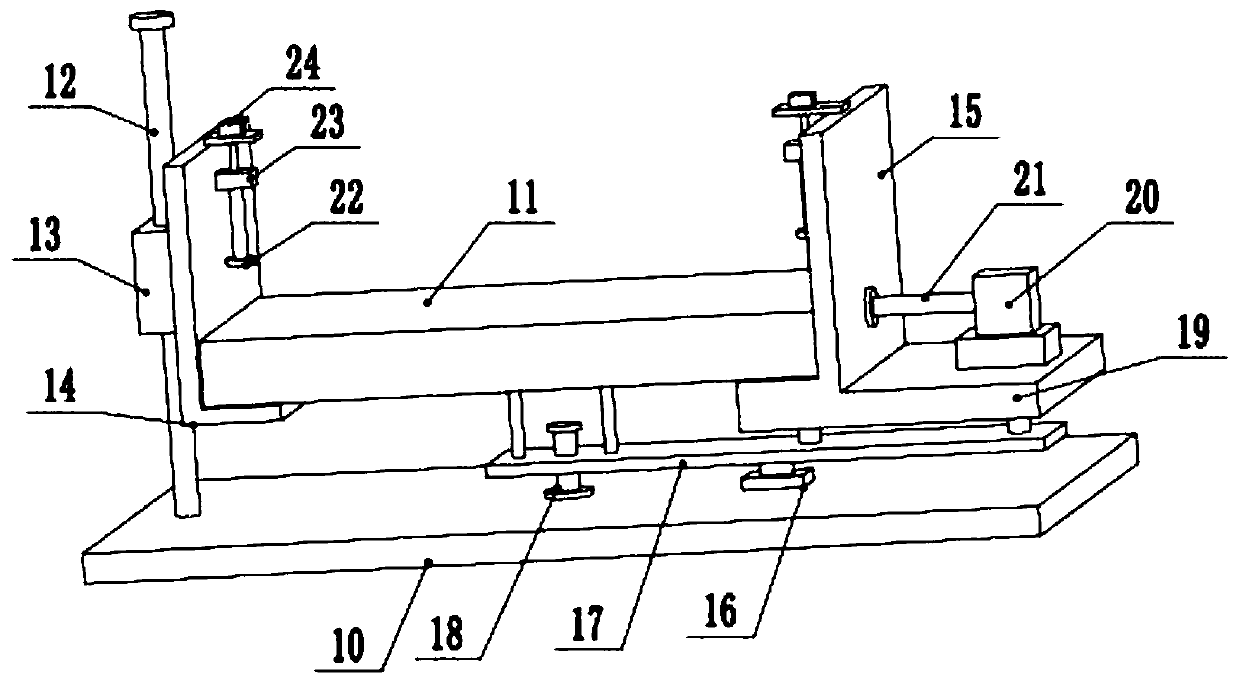

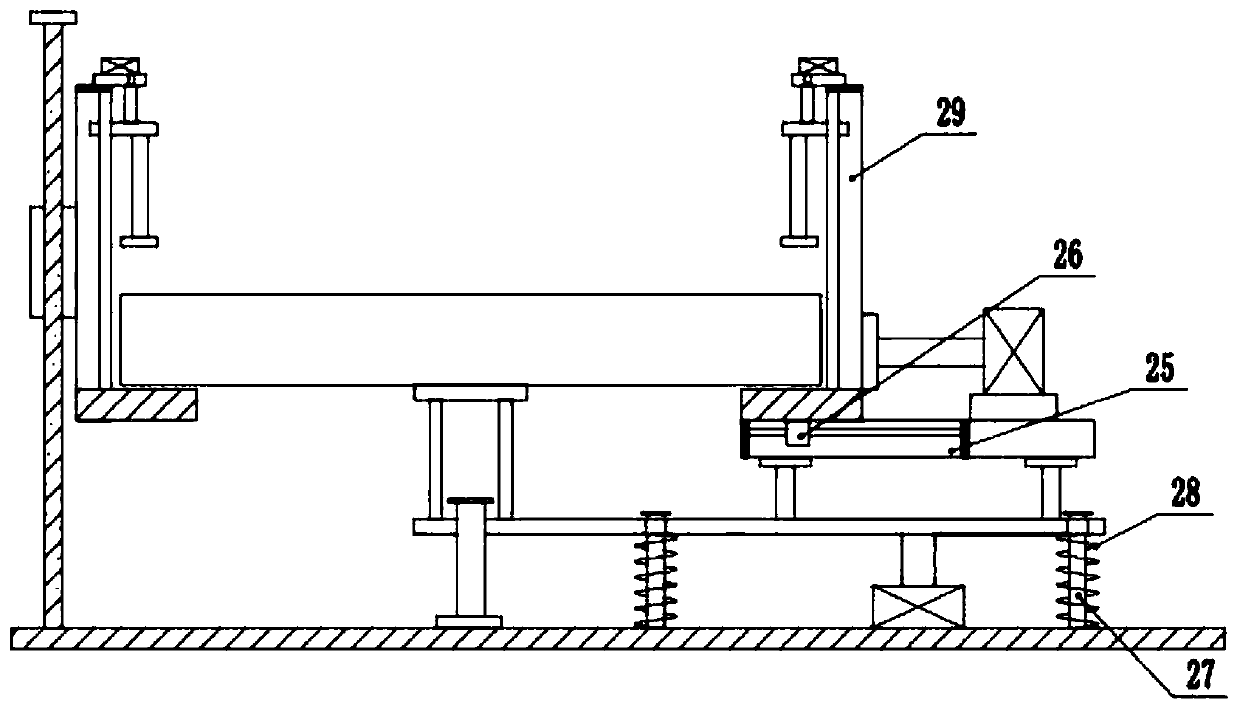

[0021] see Figure 1-2 , a height-adjustable clamping mechanism for casting mold processing, including a base plate 10, a fixed support plate 14, and a movable support plate 15; There is a sliding sleeve 13, the top of the sliding rod 12 is fixedly installed with a limit plate to prevent the sliding sleeve 13 from falling off, and the right side of the sliding sleeve 13 is fixedly installed with a fixed supporting plate 14 in an L-shaped structure, which is located on the right side of the fixed supporting plate 14 A group of movable pallets 15 symmetrical to the fixed pallet 14 are arranged above the bottom plate 10, and the casting mold 11 to be clamped is placed between the two through the supporting effect of the fixed pallet 14 and the movable pallet 15. . The inner and outer surfaces of the fixed pallet 14 and the movable pallet 15 are all laid with a rubber pad for preventing abrasion of the outer surface of the casting mold 11 . The tops of the fixed supporting plate...

Embodiment 2

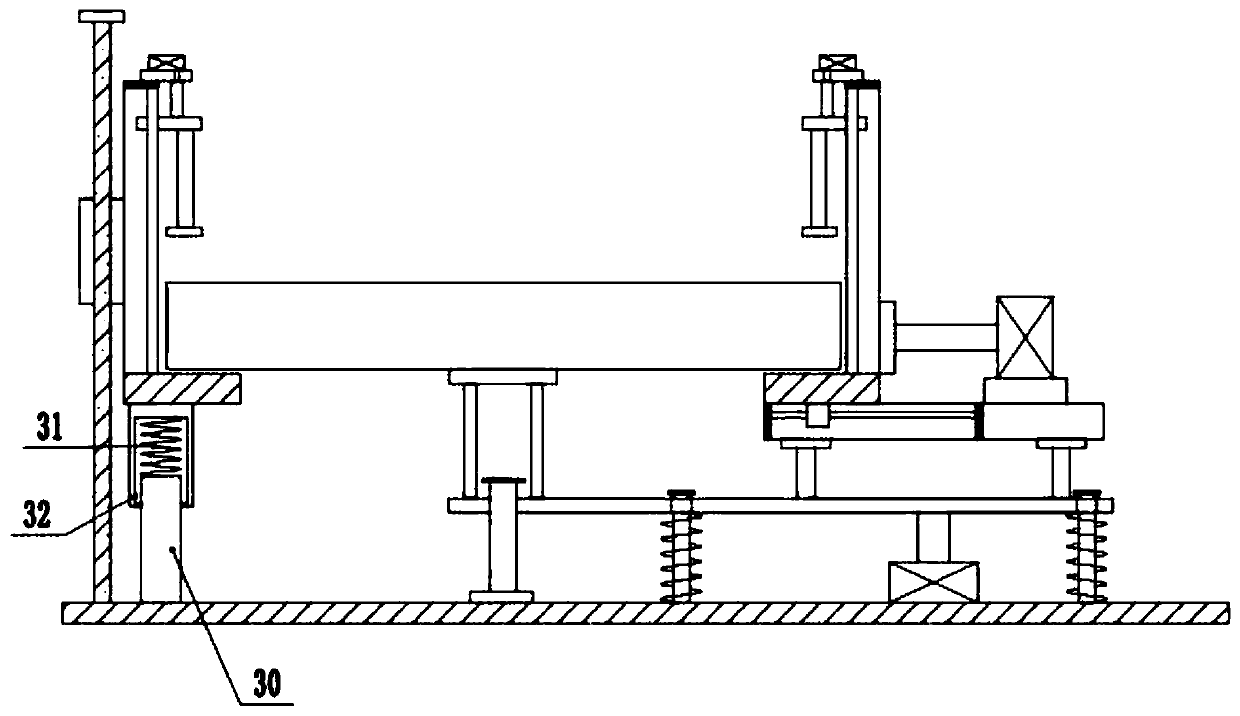

[0026] refer to image 3 , on the basis of Embodiment 1, a group of buffer frames 31 with lower side openings are fixedly installed on the lower surface of the bottom of the fixed pallet 14, and a group of pillars 30 with bottoms fixed on the upper surface of the bottom plate 10 are arranged inside the buffer frame 31, and the pillars The top of 30 is elastically connected by spring 28 before the inner top of buffer frame 31. By setting pillar 30 and buffer frame 31 at the bottom of fixed pallet 14, it is used to slow down fixed pallet 14 when it is stationary or moves up and down. The fixed pallet 14 and the casting mold 11 on the upper side of the fixed pallet 14 exert downward gravity on the right movable pallet 15, thereby further improving the force balance between the left and right groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com