Windshield wiper

A wiper and wiper technology, applied in the field of auto parts, can solve problems such as insufficient lateral rigidity of wipers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

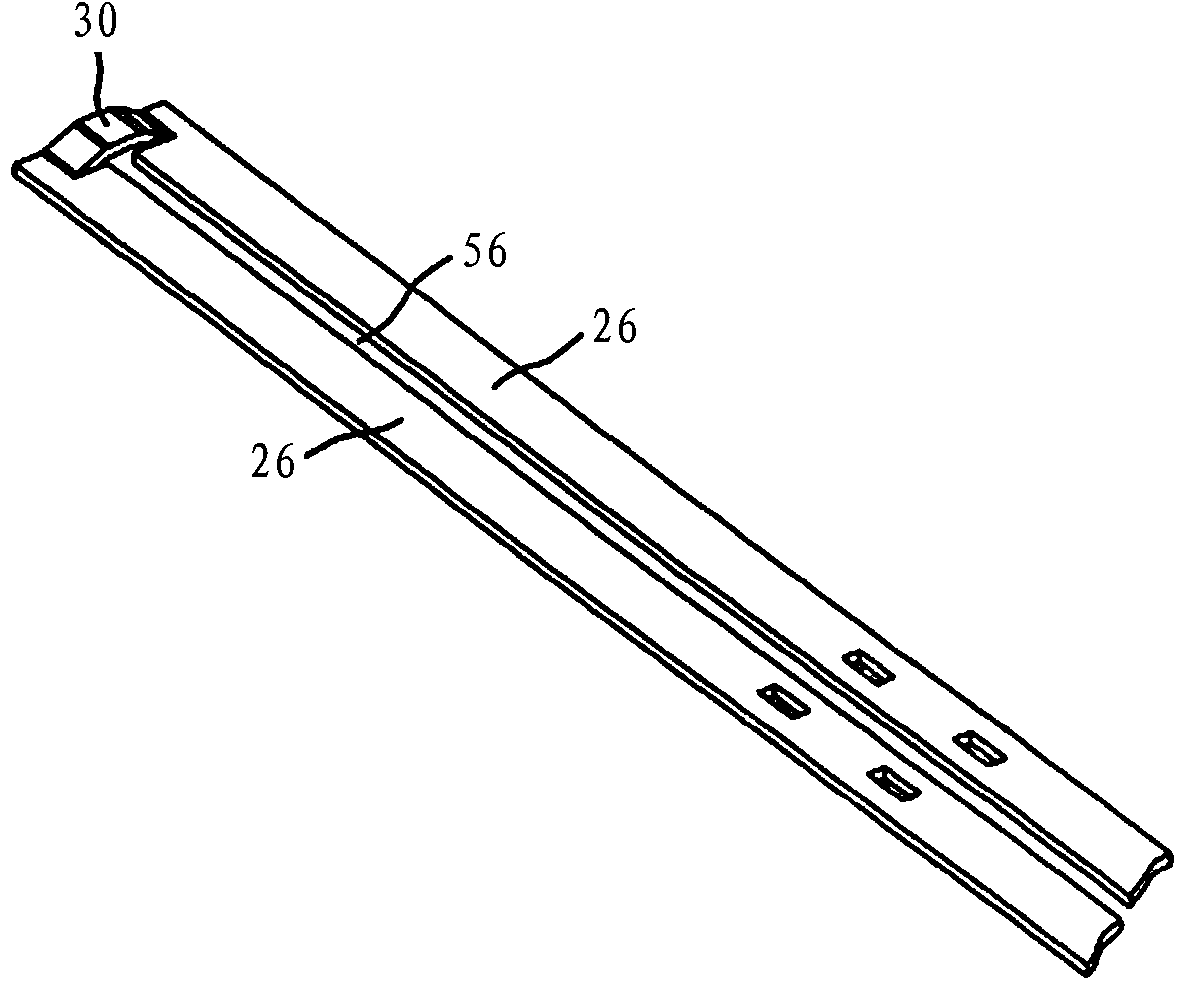

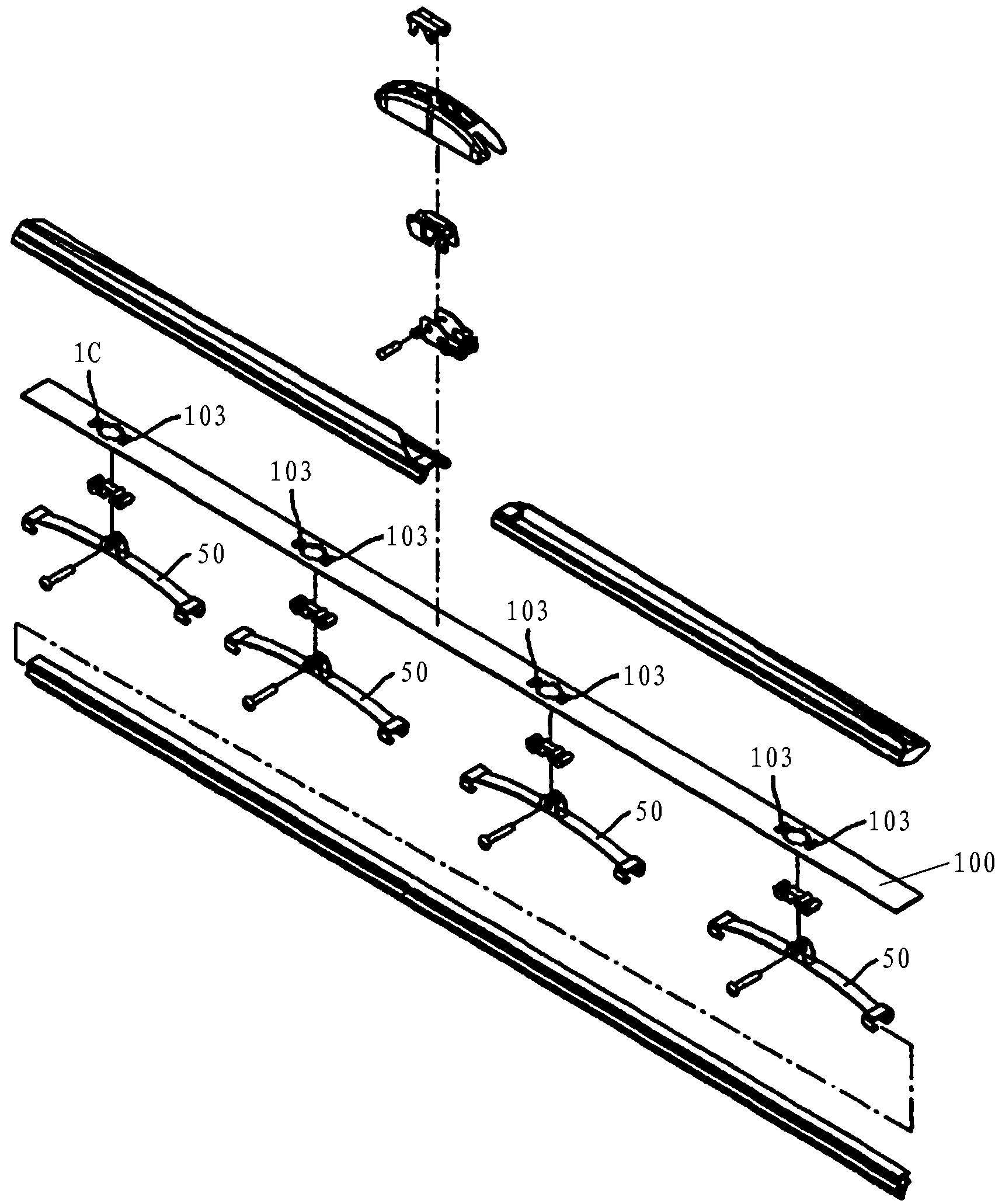

[0023] Such as image 3 , Figure 4 As shown, the present invention is a wiper, which includes a wiper elastic support part 1, a wiper blade 2, a connecting seat 3, a clip 4, and a wiper deflector 5.

[0024] A plurality of T-shaped slots 11 are arranged equidistantly and at intervals along the length direction of the wiper elastic support member 1. The T-shaped slots 11 are provided with a large diameter end 111 and a small diameter end 112, and the wiper elastic support member 1 has a certain curvature. , in order to realize the pre-tightening force on the wiper strip 2.

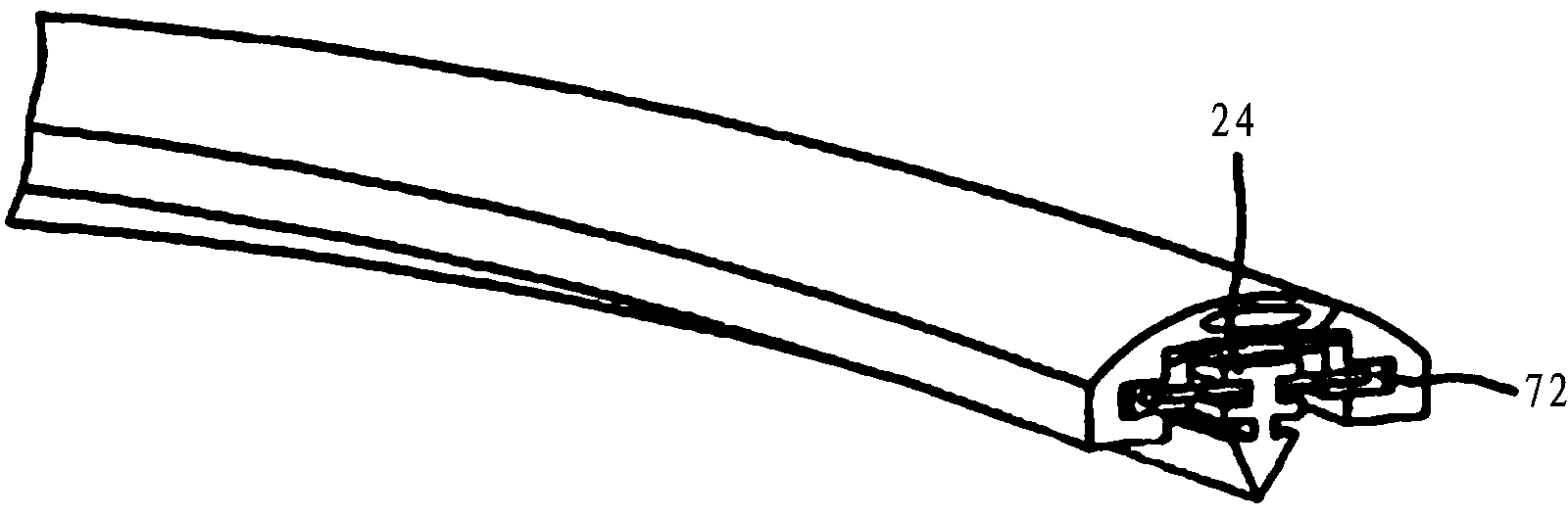

[0025] to combine Figure 7-1 As shown, the wiper strip 2 is composed of a connecting portion 21 and a wiper portion 22, and the connecting portion 21 is composed of a plurality of upwardly protruding T-shaped buckles 211, and the plurality of T-shaped buckles 211 etc. The distance and interval are fixed on the top surface of the wiper part 22, and the distance between the multiple T-shaped buckles 211 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com