Assembled truss formwork anti-sideshift support

An assembled, side-shifting-resistant technology, which is applied in the field of formwork/formwork/work frame, preparation of building components on site, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

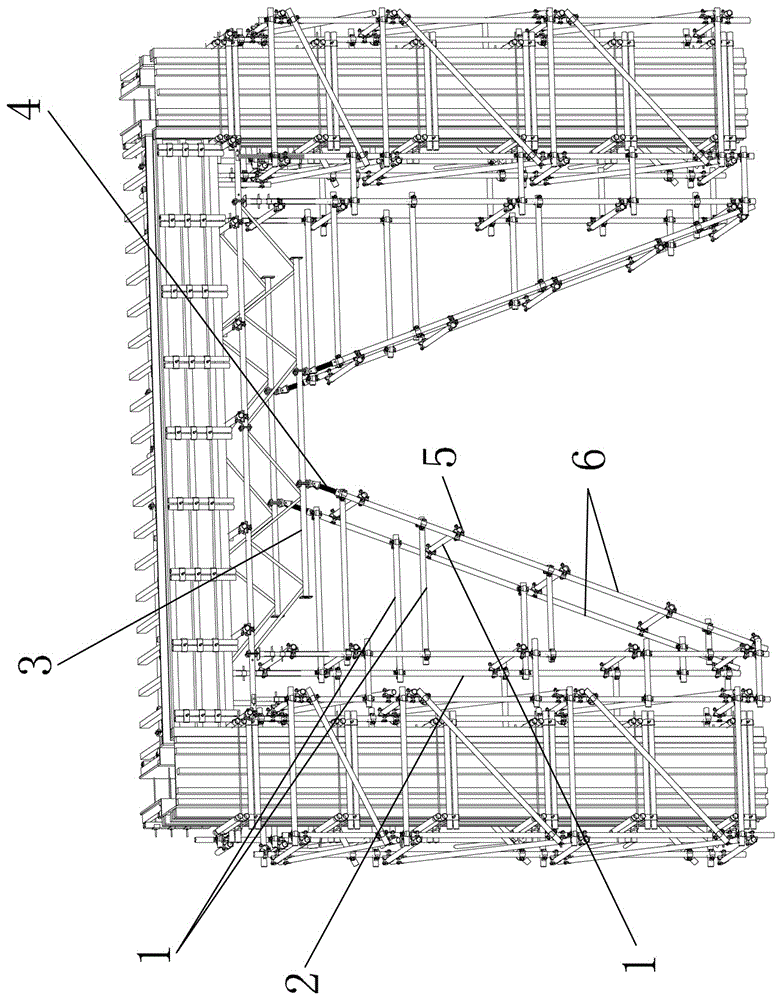

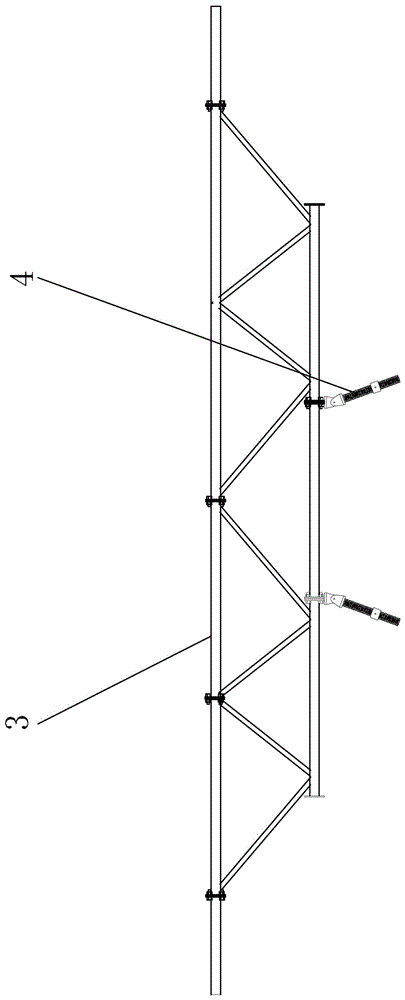

[0013] As shown in the figure: add a universal connecting rod 4 at the lower chord node of the assembled truss 3 in the direction of the secondary beam, and connect it with bolts. The oblique support 6 of the universal connecting rod 4 is provided with a horizontal rod 1 and a vertical support through fasteners 5 2 connection, the oblique support 6 between the two trusses is connected by adding a horizontal rod 1 through the fastener 5 to form a space portal support to increase the lateral stiffness against lateral movement.

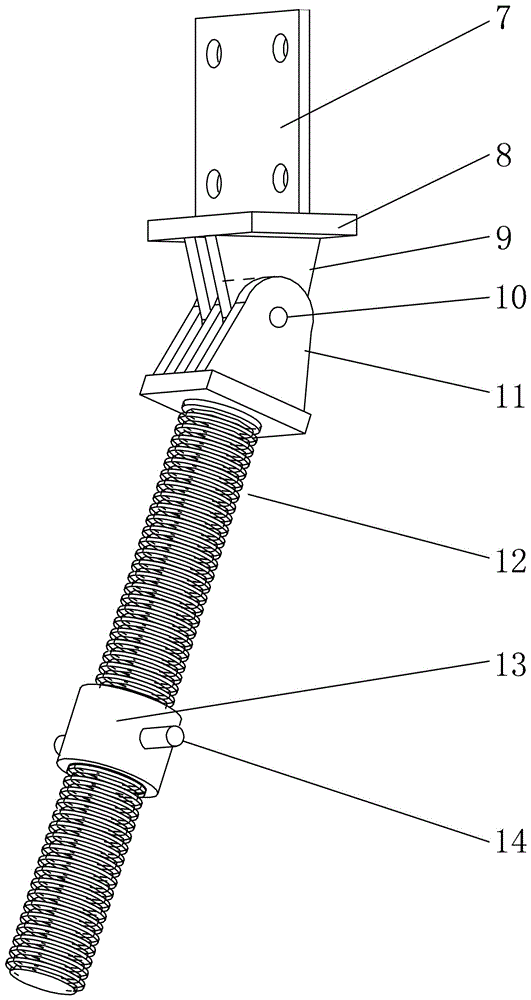

[0014] The structure of the universal connecting rod 4 is that the upper bottom plate 8 is welded under the vertical connecting plate 7, the upper connecting plate 9 of the pin shaft is welded under the upper bottom plate 8, and the upper part of the lower bottom plate is welded and connected with the supporting pin shaft of the upper connecting plate of the pin shaft. Plate 11, upper and lower pin shaft connection plate punches and penetrates pin shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com