Tunnel lining steel belt reinforcing structure and construction method

A technology for strengthening structures and construction methods, applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of inconvenient construction, unreliable reinforcement, and high cost, and achieve the effects of fast construction, reliable tunnel lining structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

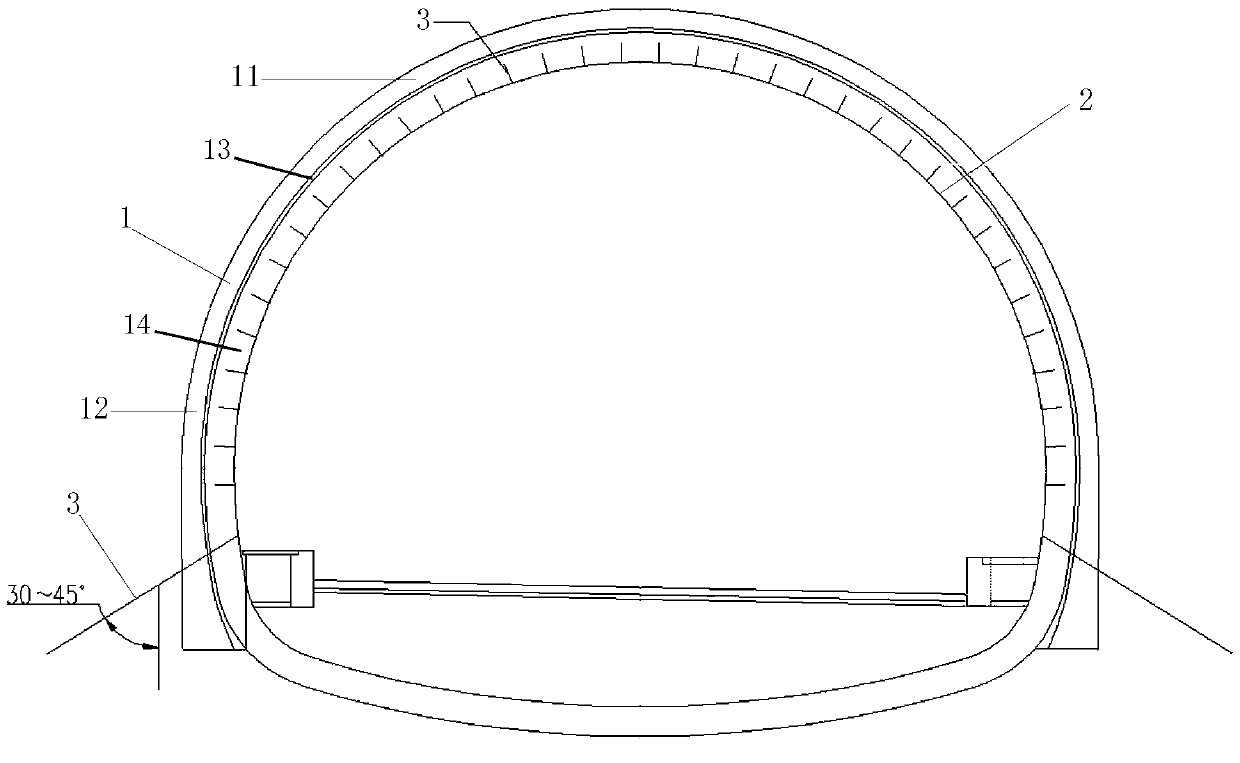

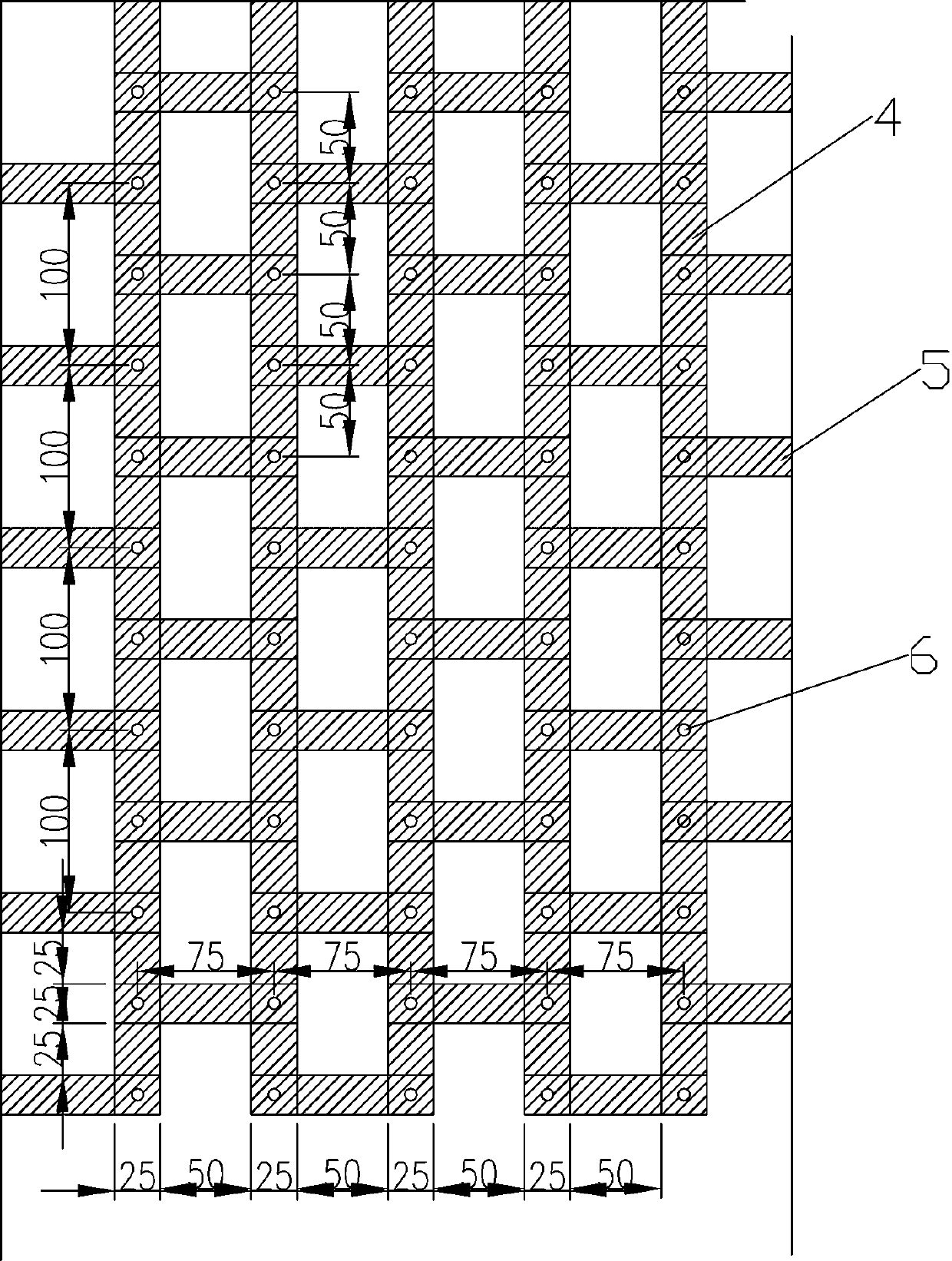

[0037] Embodiment 1: A kind of tunnel lining steel strip reinforcement structure, see figure 1 , including steel belt 2 and lock foot anchor 3, the lining includes primary support structure 1, vault 11, side walls 12 on both sides, waterproof and drainage structure 13 and secondary lining structure 14, steel belt 2 includes hoop steel belt 4 and longitudinal Steel belt 5.

[0038] The hoop steel belt 4 is spliced by a plurality of 25cm wide and 5mm thick Q235B-type segmented steel belts. The joints at the segments are welded with flat openings, and then lapped with 70cm long joint steel plates. The joint steel plates and The original reinforced steel plates are fixed with M16×160 bonding mold bottom expansion anchor bolts, and bonded with steel glue.

[0039] The hoop steel belt 4 adapts to the cross-sectional shape of the lining and extends from one side wall to the other side wall. A plurality of hoop steel belts 4 are arranged intermittently along the tunnel longitudinal...

Embodiment 2

[0042] Embodiment 2: A construction method of the tunnel lining steel strip reinforcement structure of Embodiment 1, comprising the following steps:

[0043] (1) Measurement positioning

[0044] Carry out measurement and setting-out positioning. In order to ensure that the steel strips are installed on one line, the positioning should be carried out according to the construction joints of the lining or formwork joints when marking the line, and the position of each steel strip should be marked with an ink line.

[0045] (2) Base surface treatment, concrete surface cleaning

[0046] Remove the fireproof coating and corroded concrete on the surface of the concrete where the steel belt is attached, and grind the surface dust to 2-3mm, so that the lining concrete is completely exposed to the fresh surface, and blow off the dust with compressed air, clean the concrete surface and keep it dry. The base surface should be smooth and smooth, with the flatness not greater than 1.5mm / m,...

Embodiment 3

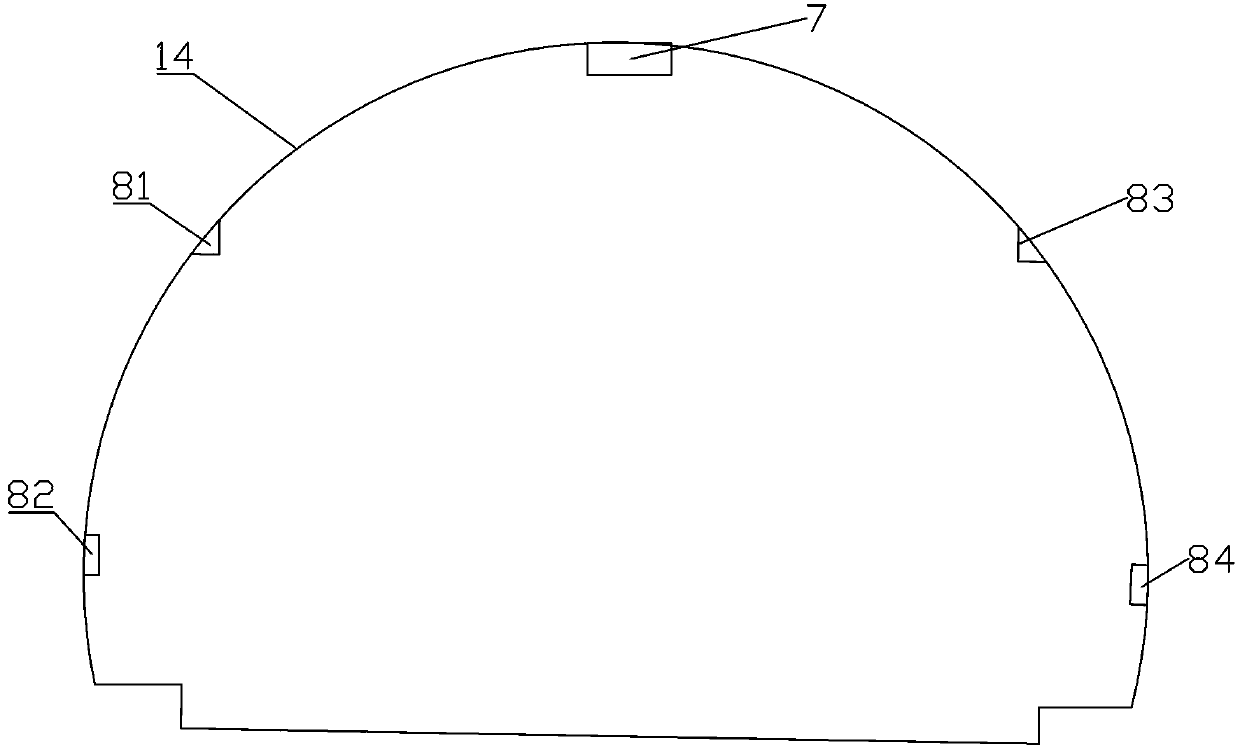

[0059] Example 3: During the installation and reinforcement of the steel belt 2 in Example 2, it is necessary to measure the surrounding rock and support (the original structural surface), and the required items include: observation of structural disease, peripheral displacement, vault sink. The observation of structural damage should start from the following two aspects: the observation of the increase of cracks; the observation of the development of cracks and staggered platforms and the development of groundwater. During the observation process, the width, length, date and other on-site markings should be done well.

[0060] The measurement method and layout shall be carried out in accordance with the "Technical Specifications for Construction of Highway Tunnels" (JTGF60-2009). The measurement method adopts the free station non-contact method of the total station. The vault sinking measurement point is buried at the center line of the vault tunnel, and two sets of peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com