Fast cage type tobacco clamp for bulk curing barn

A dense barn and fast technology, applied in the field of clamping tools, can solve the problems of manual pole weaving, such as labor-intensive, undurable, and insignificant reduction effects, and achieve the expansion of planting scale and factoryization, increase of strength and natural recovery , The effect of reducing labor and technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

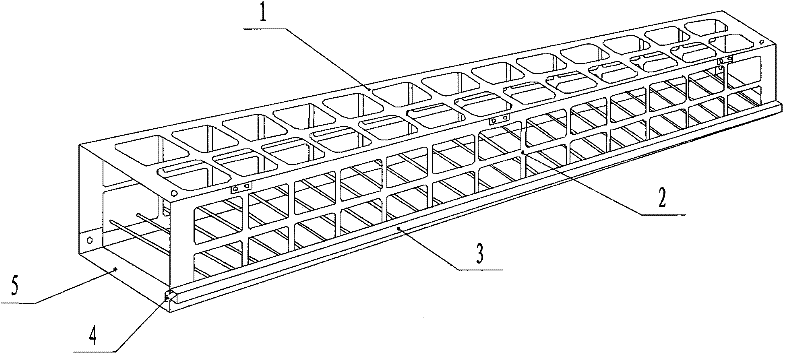

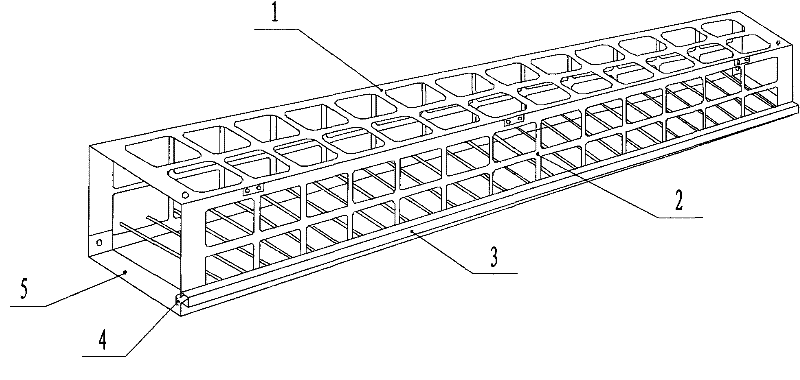

[0013] like figure 1 As shown, the present invention includes: an L-shaped bracket 1 , a movable cover 2 , a cigarette fork 3 , a clip 4 , and a support frame 5 .

[0014] Support frame 5 is equipped with at both ends of L-shaped support 1, movable cover 2 is connected with L-shaped support 1 by hinge so that it can rotate, and movable cover 2 closes on support frame 5 after being closed, and L-shaped support 1 and movable cover 2. Several holes with flanges are arranged on the surface, and the holes are square or other shapes. Insert the comb-type cigarette fork 3 so that the pins are placed on the lower edge of the L-shaped bracket 1 and the movable cover 2 holes, and then use the elastic buckle 4 to clamp the cigarette fork 3 together with the movable cover 2 on the support frame 5 .

[0015] When in use, put the L-shaped support 1 togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com