Integral type rolling machine axial adjusting device

An axial adjustment and integrated technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of large matching clearance of positioning bolts to adjust the pressure plate, difficult operation, and deformation of the roll head. , to achieve the effect of firm fixed roll bearing seat, easy adjustment and operation, and enhanced fixing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Here, for convenience of description, a three-high section mill will be described as an example, and the same reference numerals will be used for the same parts in the drawings.

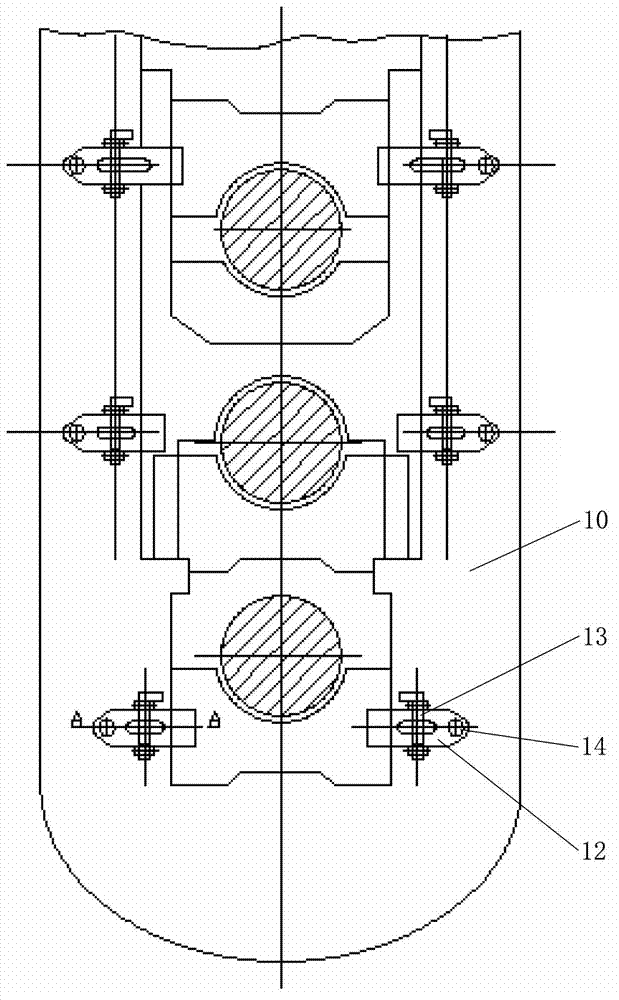

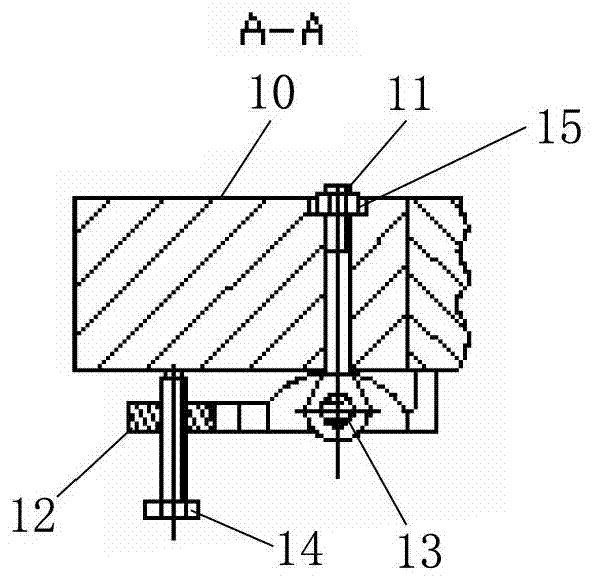

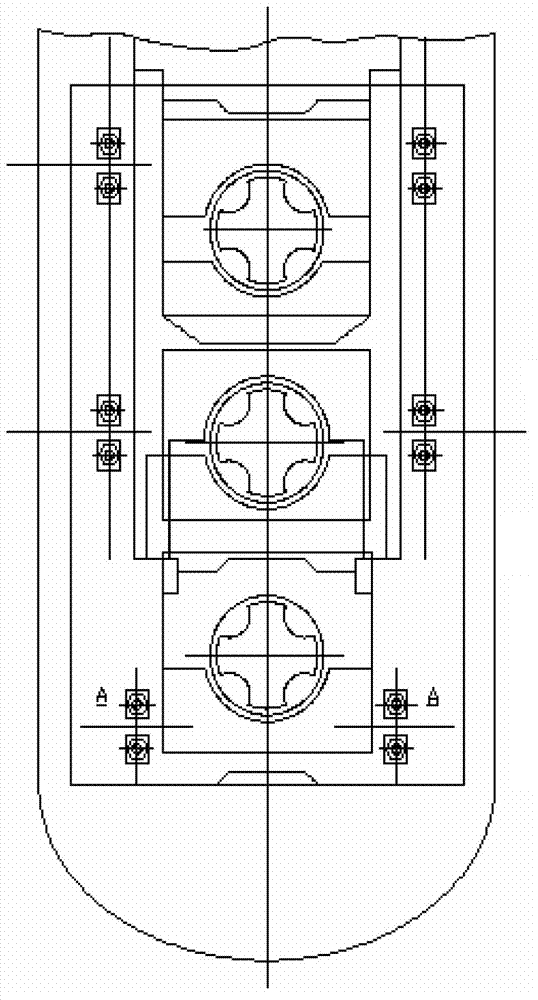

[0019] image 3 It shows the integral rolling mill axial adjustment device of the three-roll section steel rolling mill of the present invention. Figure 4 express image 3 The A-A line profile.

[0020] Such as image 3 and Figure 4 As shown, the integral rolling mill axial adjustment device of the present invention includes a rolling mill column 1, a roll chock 3 arranged on the rolling mill column 1 and used to support the roll 2, and a semicircular head inserted into the through hole 5 of the rolling mill column 1 Bolt 4, integral axial pressure plate 6 for fixing and adjusting roll chock 3.

[0021] Wherein, three openings are provided on the integral axial pressure plate 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com