Sliding track device

A technology of slide rails and sliders, applied in the direction of bearings, linear motion bearings, shafts and bearings, etc., can solve the problems of inconvenient production and assembly, complex structure, etc., and achieve the effect of reasonable structure, smooth movement and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

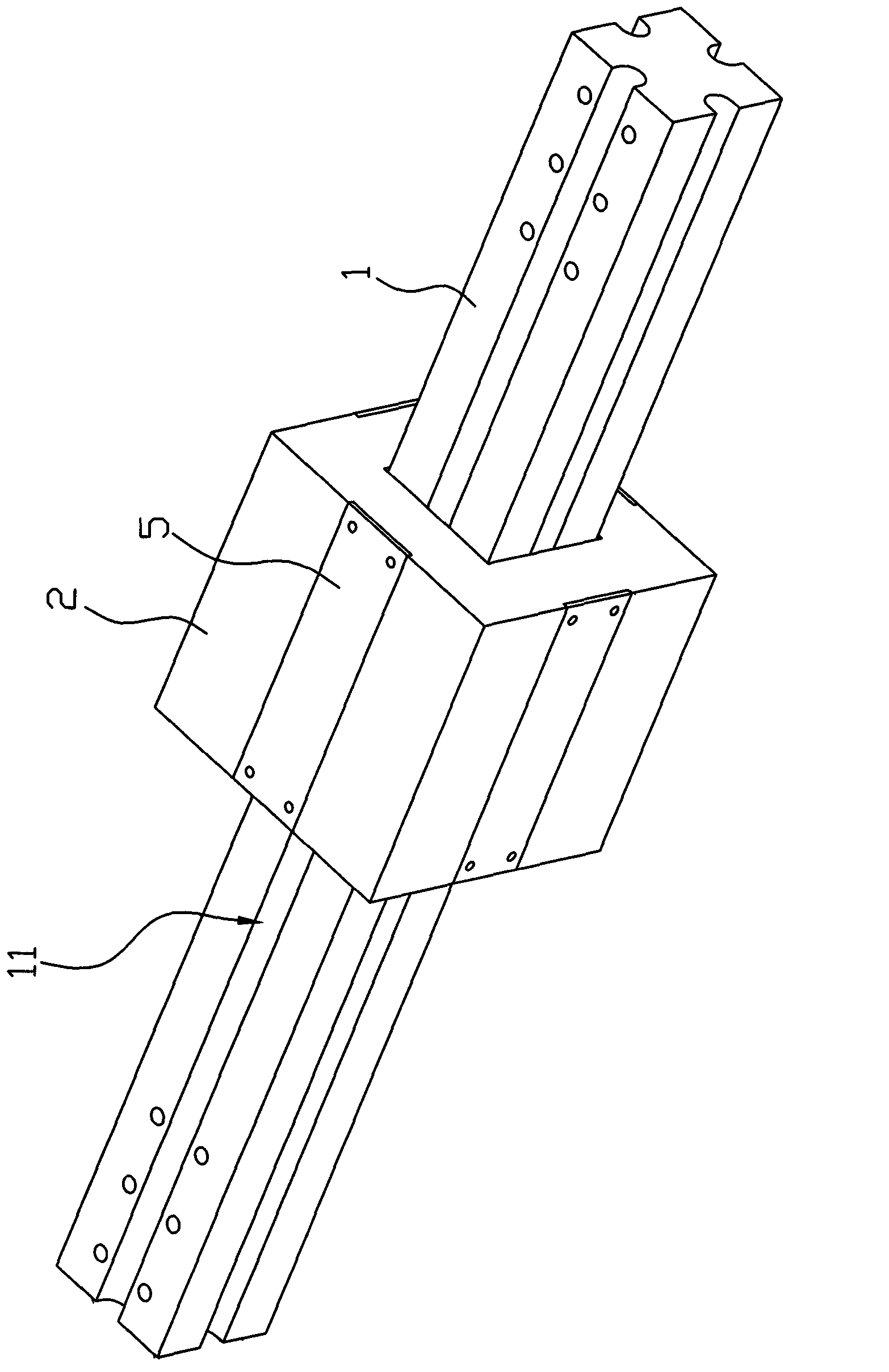

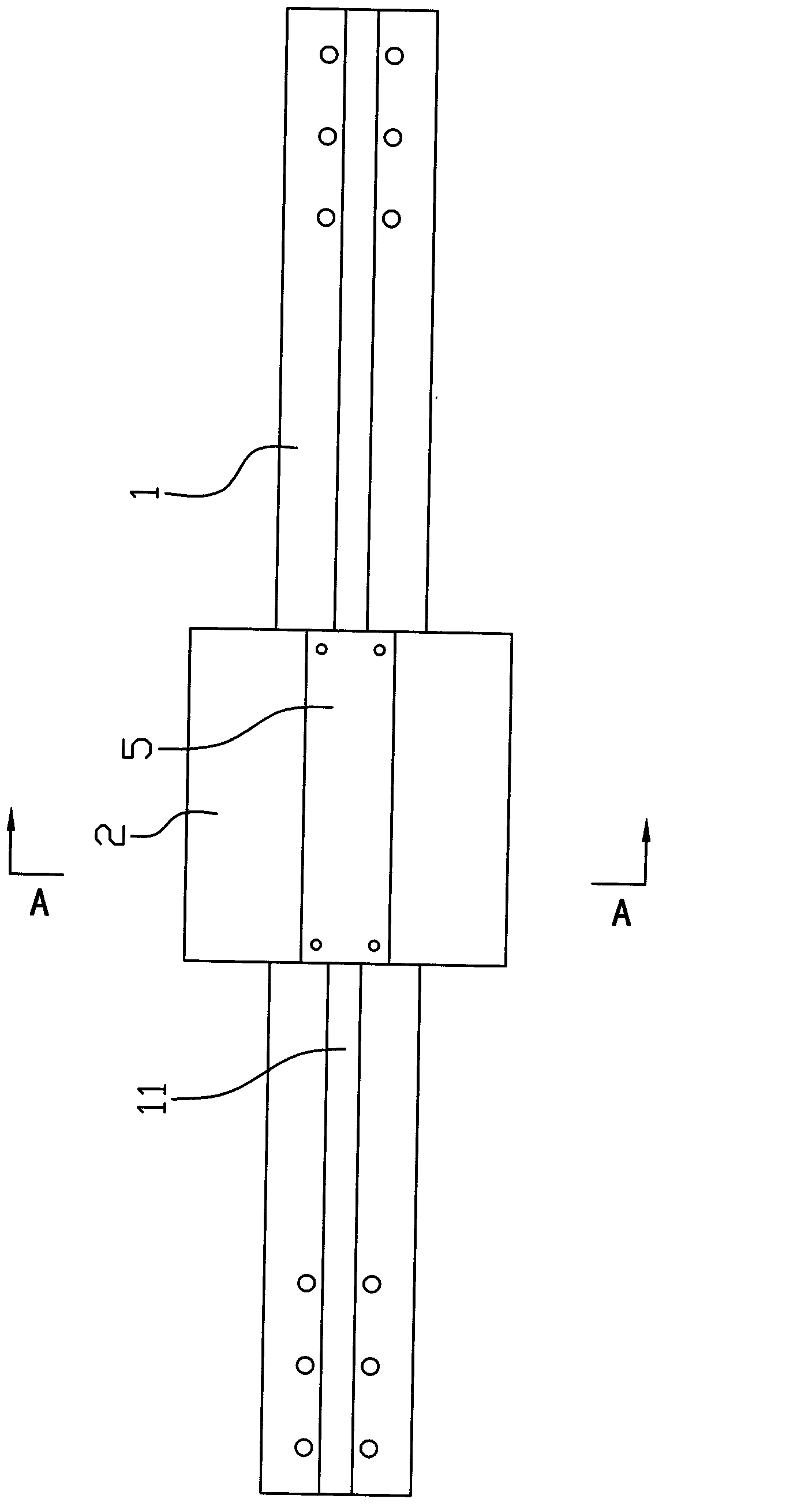

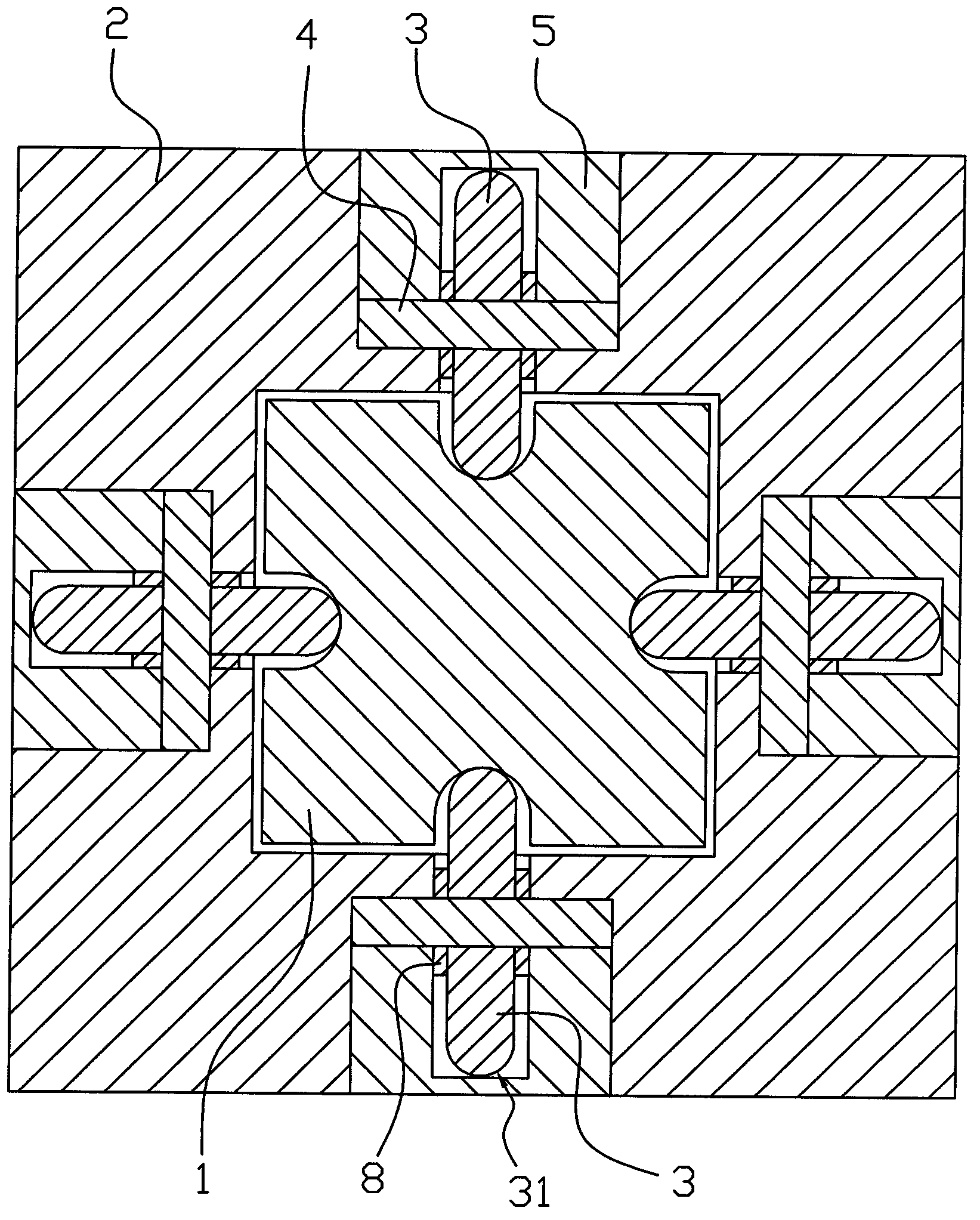

[0020] Example one, such as Figure 1 to Figure 4 As shown in the slide rail device of this embodiment, the sliding block 2 can be slidably placed on a matching guide rail 1. The guide rail 1 is a rectangular strip, and the middle of the four sides of the rectangular strip is provided with axial recesses. The two ends of the sliding groove 11 pass through, the orthographic projection of the end surface of the guide rail 1 is a rectangle with notches in the middle of the four sides, and the sliding block 2 is axially provided with a rectangular cavity 21 that penetrates through the two ends and is adapted to the rectangular strip. , And the four inner walls of the rectangular cavity 21 are respectively provided with rollers 3: the slider 2 is provided with a roller groove 22 and a shaft seat groove 23 on the four sides, and the roller 3 extends into the rectangular cavity 21 and corresponds to the sliding groove 11 can be fitted together in a rolling manner, and the roller 3 is e...

Embodiment 2

[0021] Example two, such as Figure 5 to Figure 8 As shown, the slide rail device of this embodiment is similar in structure to the above device. The specific structure of the roller 3 protruding on the inner wall of the rectangular cavity 21 is: the sliding block 2 is provided with module cavities 24 on all four sides, respectively. A suitable module 6 is inserted in the module cavity 24, and the roller 3 is rotatably arranged in the module 6. When the module 6 is inserted in the module cavity 24 of the slider 2, the roller 3 extends The inner wall of the rectangular cavity 21 and the corresponding sliding groove 11 can be fitted together in a rolling manner. The module 6 is fixed to the sliding block by a fastener 7. The fastener 7 may be a screw or a bolt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com