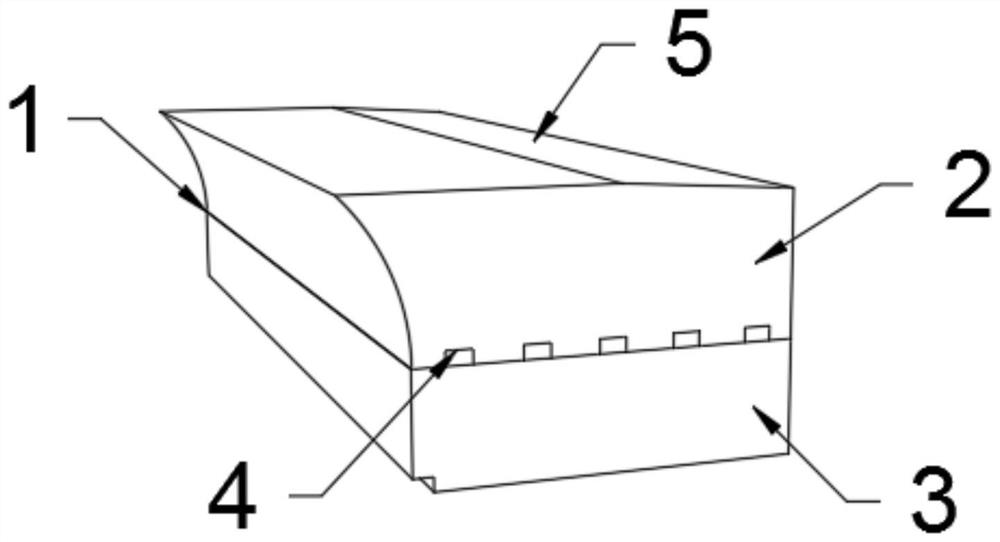

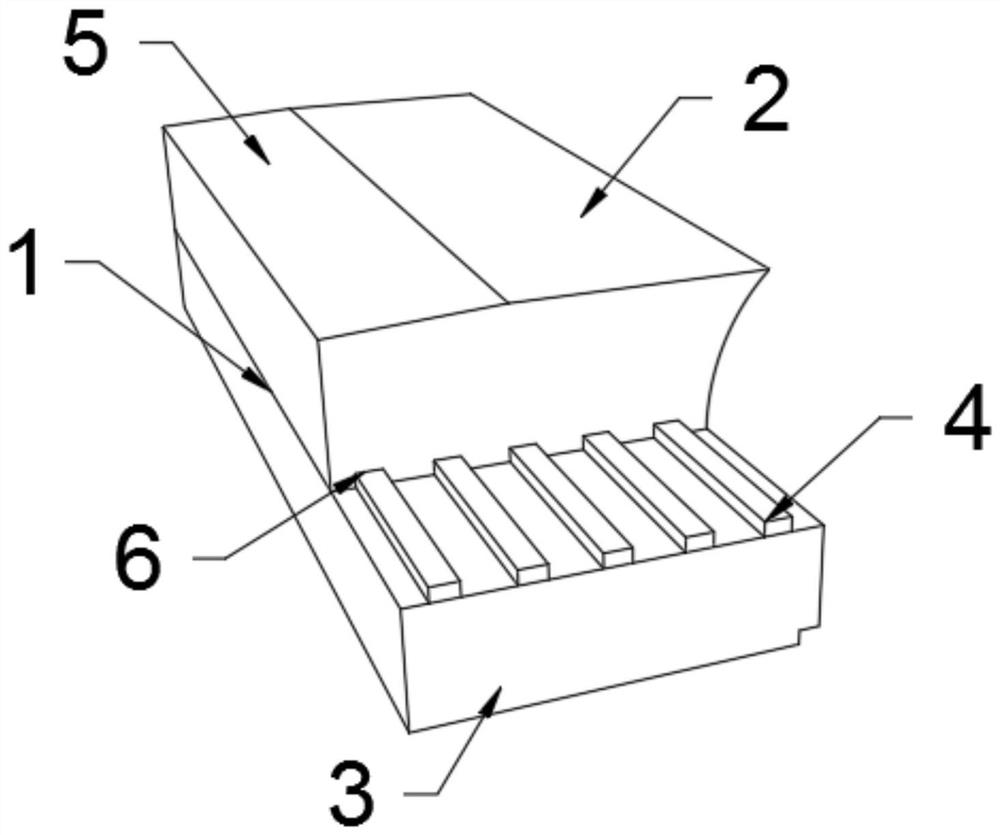

High-erosion-resistance lip brick for glass kiln and preparation method of high-erosion-resistance lip brick

A glass kiln and lip brick technology, applied in the field of lip bricks, can solve the problems of increasing the cost of processing and not being able to utilize the performance of lip bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A lip brick, which is a highly corrosion-resistant lip brick for a glass kiln, is made of the following raw materials in parts by mass:

[0060] High clay 40g, quartz 15g, feldspar 13g, talc powder 5g, refractory material 18g, anti-erosion material 12g, sodium tripolyphosphate 2g, water 20g.

[0061] Wherein, the refractory material includes the following raw material components in parts by weight: fused corundum powder 6g, dolomite powder 6g, ball clay 6g.

[0062] Wherein, the anti-corrosion material includes the following raw material components in parts by weight: 6g of chrome corundum, 3g of fused chromium oxide, and 3g of zirconia.

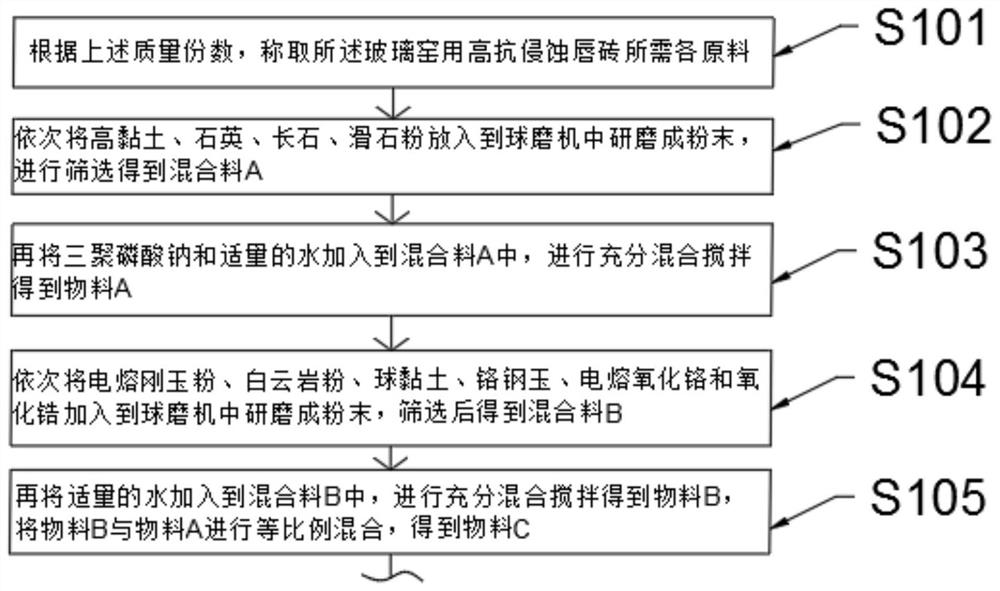

[0063] The preparation of the high erosion-resistant lip brick for the glass kiln includes the following steps:

[0064] Step S101: According to the above-mentioned parts by mass, weigh the raw materials required for the high-corrosion-resistant lip brick for the glass kiln;

[0065] Step S102: Put 40g of high clay, 15g of quartz, 1...

Embodiment 2

[0074] A lip brick, which is a high erosion-resistant lip brick for glass kilns, made of the following raw materials in parts by mass

[0075] High clay 50g, quartz 17.5g, feldspar 15g, talcum powder 6g, refractory material 21g, anti-erosion material 14g, sodium tripolyphosphate 2.2g, water 25g.

[0076] Wherein, the refractory material includes the following raw material components in parts by weight: fused corundum powder 7g, dolomite powder 7g, ball clay 7g.

[0077] Wherein, the anti-corrosion material includes the following raw material components in parts by weight: chrome corundum 7g, fused chromium oxide 3.5g, zirconia 3.5g.

[0078] The preparation of the high erosion-resistant lip brick for the glass kiln includes the following steps:

[0079] Step S101: According to the above-mentioned parts by mass, weigh the raw materials required for the high-corrosion-resistant lip brick for the glass kiln;

[0080] Step S102: Put 50g of high clay, 17.5g of quartz, 15g of feld...

Embodiment 3

[0089] A lip brick, which is a high erosion-resistant lip brick for glass kilns, made of the following raw materials in parts by mass

[0090] High clay 60g, quartz 20g, feldspar 17g, talcum powder 7g, refractory material 24g, anti-erosion material 16g, sodium tripolyphosphate 2.4g, water 30g.

[0091] Wherein, the refractory material includes the following raw material components in parts by weight: fused corundum powder 8g, dolomite powder 8g, ball clay 8g.

[0092] Wherein, the anti-corrosion material includes the following raw material components in parts by weight: 8 g of chrome corundum, 4 g of fused chromium oxide, and 4 g of zirconia.

[0093] The preparation of the high erosion-resistant lip brick for the glass kiln includes the following steps:

[0094] Step S101: According to the above-mentioned parts by mass, weigh the raw materials required for the high-corrosion-resistant lip brick for the glass kiln;

[0095] Step S102: Put 60g of high clay, 20g of quartz, 17g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com