Ear cap type high-temperature-resistant premixed combustion nozzle and control method thereof

A technology of premixed combustion and high temperature resistance, applied in the direction of combustion methods, burners, burners, etc., can solve the problems of temperature deformation of the burner nozzle shell, affect the service life of the nozzle, and affect the safe operation of the unit, so as to achieve sufficient and stable combustion , Improving the efficiency of the unit and preventing high temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

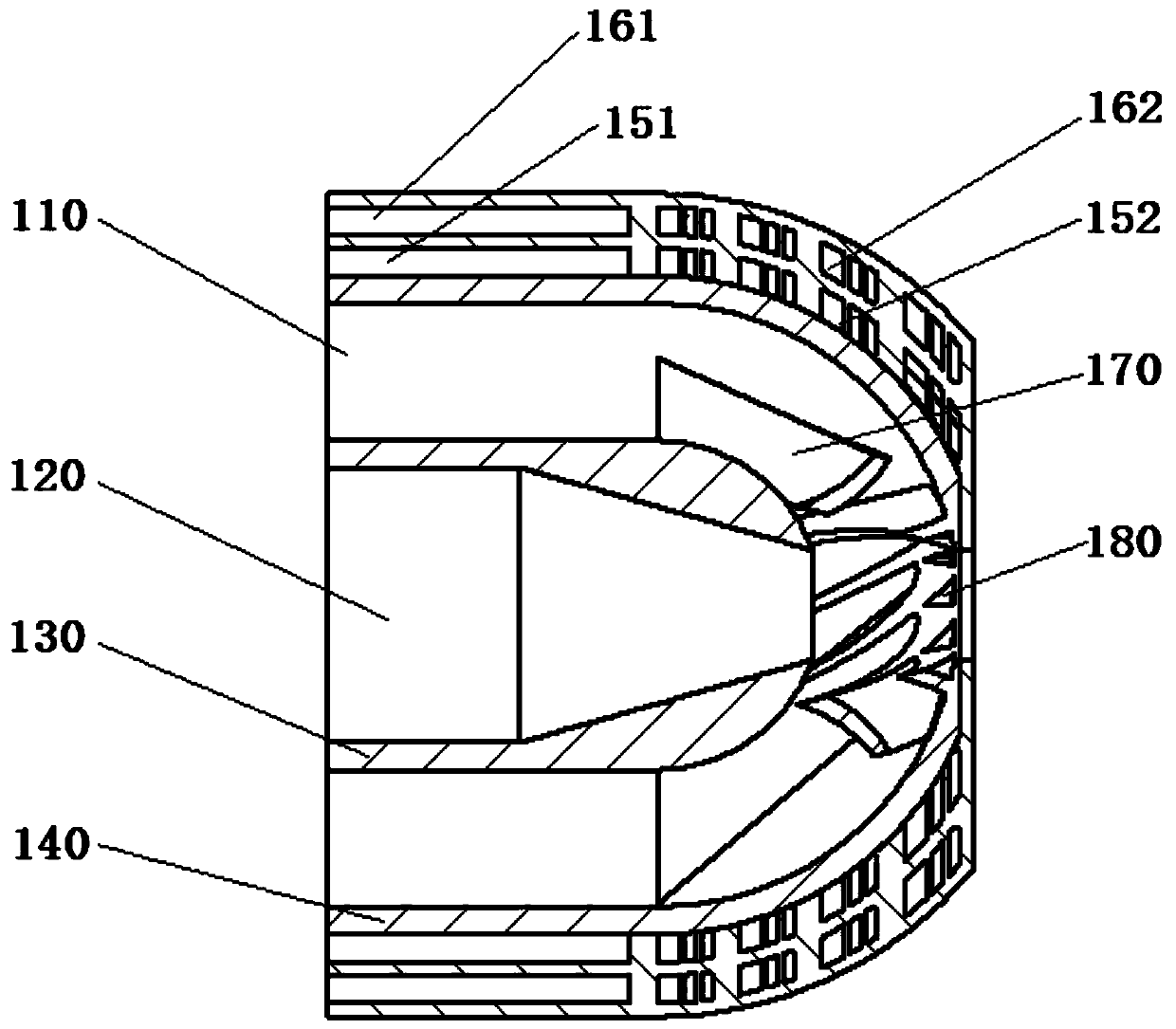

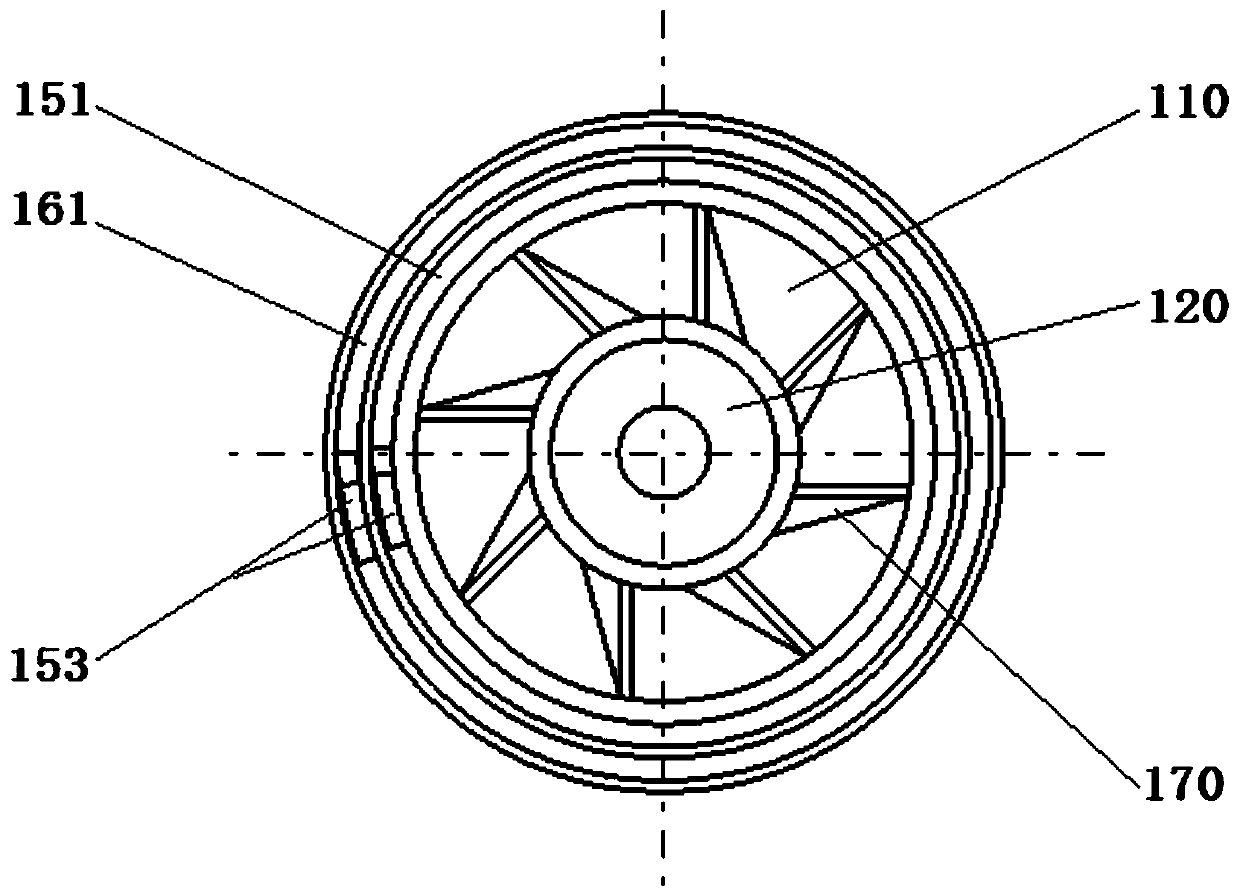

[0048] Such as Figure 1-6 As shown, the present invention provides an ear cap type anti-high temperature premixed combustion nozzle, including: a first channel 120, a second channel 110, a first housing 130, a second housing 140, a water outlet mechanism, a water inlet mechanism, a guide flow plate 170 .

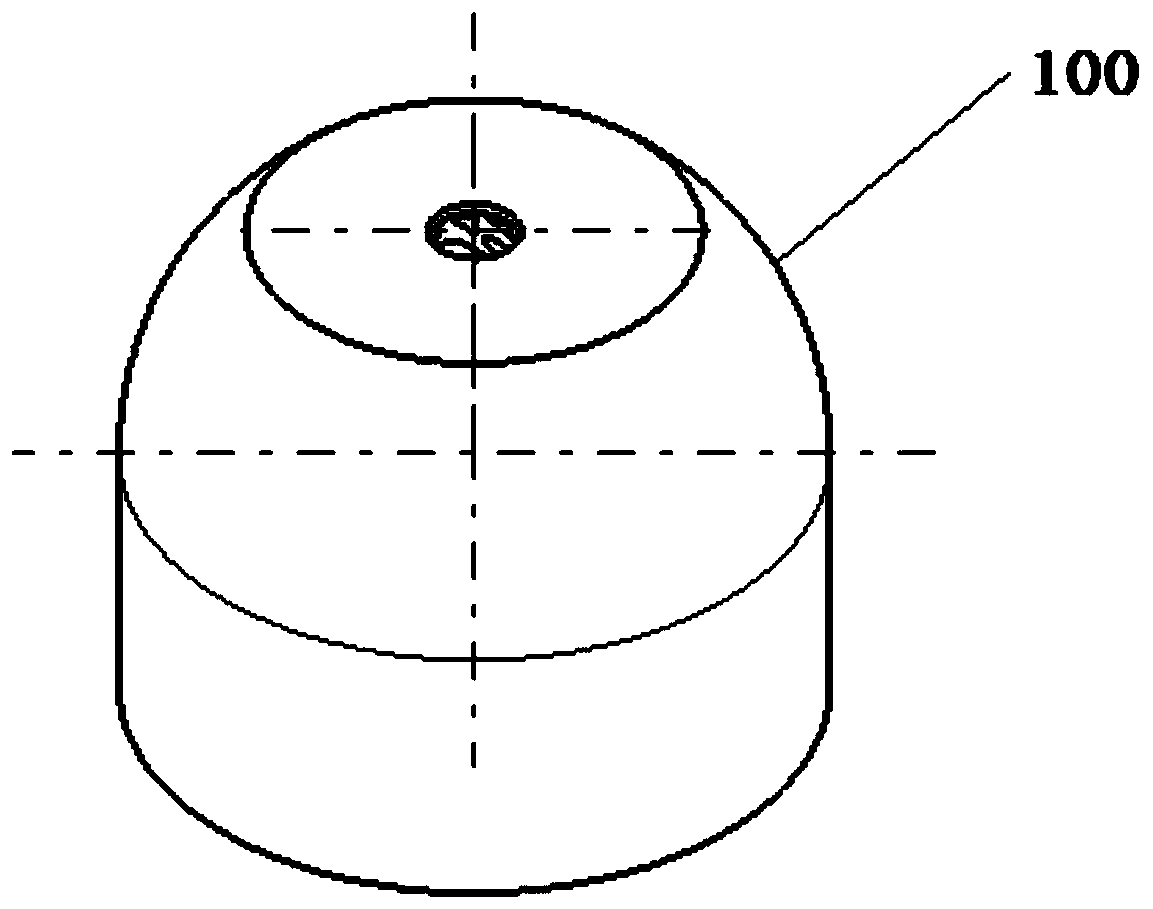

[0049] One end of the whole combustion nozzle is a cylindrical structure, the other end is a hemispherical structure with an opening, and the end face of the hemispherical structure is a planar structure.

[0050] One end of the first housing 130 is a cylindrical structure, and the other end is a hemispherical structure with an opening. The inside of the first housing 130 has a cavity, and the first passage 120 is arranged inside the first housing 130. The first passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com