High-temperature water cooling spiral conveyor

A screw conveyor and screw conveyor shaft technology, applied in the field of conveying machinery, can solve the problems of being unable to convey materials higher than 400°C, and achieve the effects of simple structure, clean environment and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

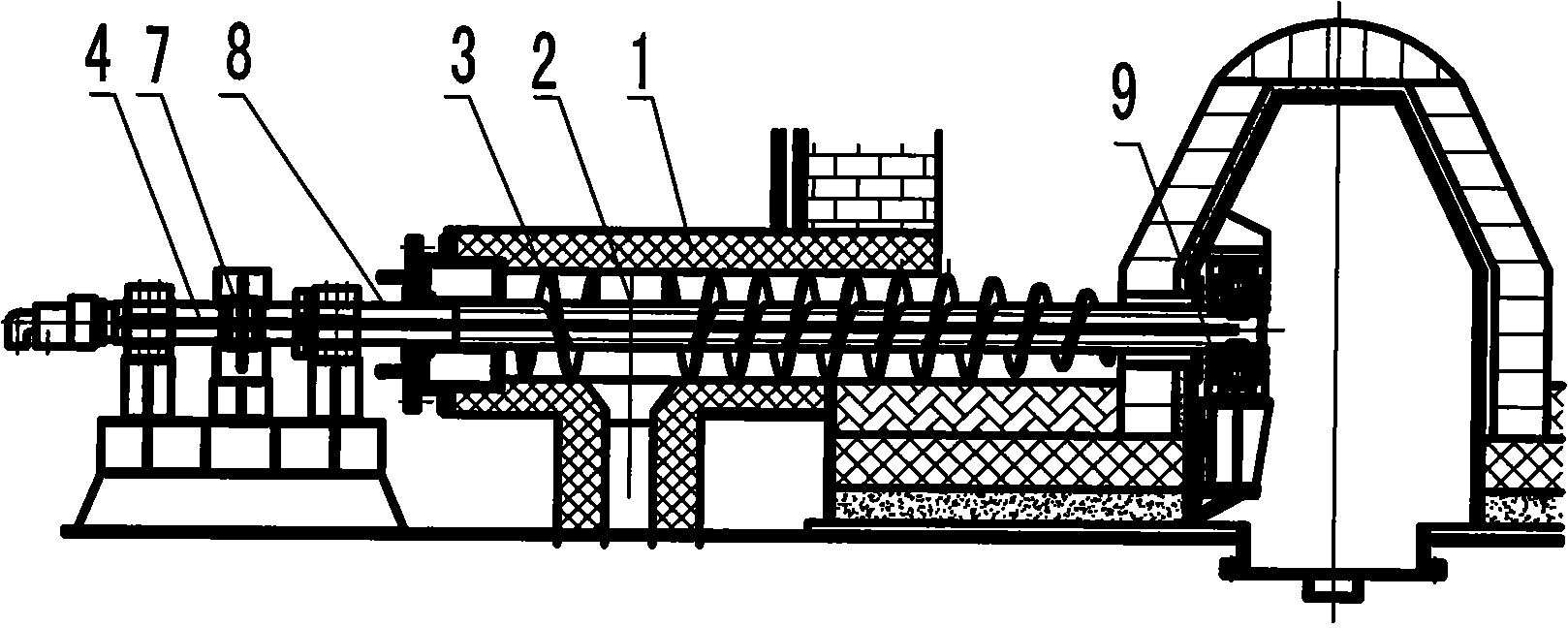

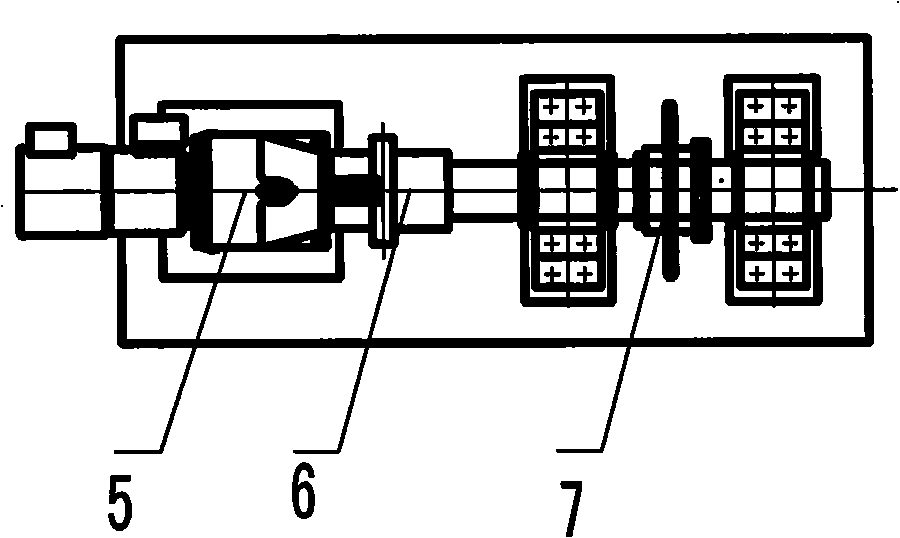

[0021] Such as figure 1 As shown, a high-temperature water-cooled screw conveyor of the present invention includes a motor, a casing 1 and a screw conveying shaft 2, the screw conveying shaft is installed in the casing, the motor is connected to the screw conveying shaft through a power transmission device, and the Spiral blades 3 are uniformly installed outside the screw conveying shaft, and a water cooling pipe 4 is installed inside the screw conveying shaft.

[0022] The screw conveying shaft and the screw blade are split structures.

[0023] The inner wall of the box is provided with a high-temperature-resistant and wear-resistant refractory material layer.

[0024] The screw conveying shaft, the screw blade and the box body are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com