Horizontal rotary tube cooked ball air water spray cooling machine

A rotary drum and water spray technology, applied in the field of horizontal rotary drum cooked ball air-water spray coolers, can solve the problems of insufficient sealing, air entering the drum, affecting product quality, etc., and achieve the effect of preventing high temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

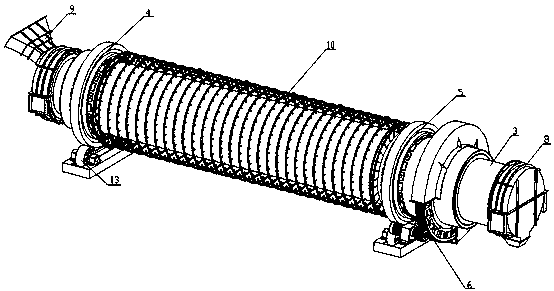

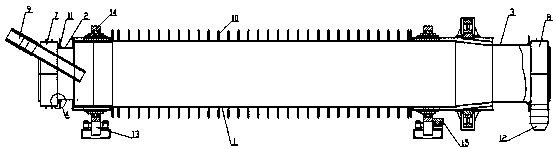

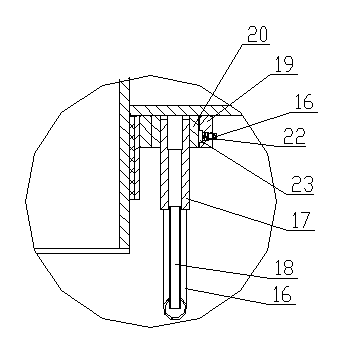

[0014] A horizontal rotary cylinder cooked ball air-water spray cooler, comprising a cooling cylinder 1 and an input cylinder 2 and an output cylinder 3 connected to the left and right ends of the cooling cylinder 1, and the outer circle of the left and right ends of the cooling cylinder 1 is provided with a supporting device. 4 and support device 2 5, the right side of support device 2 5 is provided with a transmission device 6, the left end of the input cylinder 2 is connected with a feed cylinder 7, the right end of the output cylinder 3 is connected with a discharge cylinder 8, and the feed cylinder 7 is provided with The feed pipe 9, the outer surface of the cooling cylinder 1 is provided with an air-water spray ring 10, and a nitrogen positive pressure chamber is used between the input cylinder 2 and the feed cylinder 7, and the output cylinder 3 and the discharge cylinder 8 The device 11 is sealed, and the inner wall of the feed pipe 9 is provided with a high-alumina ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com