Low-temperature glaze-fired ceramic product and preparing method thereof

A technology of ceramic products and low-temperature glaze, applied in the field of ceramic products, can solve the problems of affecting the income efficiency of manufacturers and the high cost of recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

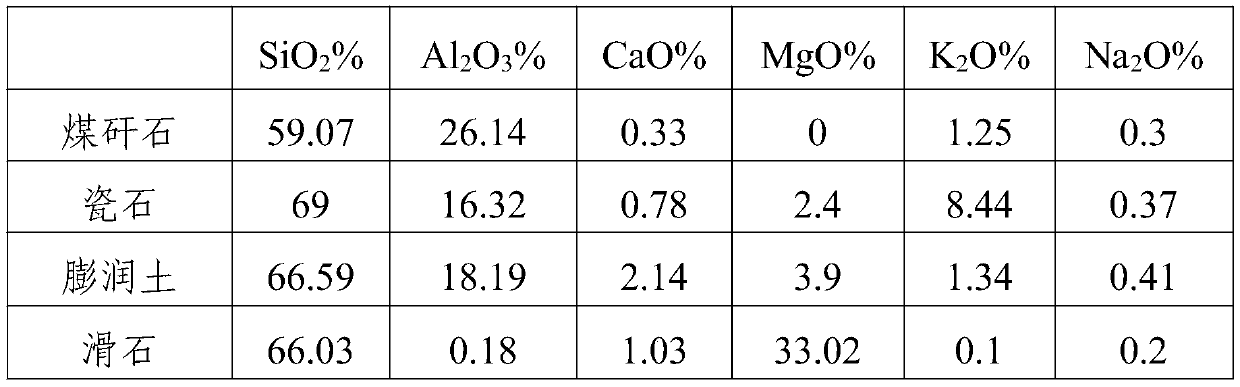

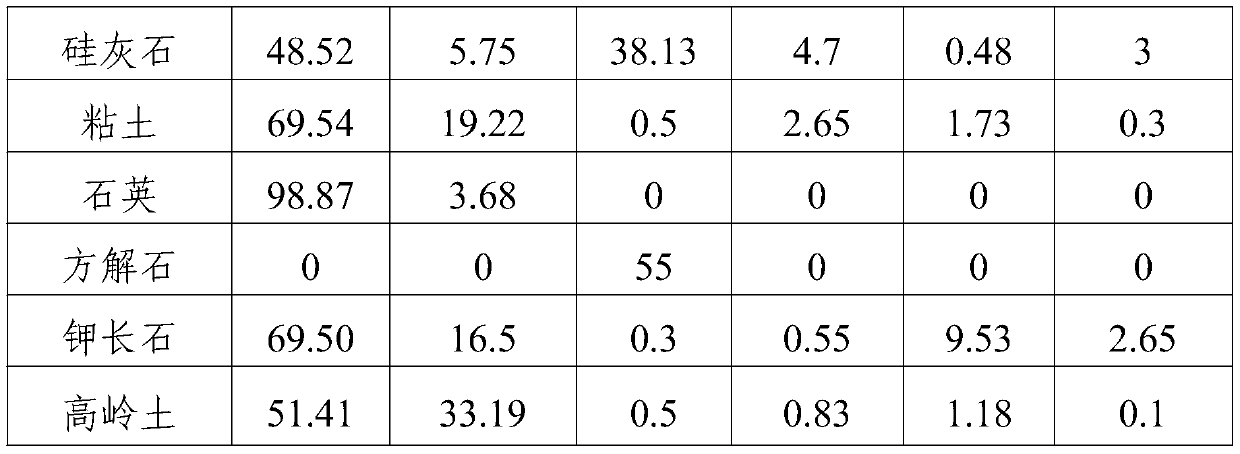

[0032] A low-temperature glaze-fired ceramic product. The low-temperature glaze-fired ceramic product is obtained by coating a low-temperature glaze on a ceramic body and drying and firing. The ceramic body includes the following raw materials in mass fractions: 35 parts of coal gangue, porcelain stone 46 parts, 7 parts of bentonite, 6 parts of talc, 12 parts of wollastonite, 7 parts of clay, 2 parts of quartz, 0.4 parts of sodium polyphosphate; the low-temperature glaze includes the following raw materials in mass fractions: 10 parts of calcite, 35 parts of quartz, potassium 17 parts of feldspar, 11 parts of kaolin, 16 parts of talc, 20 parts of barium carbonate, 16 parts of borax, 7 parts of zinc oxide, 0.3 part of sodium carboxymethyl cellulose.

[0033] The preparation method of the above-mentioned low-temperature glaze fired ceramic product comprises the following steps:

[0034] 1) Preparation of the ceramic green body: Weigh the raw materials of the ceramic green body i...

Embodiment 2

[0039]A low-temperature glaze-fired ceramic product. The low-temperature glaze-fired ceramic product is obtained by coating a low-temperature glaze on a ceramic body and drying and firing. The ceramic body includes the following raw materials in mass fractions: 30 parts of coal gangue, porcelain stone 48 parts, 5 parts of bentonite, 7 parts of talc, 6 parts of wollastonite, 9 parts of clay, 1 part of quartz, 0.5 parts of sodium polyphosphate; the low-temperature glaze includes the following raw materials in mass fractions: 5 parts of calcite, 36 parts of quartz, potassium 10 parts of feldspar, 14 parts of kaolin, 10 parts of talc, 23 parts of barium carbonate, 10 parts of borax, 9 parts of zinc oxide, 0.1 part of sodium carboxymethyl cellulose.

[0040] The preparation method of the above-mentioned low-temperature glaze fired ceramic product comprises the following steps:

[0041] 1) Preparation of the ceramic green body: Weigh the raw materials of the ceramic green body in pr...

Embodiment 3

[0046] A low-temperature glaze-fired ceramic product. The low-temperature glaze-fired ceramic product is obtained by coating a low-temperature glaze on a ceramic body and drying and firing. The ceramic body includes the following raw materials in mass fractions: 40 parts of coal gangue, porcelain stone 44 parts, 10 parts of bentonite, 5 parts of talc, 15 parts of wollastonite, 6 parts of clay, 3 parts of quartz, 0.3 parts of sodium polyphosphate; the low-temperature glaze includes the following raw materials in mass fractions: 15 parts of calcite, 2 parts of quartz, potassium 20 parts of feldspar, 10 parts of kaolin, 20 parts of talc, 18 parts of barium carbonate, 20 parts of borax, 6 parts of zinc oxide, 0.5 part of sodium carboxymethyl cellulose.

[0047] The preparation method of the above-mentioned low-temperature glaze fired ceramic product comprises the following steps:

[0048] 1) Preparation of the ceramic green body: Weigh the raw materials of the ceramic green body i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com