A kind of far-infrared self-generated glazed porcelain with high utilization of desert materials and its preparation process

A preparation process and self-generated glaze technology, which is applied in the field of ceramics, can solve the problems of being unable to adapt to the rapid cooling and rapid heating environment, poor toughness and strength, and poor thermal stability, so as to save mining costs, have good thermal stability, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

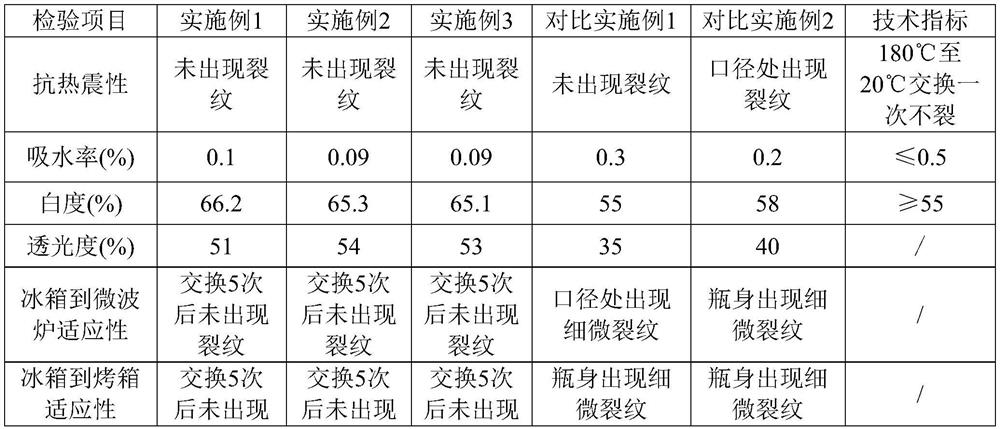

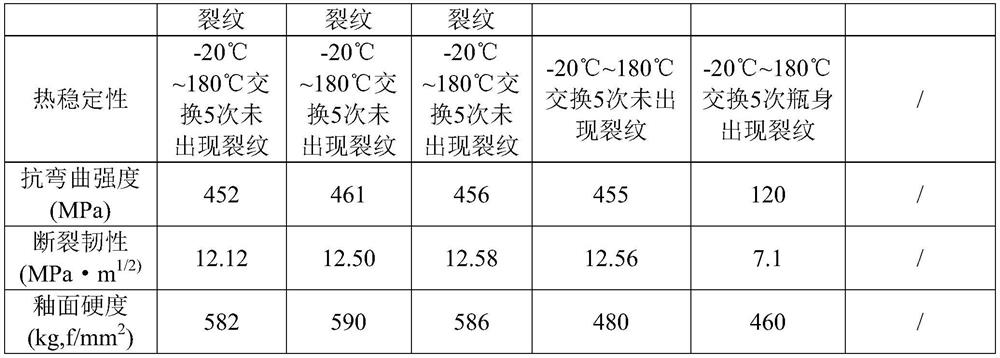

Embodiment 1

[0028] A kind of far-infrared self-generated glazed porcelain with high utilization of desert materials. The components and weight percentages of the self-generated glazed porcelain mud are: 50% of sand from the desert; 10% of pyrophyllite; 8% of purple wood knots; 10% of coal gangue; Base bentonite 2%; potassium feldspar 6%; albite 3%; micron spodumene 3%; zirconium silicate 2%; wollastonite 6%.

[0029] Preferably, the chemical composition in the authigenic enamel slurry is by weight percentage: SiO 2 : 60%; Al 2 o 3 : 20%; CaO: 4.5%; ZrO 2 : 5.0%; Na 2 O+K 2 O: 4.6%; Fe 2 o 3 : 1.2%; MgO: 2.8%; LiO 2 : 0.8%; TiO 2 : 1.0%; P 2 o 5 : 0.1%.

[0030] Preferably, the technological process for preparing the above-mentioned autogenous glazed porcelain mud is as follows: 50% sand from the desert, 10% pyrophyllite, 8% purple wood knots, 10% coal gangue, 2% magnesium-based bentonite, 6% potassium feldspar, 3% albite, 3% micron spodumene, 2% zirconium silicate and 6% nano ...

Embodiment 2

[0035] A kind of far-infrared self-generated glazed porcelain with high utilization of desert materials. The components and weight percentages of the self-generated glazed porcelain mud are: 55% of sand grains taken from the desert; 8% of pyrophyllite; 6% of purple wood knots; 11% of coal gangue; Base bentonite 3%; potassium feldspar 4%; albite feldspar 4%; micron spodumene 1%; zirconium silicate 4%; wollastonite 4%.

[0036] Preferably, the chemical composition in the authigenic enamel slurry is by weight percentage: SiO 2 : 65%; Al 2 o 3 : 18%; CaO: 3%; ZrO 2 : 4%; Na 2 O+K 2 O: 3.2%; Fe 2 o 3 : 1.8%; MgO: 3.2%; LiO 2 : 1%; TiO 2 : 0.75%; P 2 o 5 : 0.05%.

[0037] Preferably, the technological process for preparing the above-mentioned autogenous glazed porcelain mud is as follows: 55% of sand from the desert, 8% of pyrophyllite, 6% of purple wood knots, 11% of coal gangue, 3% magnesium-based bentonite, 4% potassium feldspar, 4% albite, 1% micron spodumene, 4% zir...

Embodiment 3

[0042] A kind of far-infrared self-generated glazed porcelain with high utilization of desert materials. The components and weight percentages of the self-generated glazed porcelain mud are: 45% of sand grains taken from the desert; 9% of pyrophyllite; 7% of purple wood knots; 13% of coal gangue; Base bentonite 4%; potassium feldspar 8%; albite 4%; micron spodumene 2%; zirconium silicate 3%; wollastonite 5%.

[0043] Preferably, the chemical composition in the authigenic enamel slurry is by weight percentage: SiO 2 : 70%; Al 2 o 3 : 15%; CaO: 2.0%; ZrO 2 : 3.5%; Na 2 O+K 2 O: 2.6%; Fe 2 o 3 : 2.0%; MgO: 3.5%; LiO 2 : 0.8%; TiO 2 : 0.5%; P 2 o 5 : 0.1%.

[0044] Preferably, the technological process for preparing the above-mentioned autogenous glazed porcelain mud is as follows: 45% of sand from the desert, 9% of pyrophyllite, 7% of purple wood knots, 13% of coal gangue, 4% magnesium-based bentonite, 8% potassium feldspar, 4% albite, 2% micron spodumene, 3% zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com