Glaze coloured decoration daily use poocelain and its production method

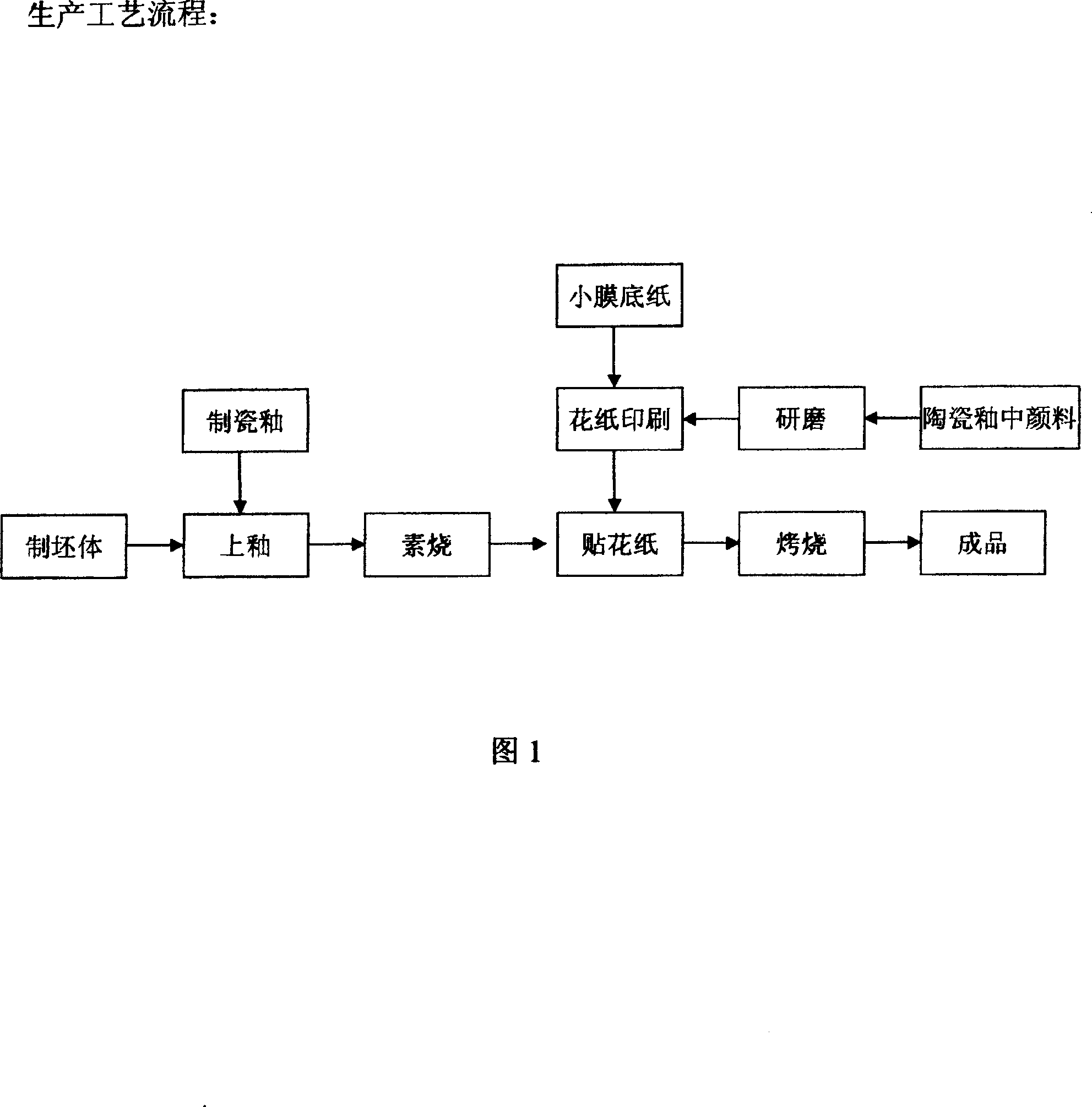

A production method and a technique for daily-use porcelain, which are applied to in-glaze color decorative daily-use porcelain and its production field, can solve the problems of difficulty in industrialized production, not bright enough color, and few varieties of designs and colors, and achieve less lead and cadmium dissolution and less color Colorful, glazed hard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below by taking an in-glaze decorative porcelain plate with a pattern of red roses as an example.

[0021] The in-glaze decorative porcelain plate, the green body includes the following components by weight percentage: 18% of Longyan soil raw ore, 11% of weathered potassium feldspar, 12% of Jiepai soil, 10% of potassium feldspar, 9% of calcined alumina, Guizhou soil 5%, Longyan soil wash mud 23%, quartz 12%.

[0022] The production method of the in-glaze decorative porcelain plate comprises the following steps:

[0023] (1) Blank body: first prepare mud material, add water ball mill, sieve to remove iron, press filter, rough scouring, stale, scouring, molding, and drying to make a porcelain plate blank.

[0024] (2) Making enamel: enamel includes the following components by weight percentage: waste porcelain powder 22%, feldspar 11%, lithium china stone powder 4%, quartz 25%, kaolin 10%, zinc oxide 5%, dolomite 11% , C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com