Coating material preventing carbon deposition of coke oven and method for making same

A technology for coating materials and furnace doors, applied in the heating of coke ovens, doors/closers of coke ovens, coatings, etc., can solve the problems of low melting point of glazes and inapplicability of glazes, and achieve high hardness of glazed surfaces , Excellent thermal shock resistance and good long-term durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Select raw materials of the following specifications:

[0026] Li in lepidolite 2 O≥3.5%, fineness2 O+Na 2 O is 11-15%, K 2 O:Na 2 O>2, Fe 2 o 3 +TiO 2 2 ≥60%, fineness2 o 3 ≥35%, fineness ≤0.045mm; Al in activated alumina powder 2 o 3 ≥98%, the average diameter of powder 2 ≥95%, fineness <0.088mm.

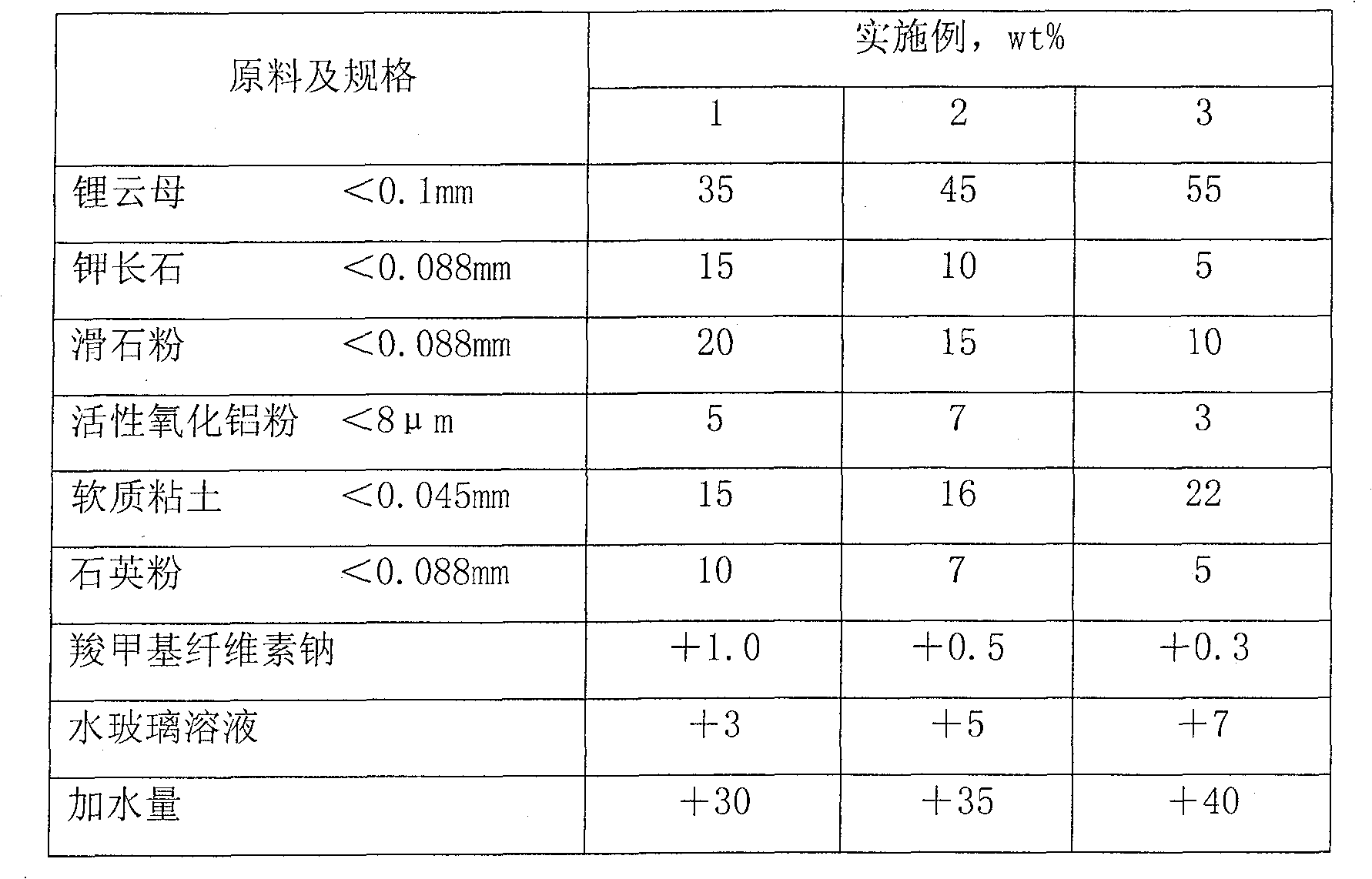

[0027] The embodiment coating material that will meet above requirement is according to following table proportioning:

[0028] The composition of table 1 embodiment

[0029]

[0030] The above mixture is stirred to form a slurry, which is manually applied or sprayed on the inner lining substrate of the furnace door with special equipment, and the thickness of the coating is controlled at 1.5-3.0mm. After natural drying and firing, the surface of the furnace door can form a solid, smooth and dense enamel layer with excellent thermal shock resistance and obvious anti-carbon effect. The conditions for the coating material to form a glaze layer are also very fle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com