Copper-based golden red glaze and preparation method thereof

A technology of copper-based and red glaze, which is applied in the field of copper-based red-gold glaze and its preparation, can solve the problems of increasing the production cost of red-gold glaze, difficult control of the preparation process, and reduced artistic appreciation, and achieves good gloss and melting temperature The effect of widening the range and full glaze color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

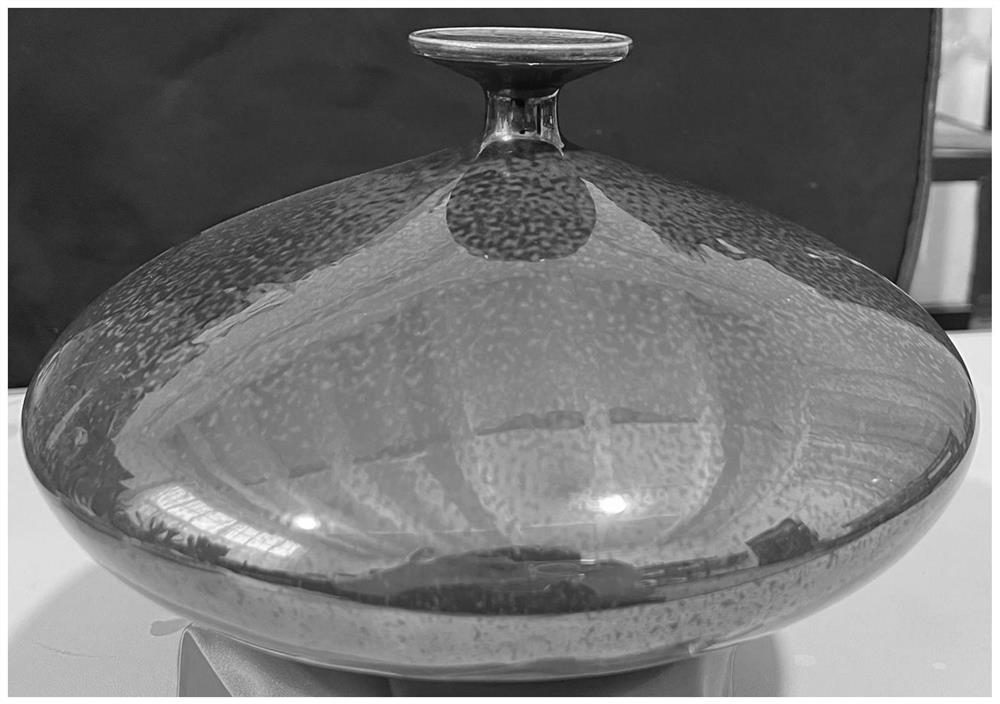

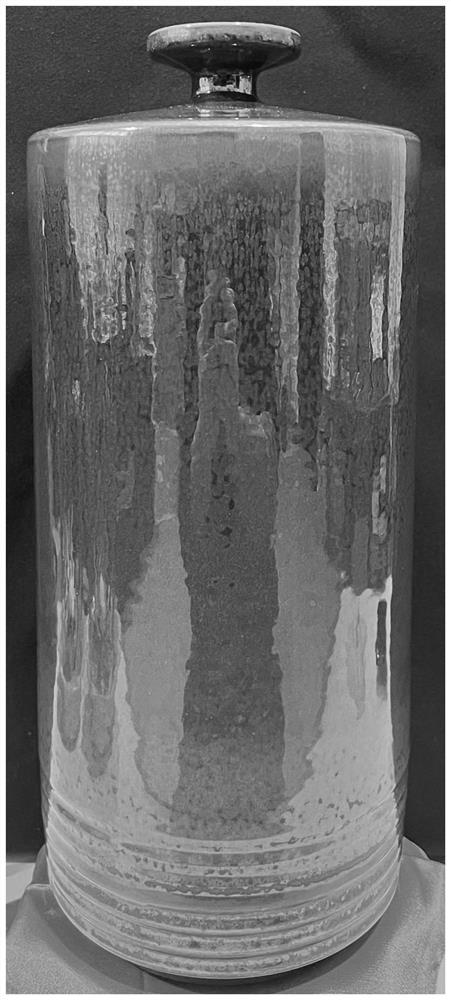

Image

Examples

Embodiment 1

[0031] A copper-based golden-red glaze, which is prepared from the following raw materials in weight percentages: 48% feldspar, 18.5% white feldspar, 18% calcite, 8.5% quartz, 2% copper ore, 4% ZnO, SnO 2 0.6%, CuO0.4%.

[0032] The preparation method of described copper-based golden red glaze, comprises the steps:

[0033] (1) Batching: take various raw materials according to the proportioning ratio of the above-mentioned copper-based golden red glaze;

[0034] (2) Preparation of glaze slurry: Add the glaze composed of the above various raw materials into a ball mill, add water and ball mill, wherein the mass ratio of glaze, ball, and water is 1:1.8:0.5, and the ball milling time is 32h, and the obtained concentration is 58% glaze slurry;

[0035] (3) Glazing: Stir the glaze slurry obtained in step (2) evenly to remove air bubbles on the glaze surface, place the green body that has been bisque-fired and have a clean surface in the evenly stirred glaze slurry for dipping, an...

Embodiment 2

[0048] A copper-based golden-red glaze, which is prepared from the following raw materials in weight percentages: 48.5% feldspar, 18% white feldspar, 17% calcite, 9% quartz, 3% copper ore, 3% ZnO, SnO 2 1%, CuO0.5%.

[0049] The preparation method of described copper-based golden red glaze, comprises the steps:

[0050] (1) Batching: take various raw materials according to the proportioning ratio of the above-mentioned copper-based golden red glaze;

[0051] (2) Preparation of glaze slurry: Add the glaze material composed of the above various raw materials into a ball mill, add water and ball mill, wherein the mass ratio of glaze material, ball and water is 1:1.9:0.6, and the ball milling time is 36h, and the obtained concentration is 59% glaze slurry;

[0052] (3) Glazing: Stir the glaze slurry obtained in step (2) evenly to remove air bubbles on the glaze surface, place the green body that has been bisque-fired and have a clean surface in the evenly stirred glaze slurry for ...

Embodiment 3

[0056] A copper-based golden-red glaze, which is prepared from the following raw materials in weight percentage: 49% of feldspar, 20% of white feldspar, 16.5% of calcite, 8% of quartz, 3.3% of copper ore, ZnO2%, SnO 2 0.8%, CuO0.4%.

[0057] The preparation method of described copper-based golden red glaze, comprises the steps:

[0058] (1) Batching: take various raw materials according to the proportioning ratio of the above-mentioned copper-based golden red glaze;

[0059] (2) Preparation of glaze slurry: Add the glaze material composed of the above various raw materials into a ball mill, add water and ball mill, wherein the mass ratio of glaze material, ball and water is 1:2:0.6, and the ball milling time is 35h, and the obtained concentration is 58% glaze slurry;

[0060] (3) Glazing: Stir the glaze slurry obtained in step (2) evenly to remove air bubbles on the glaze surface, place the green body that has been bisque-fired and have a clean surface in the evenly stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com