Method for firing domestic porcelain

A porcelain and daily-use technology, which is applied in the firing field of high-grade daily-use porcelain such as bowls and cups, can solve problems such as deformation, and achieve the effects of light shape, convenient operation, and high rate of high-quality products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one builds the firing of " white porcelain " rice bowl

[0023] Step 1: Take 10kg of "Jianbai Porcelain" clay that has been vacuum-fired;

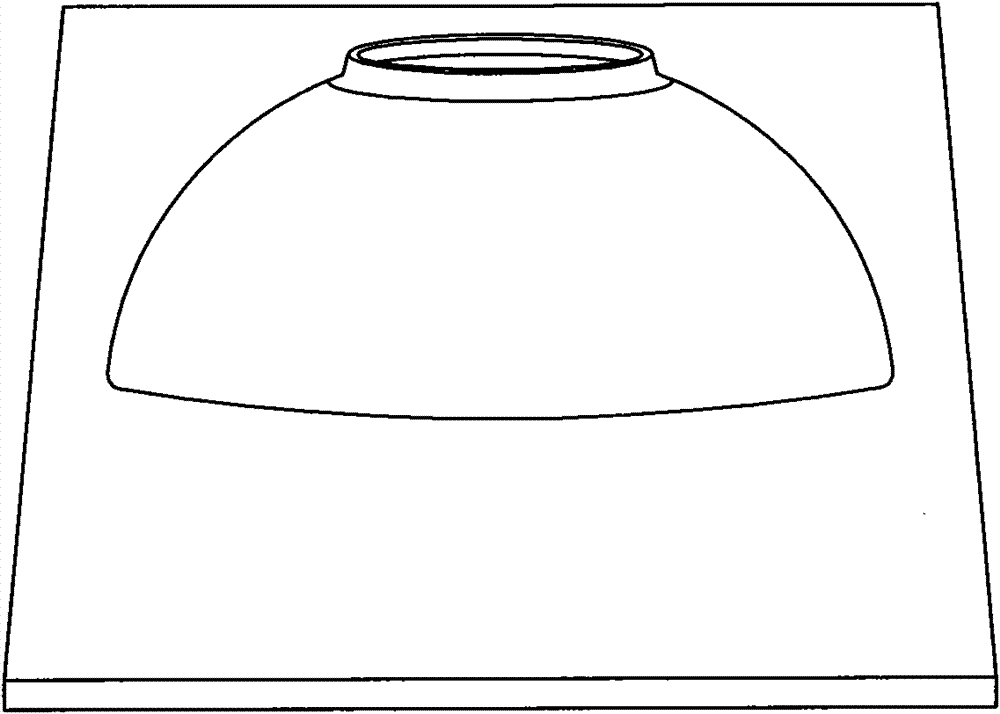

[0024] Step 2, making 10 green bodies of the rice bowl with the female die roll forming;

[0025] Step 3, after trimming, buckle it on the cake pad and dry it;

[0026] Step 4, put the green body into the kiln and biscuit once at a low temperature of 900°C;

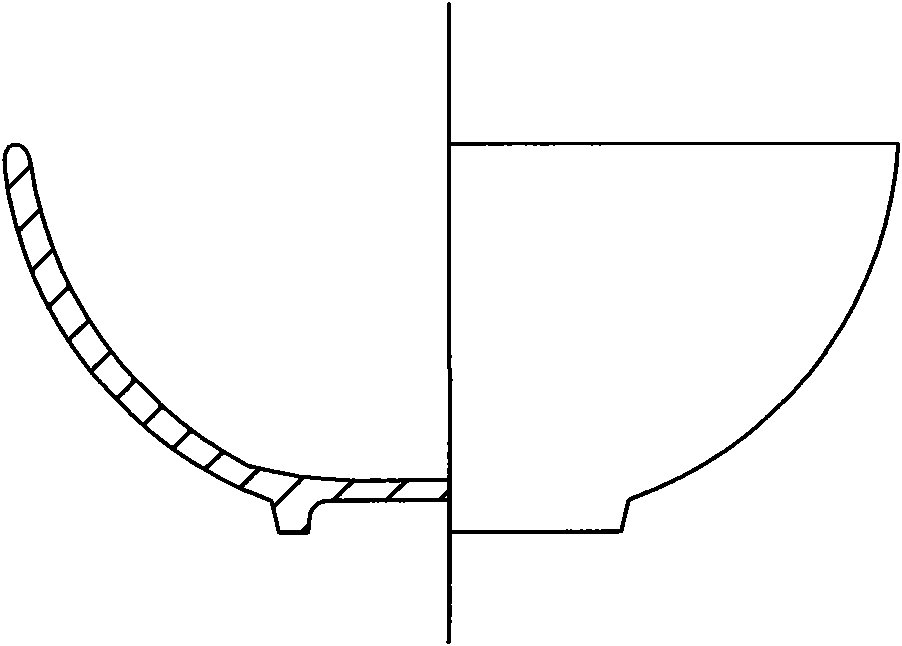

[0027] Step 5: After polishing the biscuit body, evenly apply a layer of "Jianbai Porcelain" glaze on the front and back sides of the body;

[0028] Step 6: Use a damp sponge to carefully wipe off the glaze layer on the edge of the bowl and the bottom foot;

[0029] Step 7, smoothing the surface of the silicon carbide refractory shed plate coated with alumina paint;

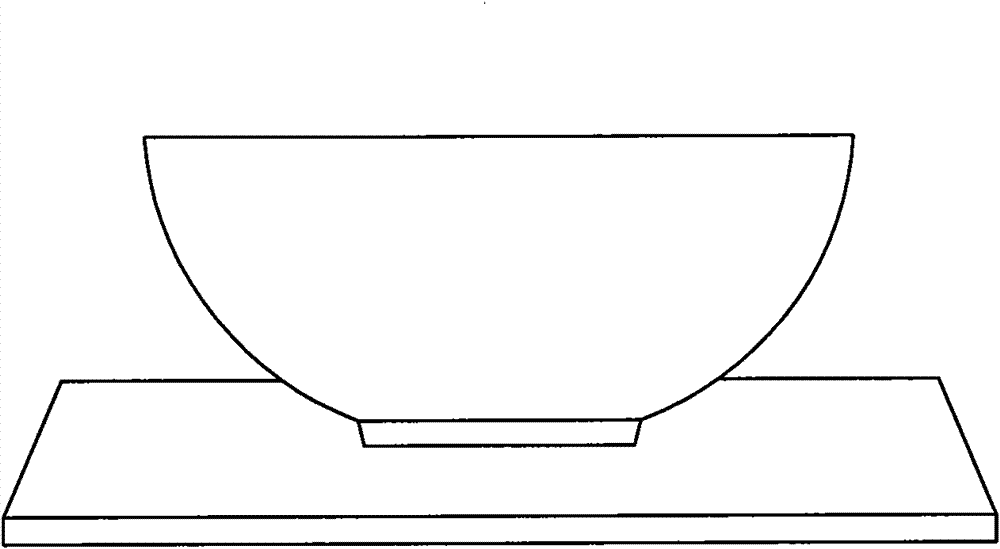

[0030] Step 8, carefully turn the glaze body upside down on the refractory shed, pay attention not to touch the bowls, and leave a proper gap;

[0031] Step 9: According to the firing curve tempera...

Embodiment 2

[0034] In step 12, after cooling, the finished product can be obtained, and the high-quality product rate of the finished product is 90%, and the qualified rate is 100%. The firing of embodiment two high-grade teacups

[0035] Step 1, take 15kg of porcelain clay that has been vacuum-fired;

[0036] Step 2, make 20 green bodies of teacups with female mold roll forming;

[0037] Step 3, after trimming, buckle it on the cake pad and dry it;

[0038] Step 4, put the body into the kiln and biscuit once at a low temperature of 850°C;

[0039] Step five, after polishing the biscuit body, apply a layer of enamel evenly on both sides of the body;

[0040] Step 6, use a damp sponge to carefully wipe off the glaze layer on the edge of the cup and the bottom foot;

[0041] Step 7, smoothing the surface of the silicon carbide refractory shed plate coated with alumina paint;

[0042] Step 8, carefully turn the glaze body upside down on the refractory shed board, pay attention not to to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com