Manufacturing method and application of superlarge, superlong and superflat continuous bearing motion table-board

A manufacturing method and ultra-long technology, which are applied in manufacturing tools, glass pressing, glass manufacturing equipment, etc., can solve the problems of difficult to realize the processing and manufacturing of ultra-large continuous bearing motion table, high cost, and difficult development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

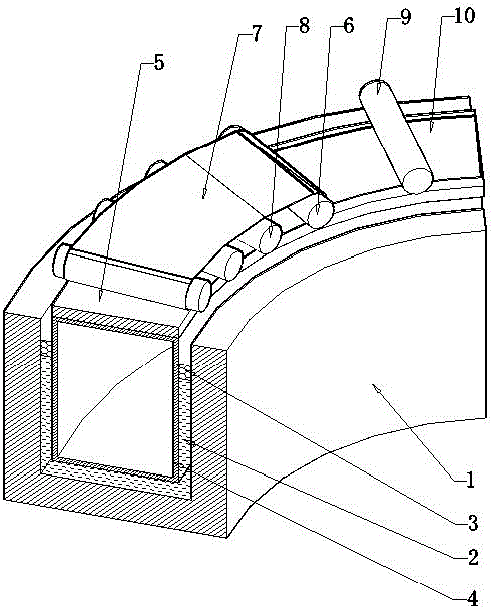

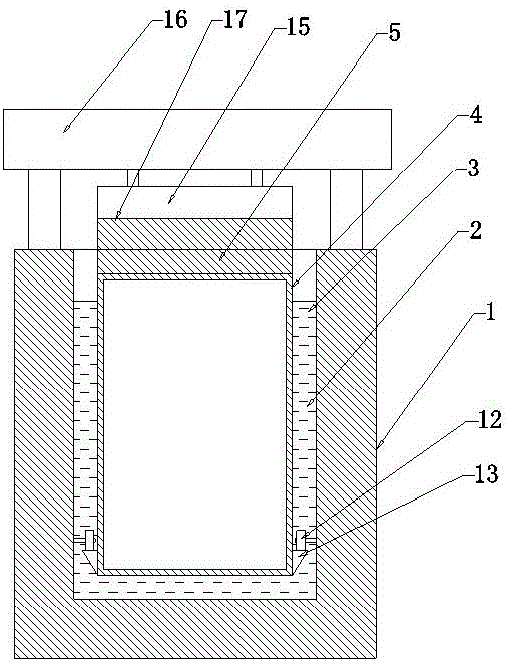

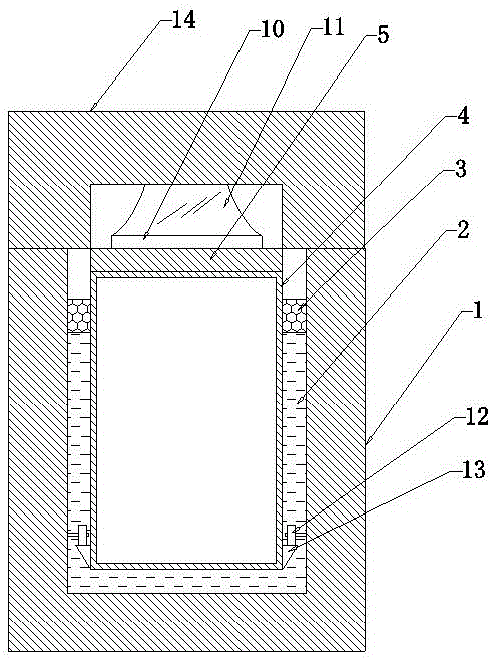

[0013] figure 1 , figure 2 In the process, the above-mentioned ultra-large, ultra-long, ultra-flat, and continuous bearing moving table is used for flat glass forming and annealing; the method is: the flowing glass melt 11 is sent to the above-mentioned ultra-large, ultra-long On the super-flat, continuous bearing rotary workbench 5, and use the workbench 5 as a continuous molding template; on the upper surface of the flattened molten glass 10, use the initial pressure roller 9 to roll, and the fan-shaped annular belt 7, and the fan-shaped annular belt The inner pressure roller 8 pressurizes and other methods to adjust the thickness of the glass liquid; and on the upper and lower surfaces of the glass liquid or the glass plate, the viscosity and temperature of the glass liquid or the glass plate are adjusted by heating or cooling, so as to achieve the shape of the glass plate , annealing or tempering purposes; since the upper and lower surfaces of the glass plate are clamped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com