Transferring device with ceramic part

A technology of conveying device and ceramic parts, which is applied in conveyors, transportation and packaging, etc., can solve the problems of deformation of the workpiece to be heated by the conveyor belt, and achieve the effects of preventing high temperature deformation, high melting point and good thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

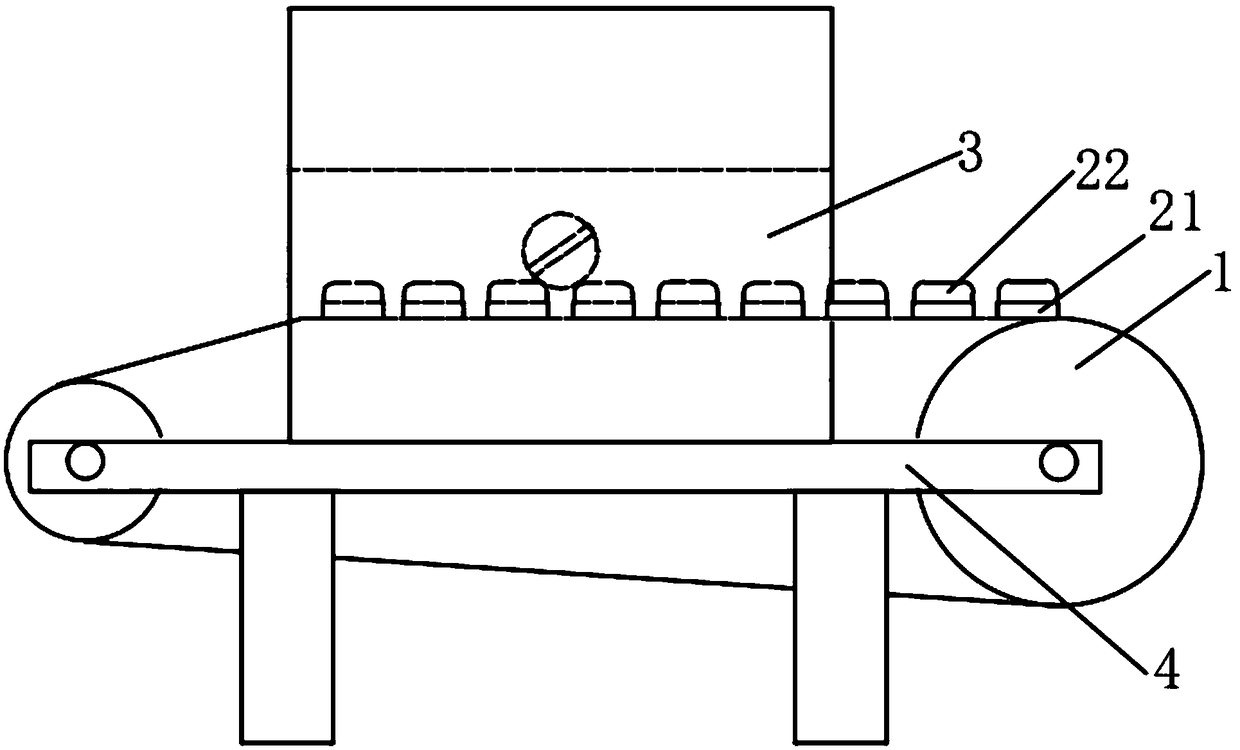

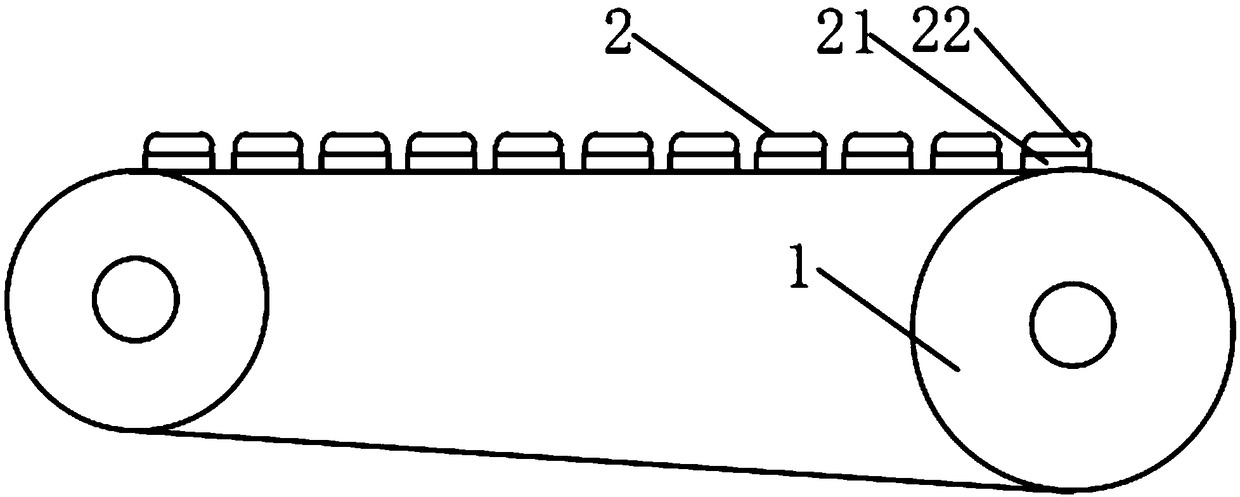

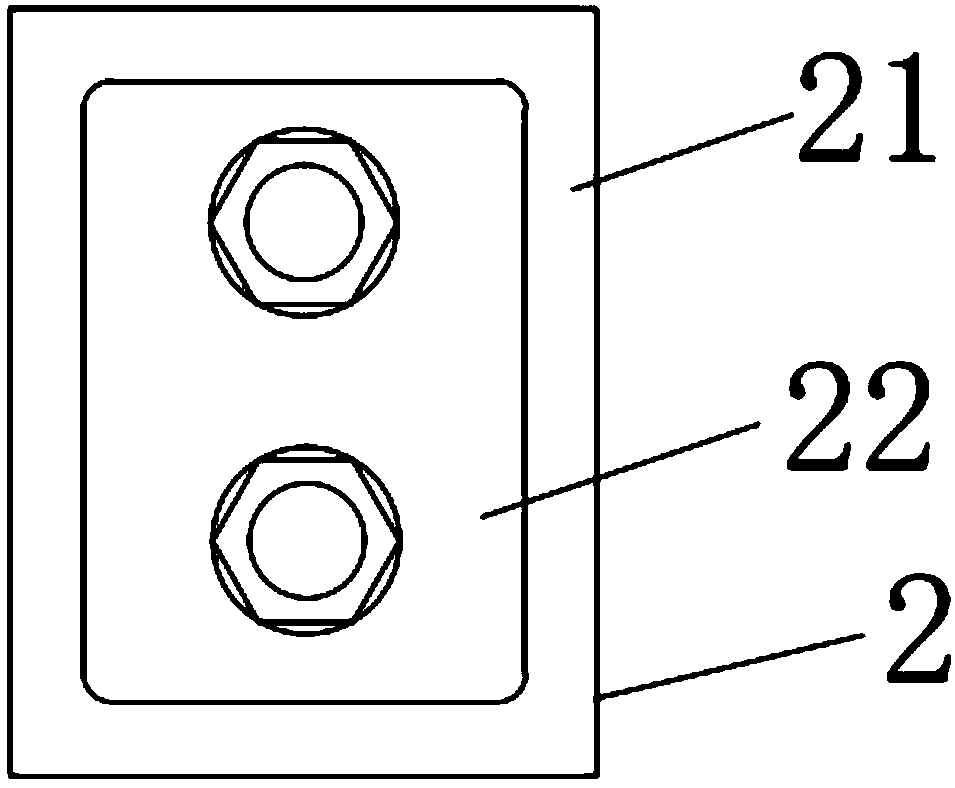

[0015] Such as figure 1 As shown, a conveyor with ceramic parts, including drive mechanism 1 and 2 crawler conveyor belts. The crawler conveyor belt includes track shoes 21 and ceramic parts 22 . The ceramic part 12 is fixed on the track shoe 21 . The ceramic piece 22 can be a rectangular or circular plate-like piece. The ceramic part 22 is within the surface range of the track shoe 21 and the upper surface of the ceramic part 22 is higher than the upper surface of the track shoe 21 . The ceramic part 22 can be fixed on the track shoe 21 by bolts.

[0016] When the conveyor belt is a metal crawler conveyor belt, the conveyor device can be used in various heating equipment, especially in super-audio heating equipment where the cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com