Positive pressure encapsulation device of building integrated photovoltaics (BIPV) solar energy component

A technology for solar modules and packaging equipment, applied in electrical components, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of inconsistent glass heating, uncompacted double-glass modules, inconsistent stress release, etc., to achieve a solid and firm structure. , The effect of solving the compaction and enhancing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

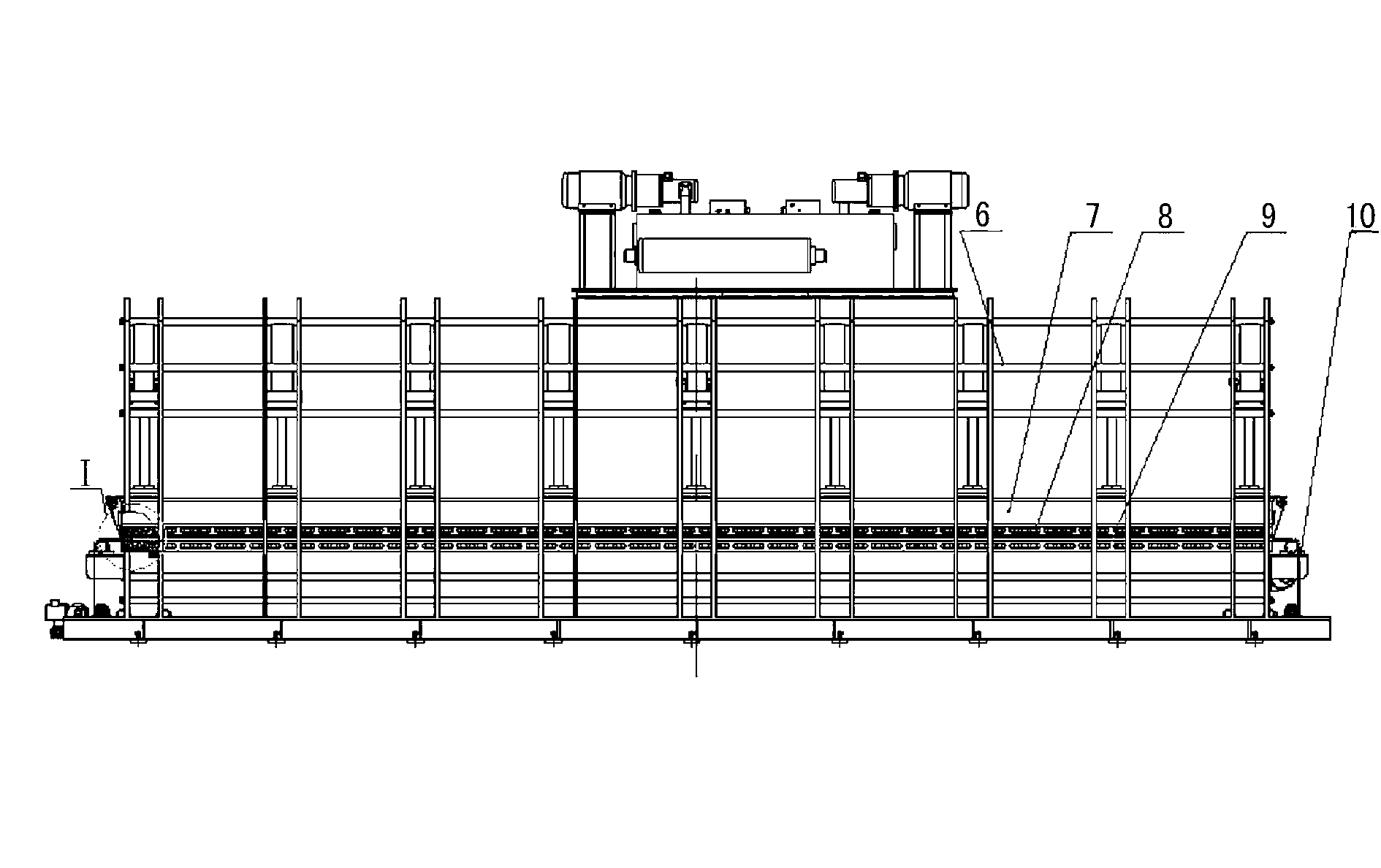

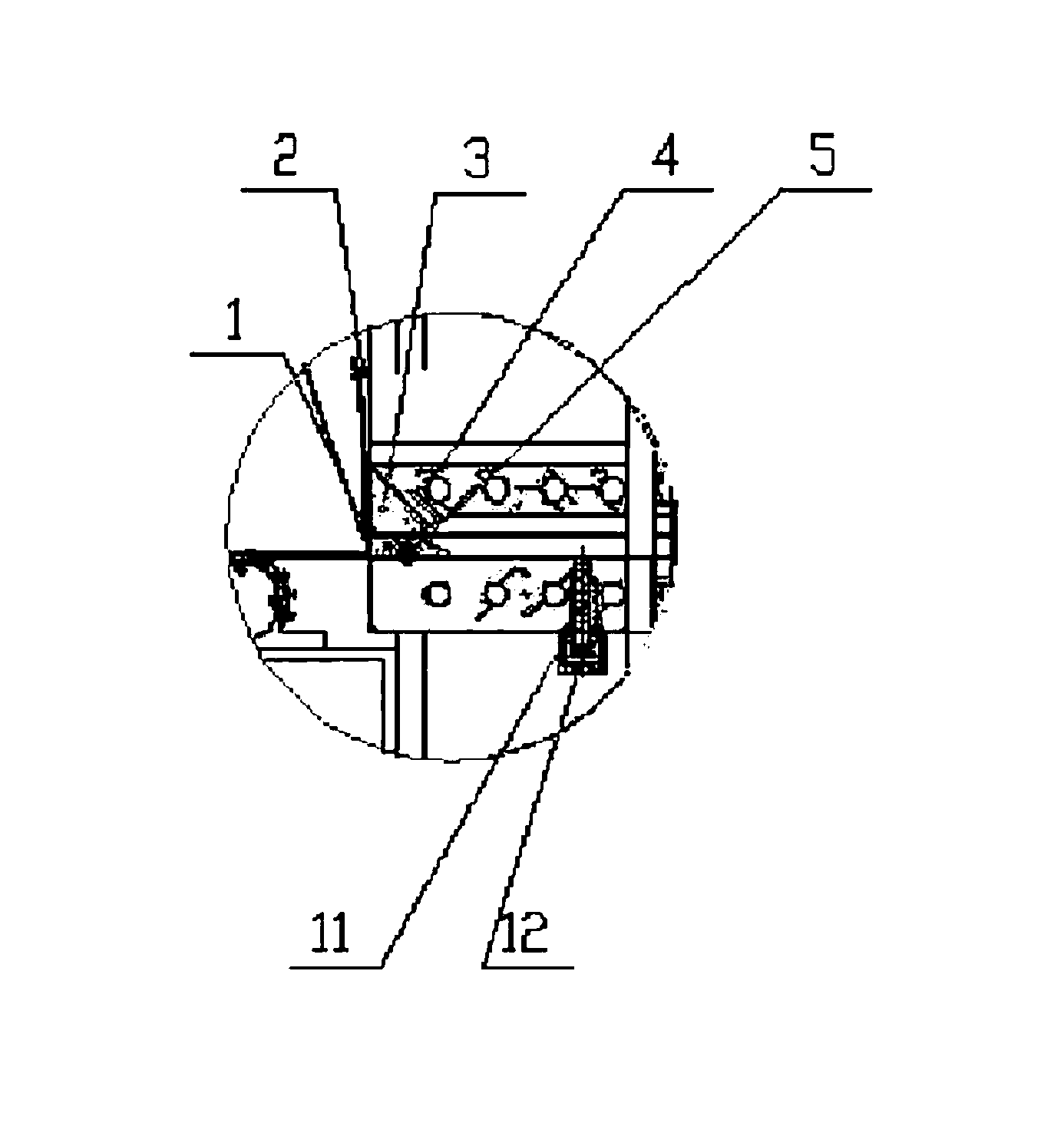

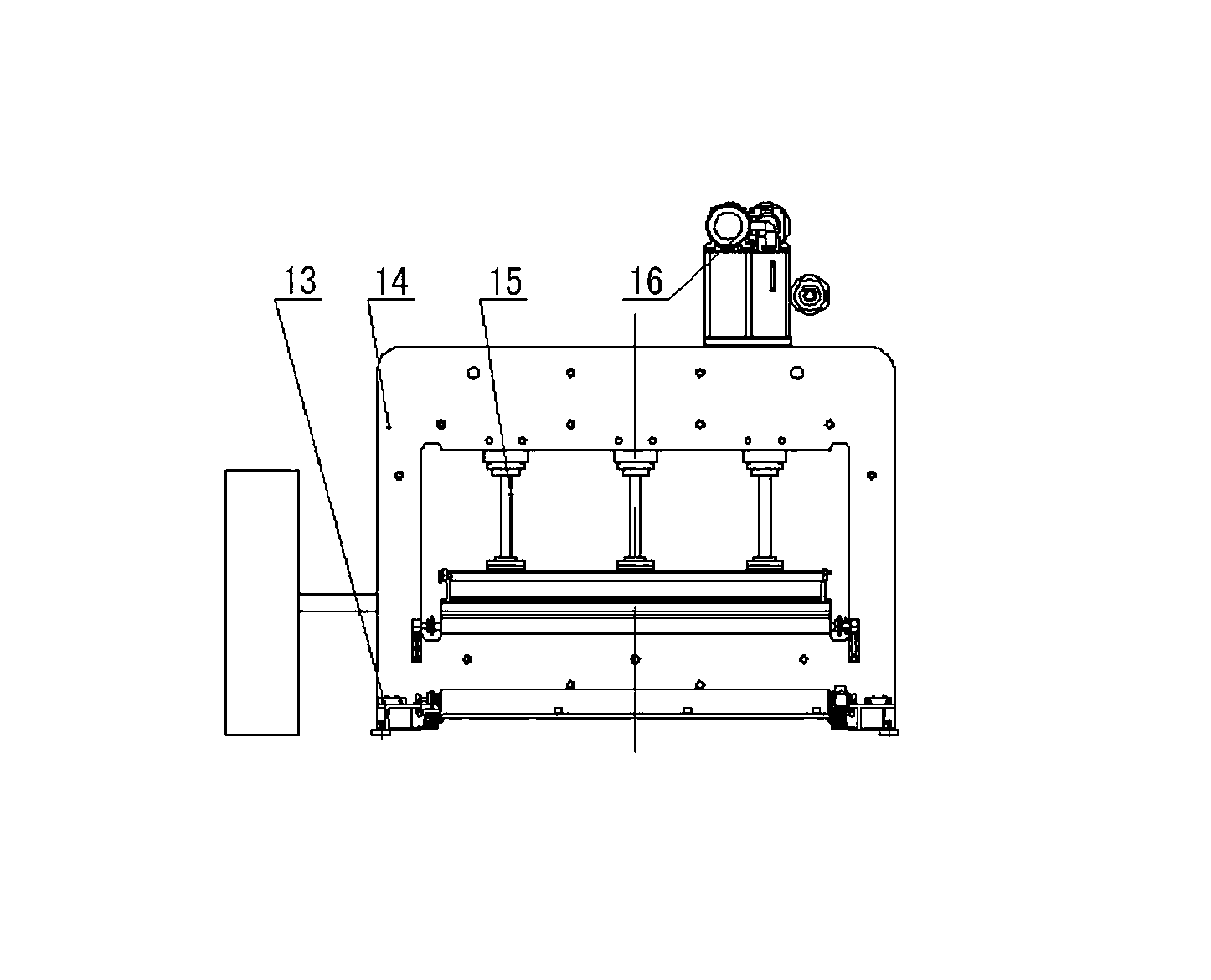

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as Figure 1 to Figure 4 The shown BIPV solar module positive pressure packaging equipment includes a base 13 arranged on the ground, and a metal structure gantry main frame composed of a plurality of gantry frames 14 installed on the base 13 . The plurality of gantry frames 14 are connected with through connecting positioning rods 6 to form a solid body through bolts (not marked in the figure), so as to avoid deformation caused by welding. This embodiment also includes a conveying device 10 passing through the gantry 14 . A lower heating plate 9 is arranged at the bottom of the gantry frame 14, corresponding to the upper heating plate 8 placed above the lower heating plate 9, and an upper box 7 is arranged on the upper heating plate 8, and the upper box 7 The lower surface is firmly connected with the upper surface of the upper heating plate 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com