Hot oil type tubular heater

A heater and tubular technology, applied in the field of tubular heaters, can solve the problems of communication, instrumentation and electronic equipment interference, not suitable for epoxy-based pultrusion mandrels, and endangering the health of employees, etc., to achieve stable thermal curing quality and social benefits Significant, low-cost production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

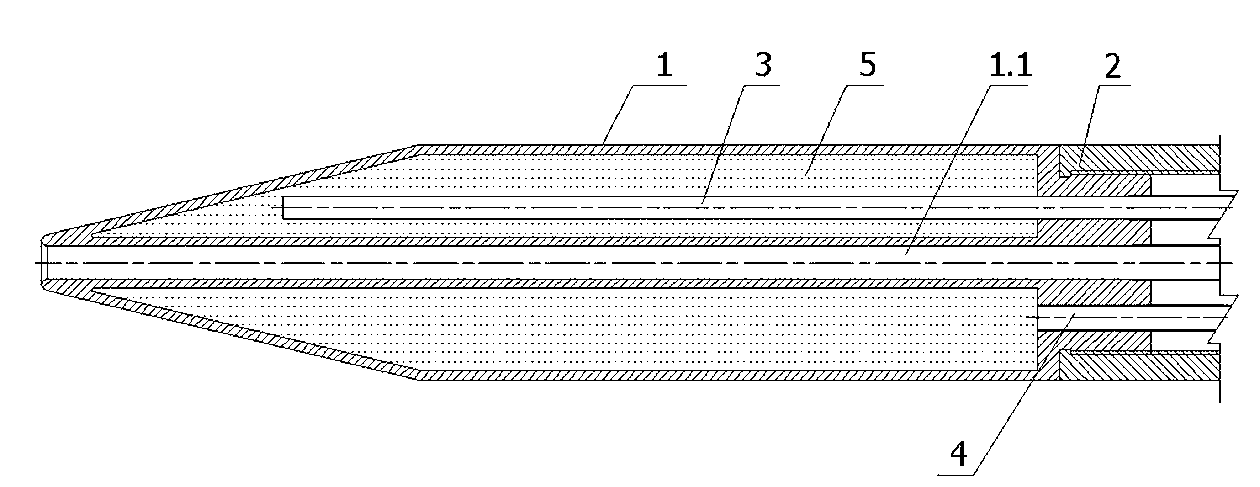

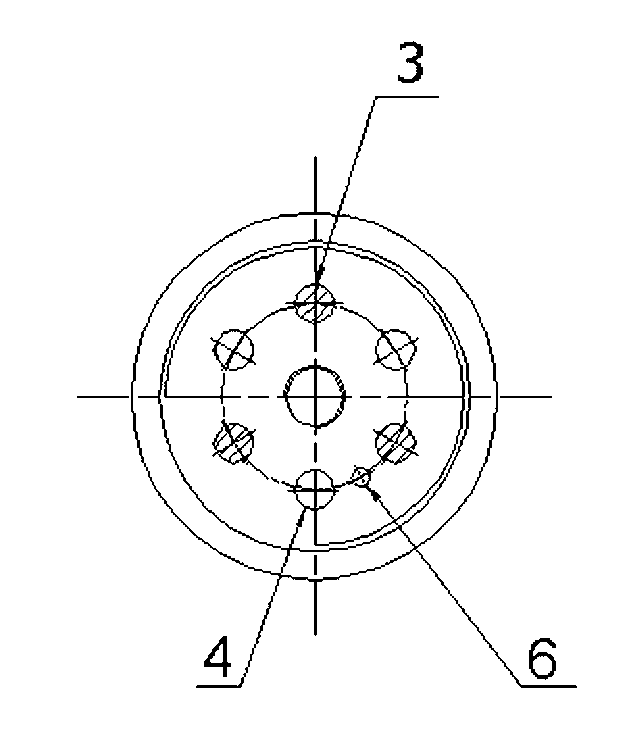

[0016] figure 1 The shown thermal oil tubular heater is used for the production of epoxy-based pultrusion mandrel, which includes a shell 1, a pipe joint 2, an inlet pipe 3, a return pipe 4, a heat medium 5 and a sensor 6. The shell 1 is a member of a jacketed tube structure, the built-in axial inner tube 1.1 is centered, the main body of the outer tube wall is composed of a truncated cone and a cylinder, and the inner tube 1.1 at one end is a truncated cone The small end of the body, and the bundle segment of the cylinder at the other end is provided with threads to cooperate with the pipe joint 2 to form a positioning installation, and the inner tube 1.1 of the bundle segment end face ring of the outer tube wall of the tube shell 1 is alternately sealed and connected with 3 lead-in tubes 3 at equal intervals And 3 return pipes 4. The heat medium 5 is heat-conducting oil, and the heat medium 5 carries temperature to heat the shell 1. The inlet pipe 3 and the return pipe 4 th...

Embodiment 2

[0018] This embodiment is used for the manufacture of epoxy-based pultrusion mandrels of φ170mm. Because the product specification is larger than that of embodiment 1, the amount of rubber and alkali-free glass fiber consumed is more. The structure is the same as that of Embodiment 1, but the main technical parameters have been adjusted. For example, the diameter of the axial inner tube 1.1 built in the shell 1 is increased to φ28mm, the taper of the truncated cone is 1:5, and 6 inlet tubes 3 and 6 are configured. A return pipe 4, the thermal oil tubular heater under this configuration is similar to the application effect of embodiment 1, and the energy consumption is only 1 / 30 of the prior art.

[0019] The application of the invention has good economic and social benefits.

Embodiment 3

[0021] This embodiment is used for the manufacture of epoxy-based pultrusion mandrels with a diameter of φ200mm. Because the product specification is larger than that of Embodiment 1, the consumption of rubber and alkali-free glass fibers is more, although the thermal oil tubular heater used The structure is the same as that of Embodiment 1, but the main technical parameters have been adjusted. For example, the diameter of the axial inner tube 1.1 built in the shell 1 is increased to φ50mm, the taper of the truncated cone is 1:6, and 8 guide tubes 3 and 8 are configured. Root return pipe 4, the thermal oil type tubular heater under this configuration is similar to the application effect of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com