Deep hole punching method and deep hole punch head thereof for large forging

A technology of large forgings and deep holes, applied in the field of forging, can solve the problems of complex machining process, long production cycle, stress concentration, etc., to eliminate internal structure defects, homogenize internal structure, and reduce stamping force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

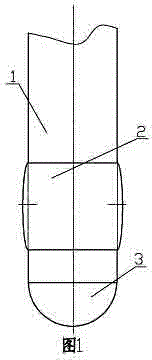

Image

Examples

Embodiment Construction

[0030] Taking a straight-through pipe section of an ultra-supercritical generator set as an example, the finished straight-through pipe section has an outer diameter of 566mm, a length of 3200mm, an aperture of 302mm, a pipe wall thickness of 132mm, and an aspect ratio of the pipe hole of 10.6. The octagonal prism-shaped forged steel ingot is adopted, and the material of the ingot is martensitic heat-resistant steel P112.

[0031]Firstly, the steel ingot is heated in stages to raise the temperature. First, the forged steel ingot is put into the heating furnace for heating to improve the plasticity of the metal, make it easy to flow and form and obtain a good forged structure. Selecting the appropriate heating temperature range can make the metal blank in the furnace. Forming in a state of good plasticity. Since the steel ingot is a large piece, in order to reduce the temperature stress caused by the temperature difference of the section, the steel ingot should be heated evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com