Hot pressing device for flexible solar battery component

A technology for solar cells and hot pressing devices, applied in lamination devices, electrical components, lamination and other directions, can solve the problems of affecting product appearance, unstable quality, slow heating speed, etc., to ensure product quality and appearance, heating temperature The effect of the same time and slow heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

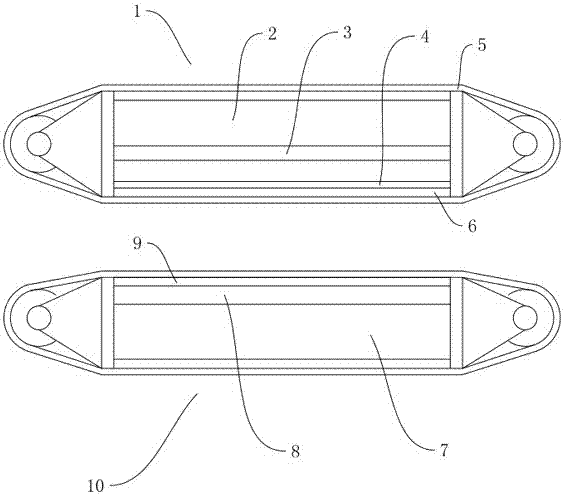

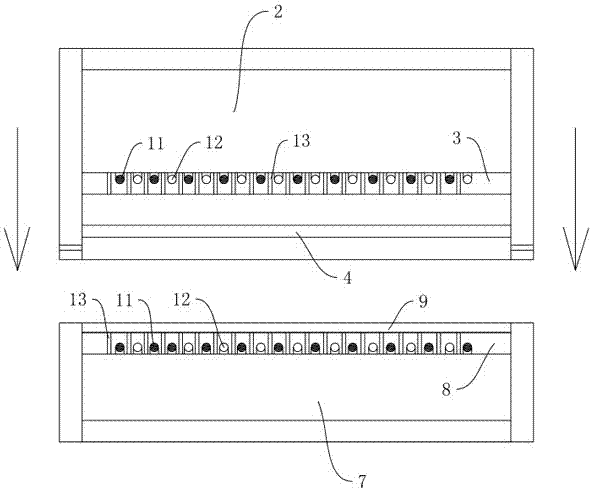

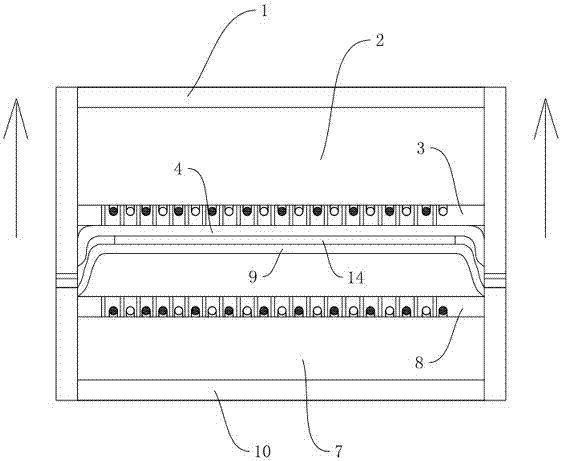

[0029] Embodiment: A kind of flexible solar cell assembly thermocompression device (referring to figure 1 figure 2 image 3 ), including: an upper part 1 and a lower part 10 that can be stacked to form a closed hot-press chamber; a heating system for heating the hot-press chamber; a vacuum pump for vacuuming the upper part and the lower part system; a control system for controlling the heating system and the vacuum system; and a conveying device for feeding components into and out of the autoclave.

[0030]An upper partition 3 is arranged in the middle of the upper part, and the upper partition divides the upper part into a closed upper heating chamber 2 and an upper part of the hot-press chamber 6, and the lower part is provided with a lower partition 8, which separates the lower part into a closed The lower heating chamber 7 and the lower part of the thermocompression chamber. The upper part is provided with an upper silica gel plate 4 on the upper part of the hot-pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com