A Whole Ultrasonic Heating Method for Variable Cross-section Rods

A heating method and variable cross-section technology, applied in vehicle parts, transportation and packaging, etc., can solve complex and difficult to operate, easy to deform heating equipment, uneven heating of stabilizer bars, etc., to avoid fatigue failure, low deformation, prevent The effect of high temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

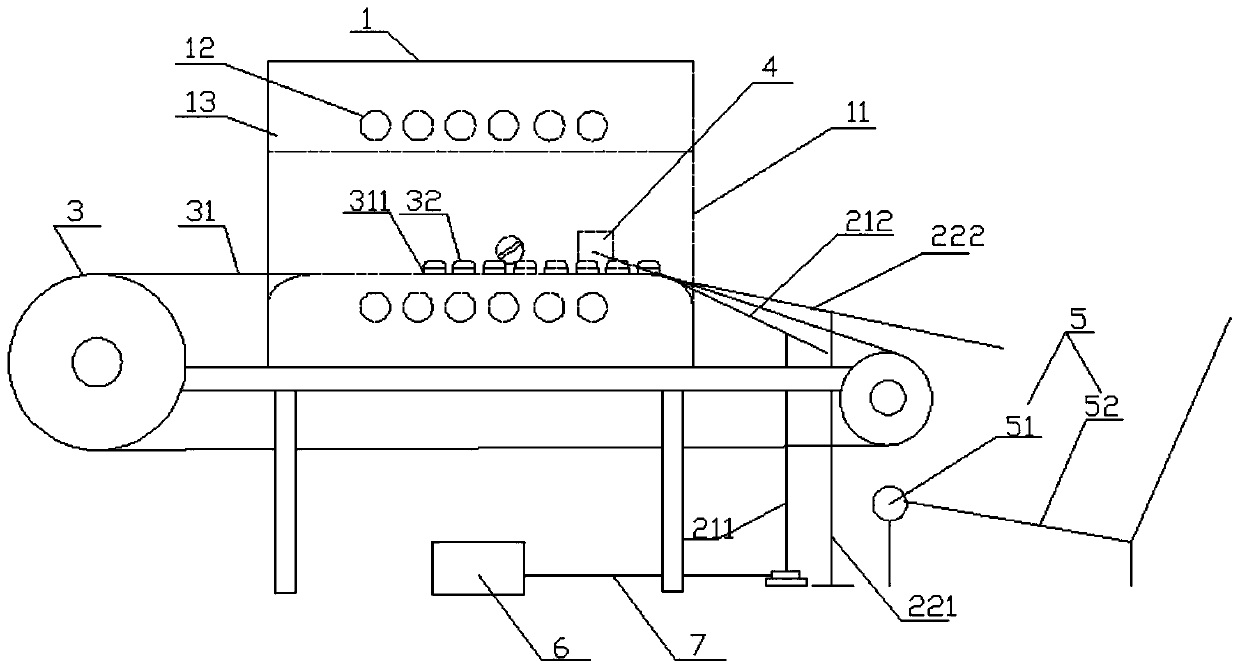

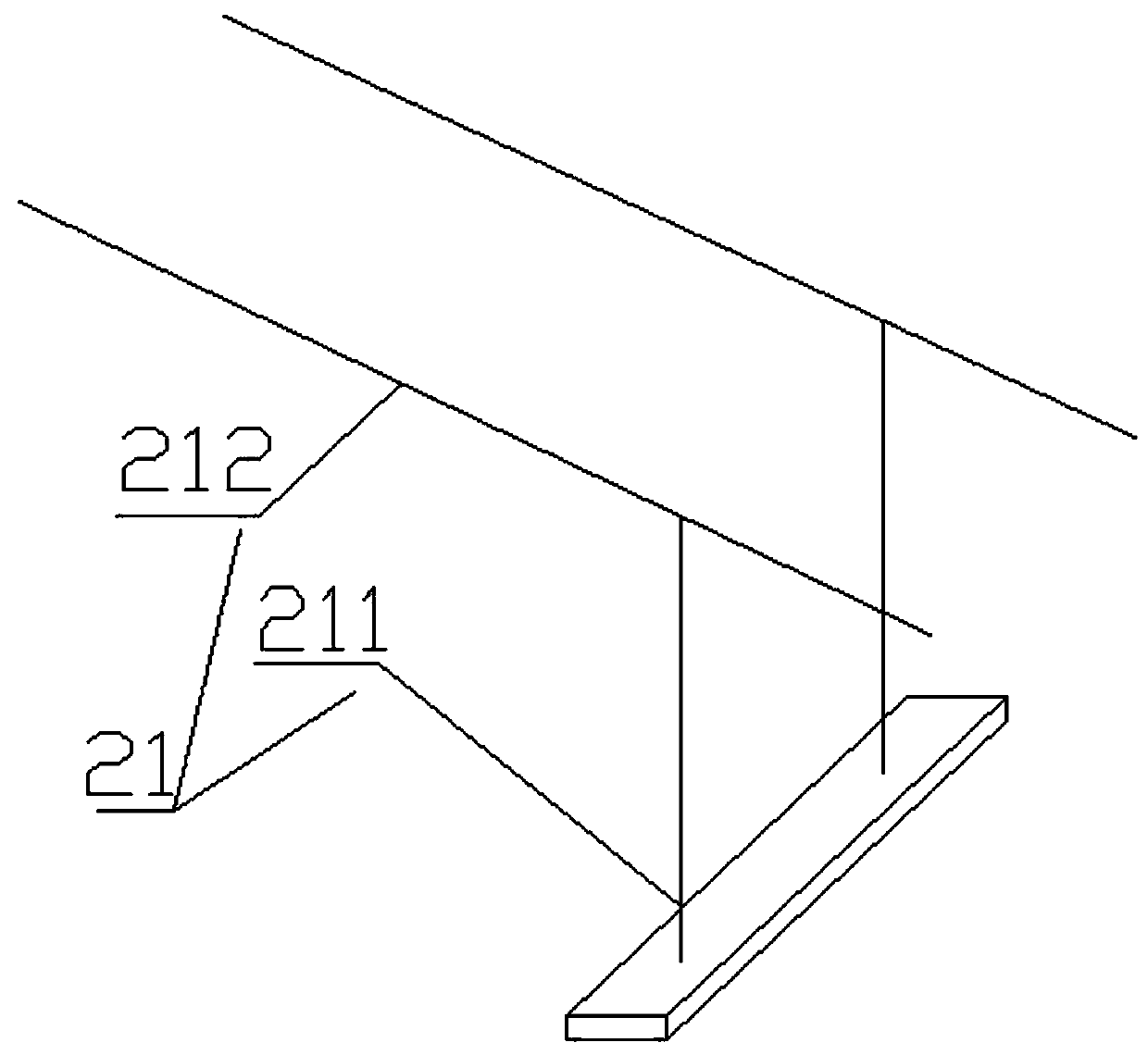

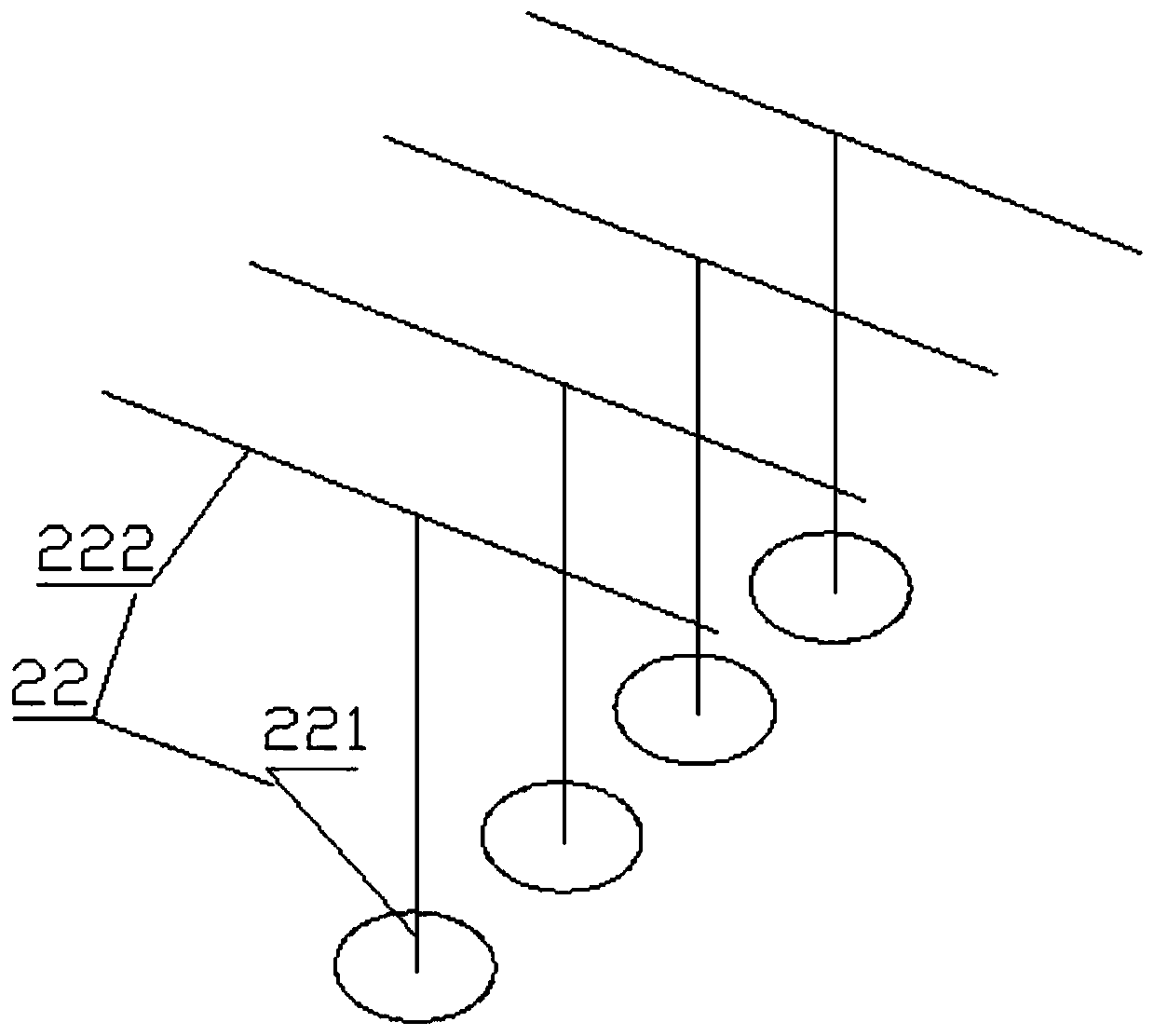

[0033] Embodiment one, such as figure 1 , figure 2 , image 3 The overall supersonic heating equipment with variable cross-section rods shown includes two sets of shift forks 21 and four sets of conveying mechanisms 22, and the brackets 1 212 of the two sets of shift forks 21 are arranged on the same base.

[0034] In specific work, several workpieces to be heated are successively sent to the heater of the overall supersonic heating equipment for variable-section rods by the conveyor belt 31, and the limiting member 4 concentrates and restricts the workpieces to be heated in the heating area of the heater 1. After the workpiece is heated, the motor 6 is started. The motor 6 drives the shift fork 21 to move in an arc towards the direction of the discharge port 11 . During the movement, the support one 211 gradually rises and leans against the discharge port 11. Since the driving rod 212 is movably connected with the support one 211, the driving rod 212 is driven by the su...

Embodiment 2

[0037] In the second embodiment, the receiving device 5, the shift fork 21 and the conveying device 22 can be independent of each other, and can also be fixed on the frame of the overall supersonic frequency heating equipment of variable cross-section rods as required. Of course, according to the frame structure of the overall super-audio frequency heating equipment of different variable cross-section rods, in order to better play their respective functions for the material receiving device 5, the shift fork 21 and the conveying device 22, the material receiving device 5, the shift fork 21 and the support structure of conveying device 22 are slightly deformed to adapt to the frame of heating equipment, as Image 6 shown.

[0038] In the second embodiment, on the rack of the overall supersonic heating equipment for variable-section rods, a conveying mechanism 22 , two sets of shift forks 21 , and a material receiving device 5 are sequentially arranged outward from the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com