Supersonic-frequency heating method for uniformly heating overall variable-section rod part

A technology of uniform heating and heating method, which is applied in the field of super-audio frequency heating, can solve the problems of complicated and difficult operation of heating equipment, uneven heating of stabilizer rods, etc., and achieve the effects of avoiding fatigue failure, same hardness, and consistent heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

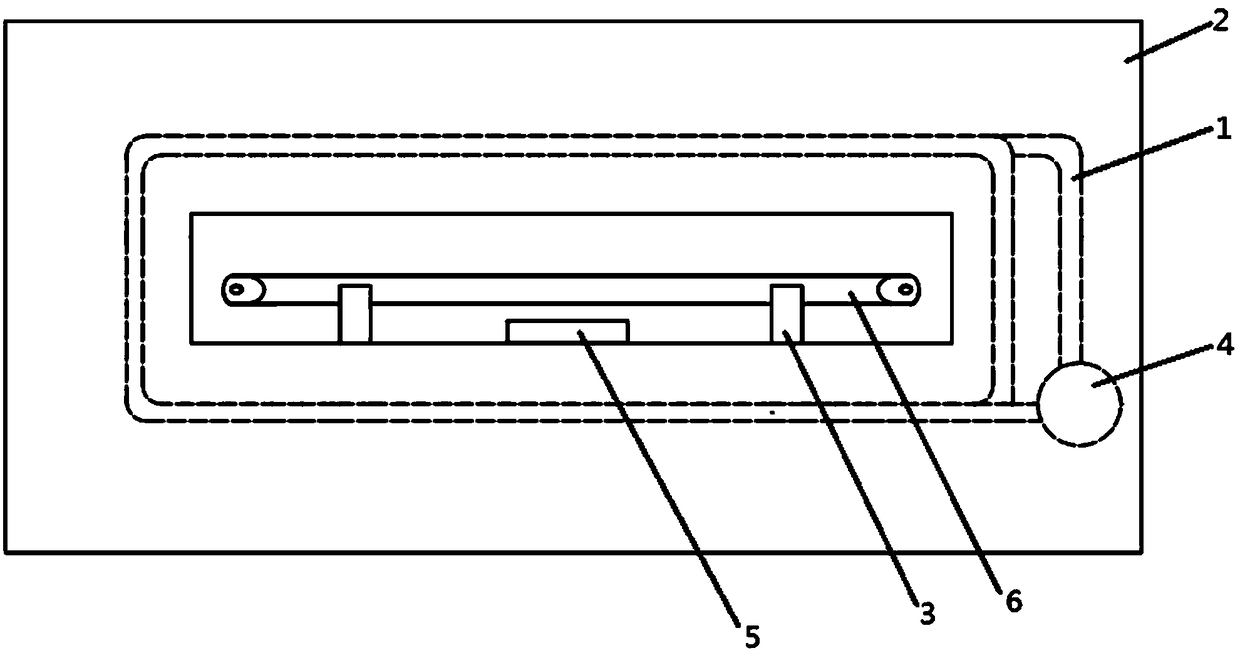

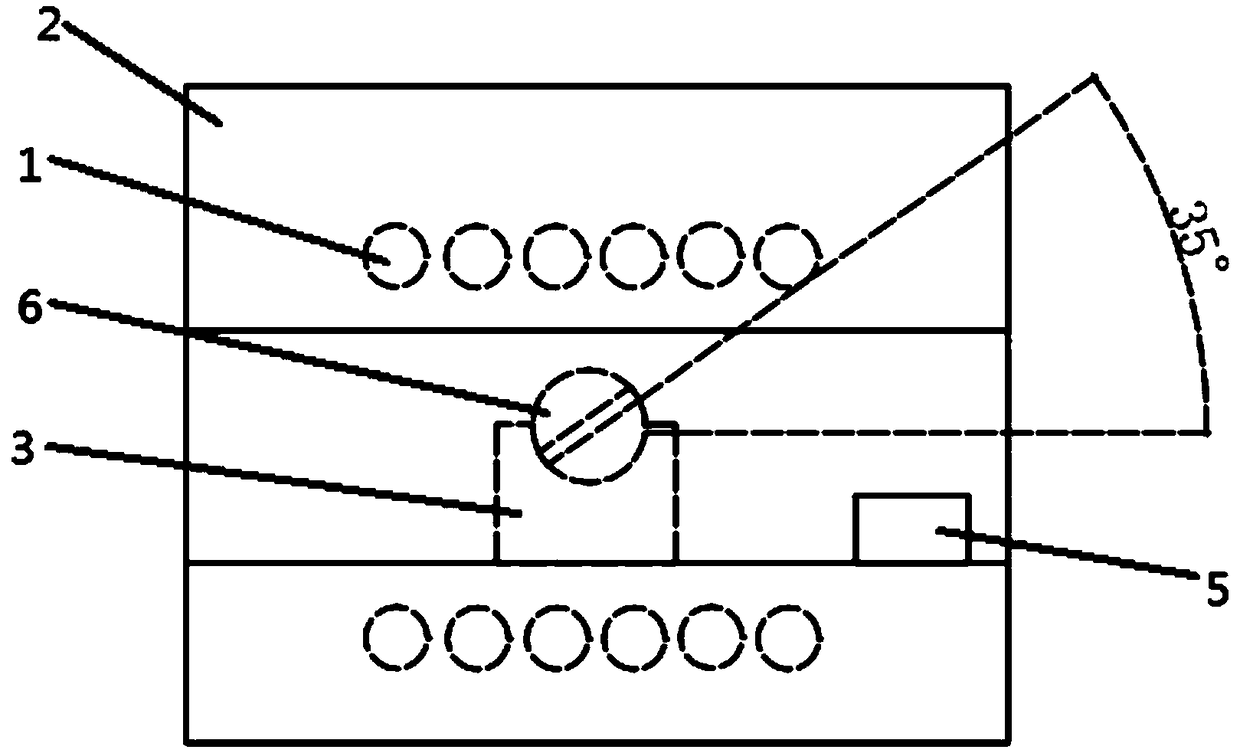

[0022] Embodiment one, such as figure 1 , figure 2 As shown, the present invention provides an overall supersonic heating method for variable-section rods, which is applied to an overall supersonic heating device for variable-section rods. Direction Horizontally set at least two or more positioning parts 3 for placing rods with variable cross-sections, a super-audio heating power supply 4 and a temperature detector 5. The heating coil 1 is inside an insulating casing 2 . The insulating shell 2 is provided with a through hole along the opening axis direction of the heating coil 1 . The through hole is located in the cavity of the heating coil 1 . The positioning piece 3 is located in the through hole and surrounded by the heating coil 1 , and a groove is provided in the middle of the upper end surface of the positioning piece 3 . The axis of the groove is perpendicular to the opening axis of the heating coil 1. The rod body of the variable-section rod 6 is placed in the gr...

Embodiment 2

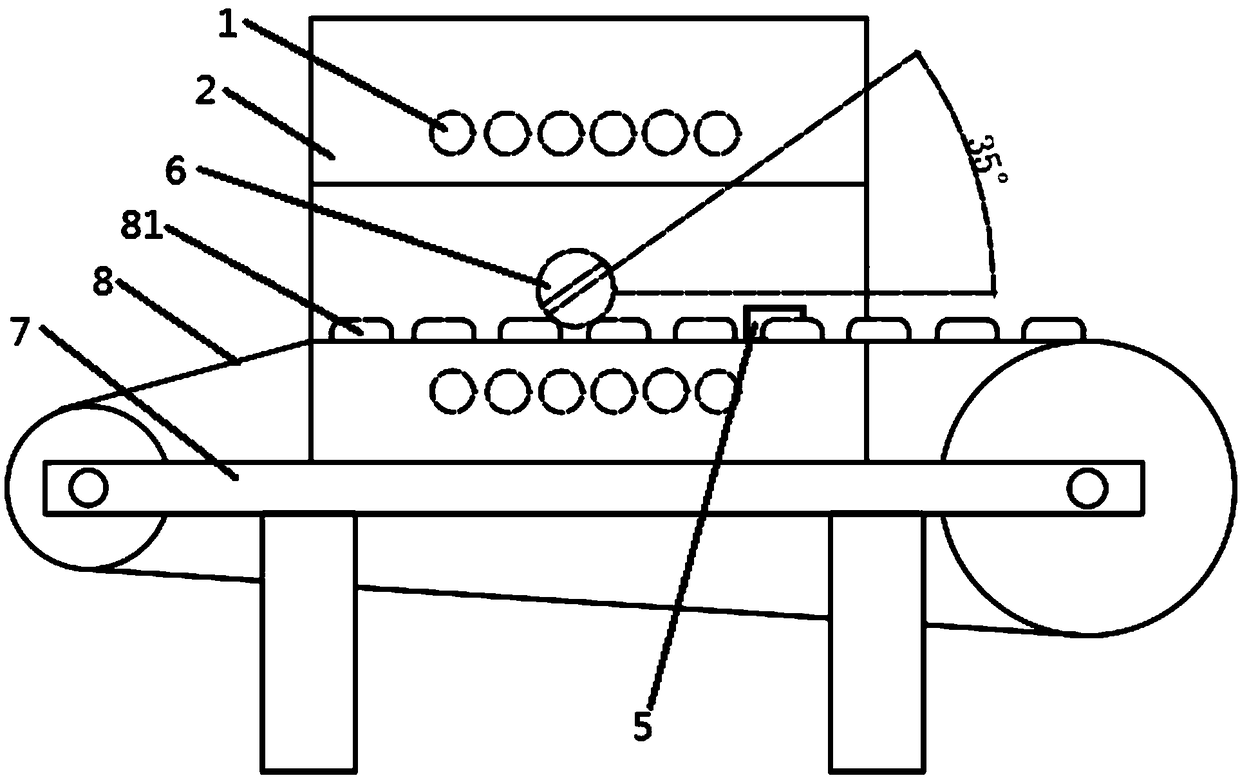

[0032] Embodiment two, such as image 3 As shown, in actual work, the crawler conveyor belt 8 can also be used instead of the positioning member 3 . Crawler conveyor belt 8 is fixed on the frame 7. During work, the variable section rod 6 is placed between two adjacent track shoes 81, the rod body of the variable section rod 6 is limited by using the gap between the adjacent track shoes 81, and the variable section of the variable section rod 6 is adjusted. The included angle with the opening axis of the heating coil 1 is within the range of 30°-40°. Afterwards, the crawler conveyor belt 8 is started to send the variable-section rod 6 into the supersonic heating equipment, and the heating coil 1 is started to heat the variable-section rod 6 . The probe of the temperature detector 5 detects the temperature of the variable section rod 6 . When the temperature reaches the set value, the temperature detector 5 sends an alarm signal, and the power supply can be disconnected, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com