Automatic candy supply system of cotton candy machine

A cotton candy, automatic technology, applied in confectionery, confectionery industry, food science and other directions, can solve the problems of inconvenient to guide the direction and speed of the candy silk, affecting the shape design of the marshmallow, and difficult to control the humidity of the candy, etc. To achieve the effect of increasing artistry and appreciation, facilitating production and maintenance, and facilitating the disassembly of utensils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

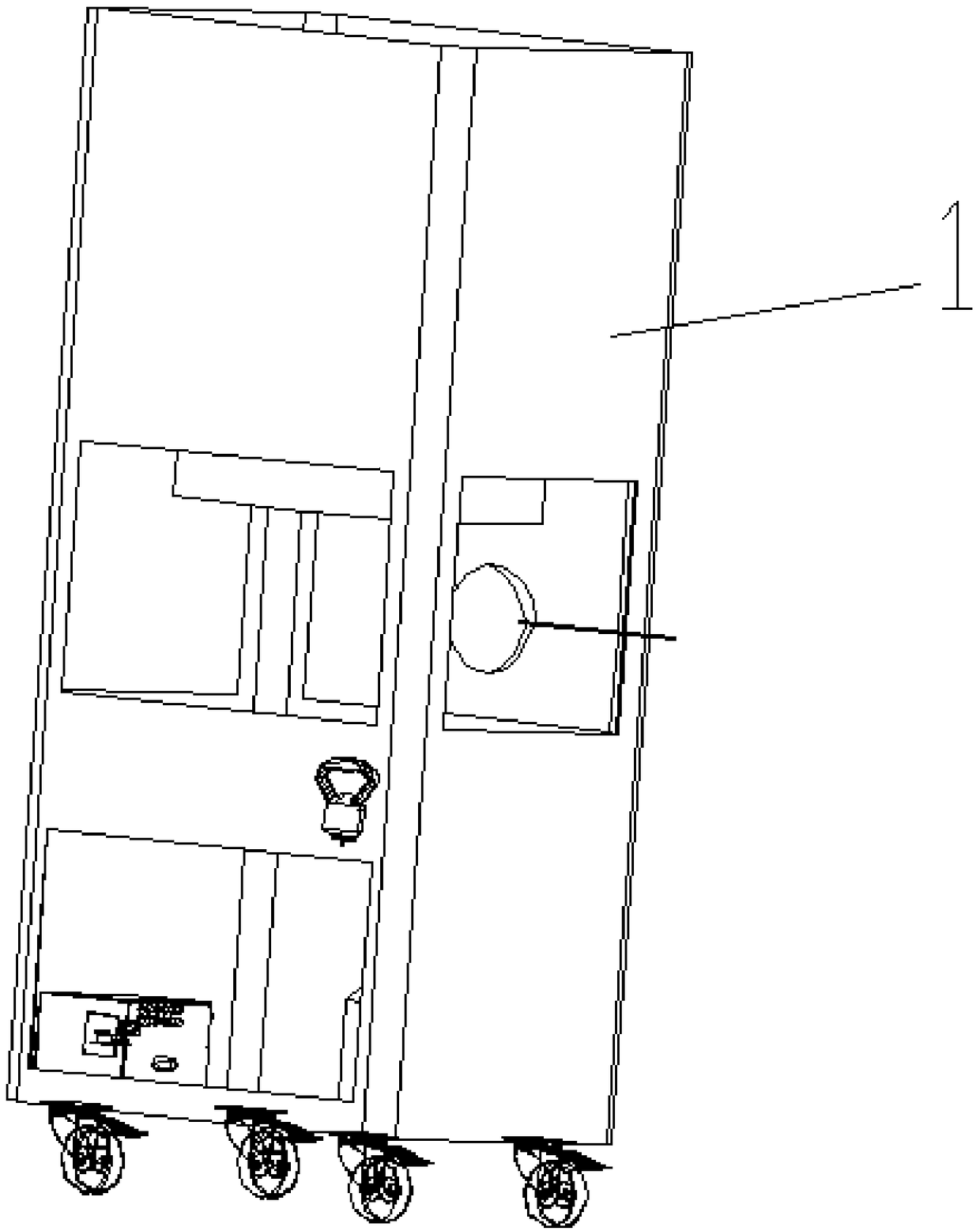

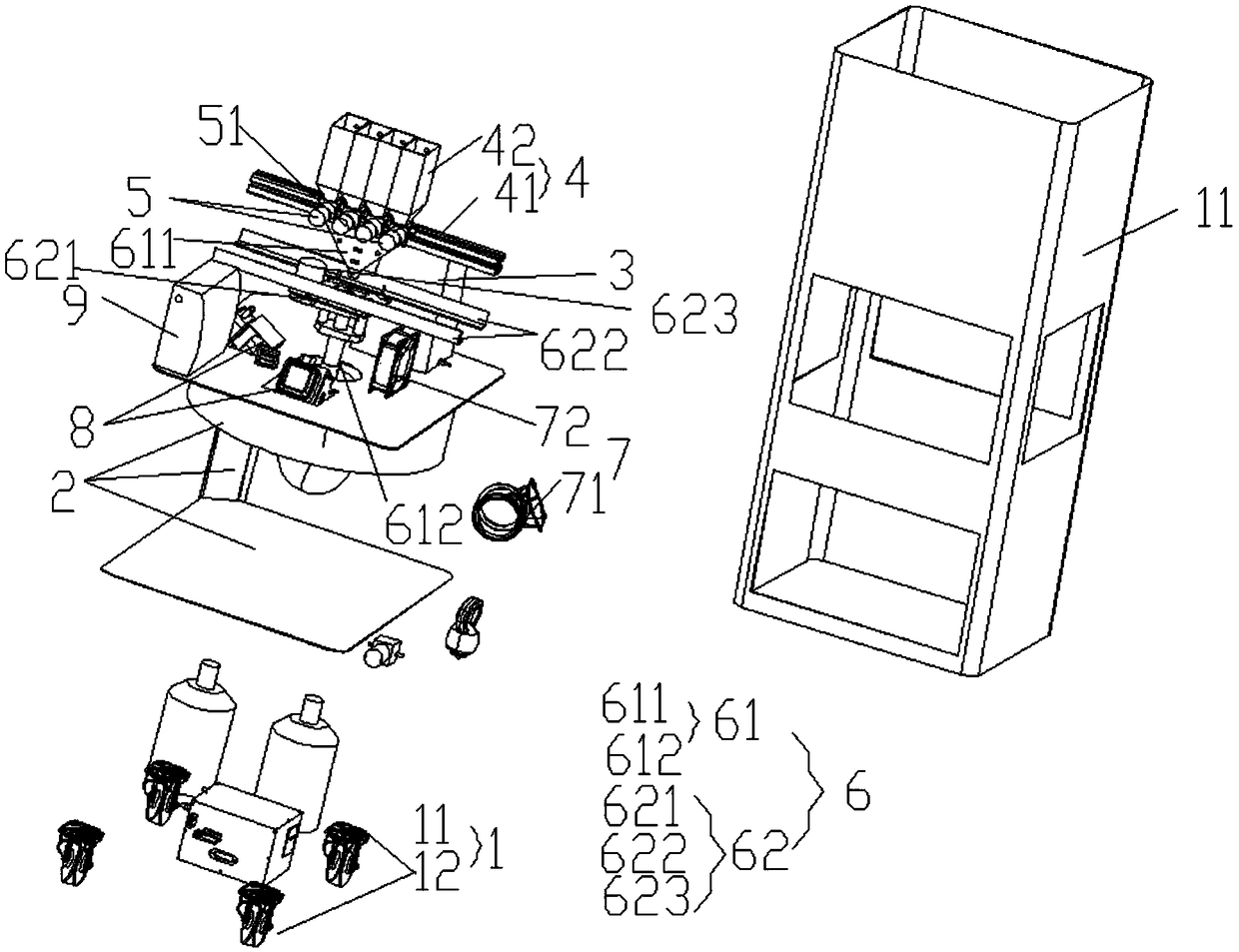

[0024] Please refer to Figure 1 to Figure 2 , an automatic sugar supply system for a cotton candy machine of the present invention, comprising: a fixed frame mechanism 1, a support frame mechanism 2, a humidifier 3, a sugar box module 4, a sugar amount control mechanism 5, a sugar dispenser control mechanism 6, Fan mechanism 7, microwave transmitter module 8 and control electric box 9, wherein, the support frame mechanism 2 is arranged in the described fixed frame mechanism 1, and the humidifier 3 is arranged on the described support frame mechanism 2, so The sugar box module 4 is arranged on the support frame mechanism 2, the sugar amount control mechanism 5 is arranged on one side of the sugar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com