Fully-automatic continuous heating furnace for bars

A heating furnace, fully automatic technology, applied in the direction of lighting and heating equipment, furnace, crucible furnace, etc., can solve the problems that the bars cannot be first in first out, the temperature of forging materials is difficult to control, and the degree of automation is low, so as to reduce the labor intensity of workers , the same heating time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, invention will be further described:

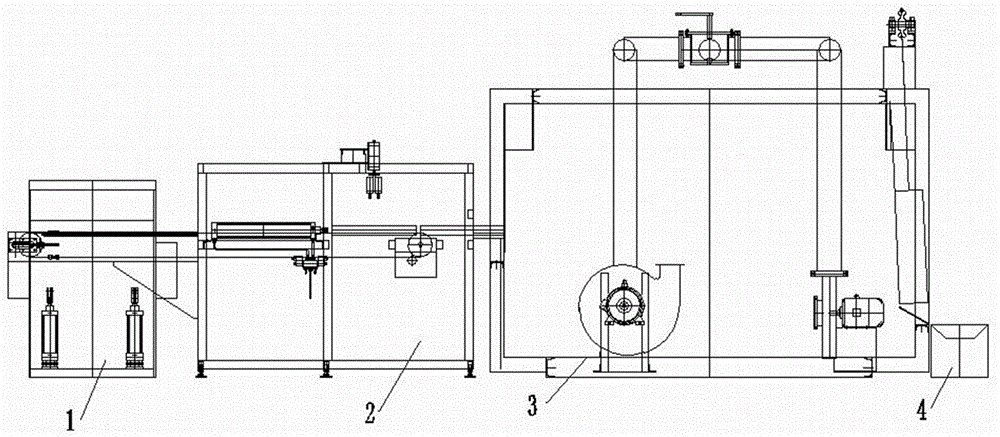

[0021] Such as figure 1 As shown, the present invention includes a material storage and feeding machine, a material pushing machine, a natural gas heating furnace, and a red material conveyor from front to back according to the order of arrangement.

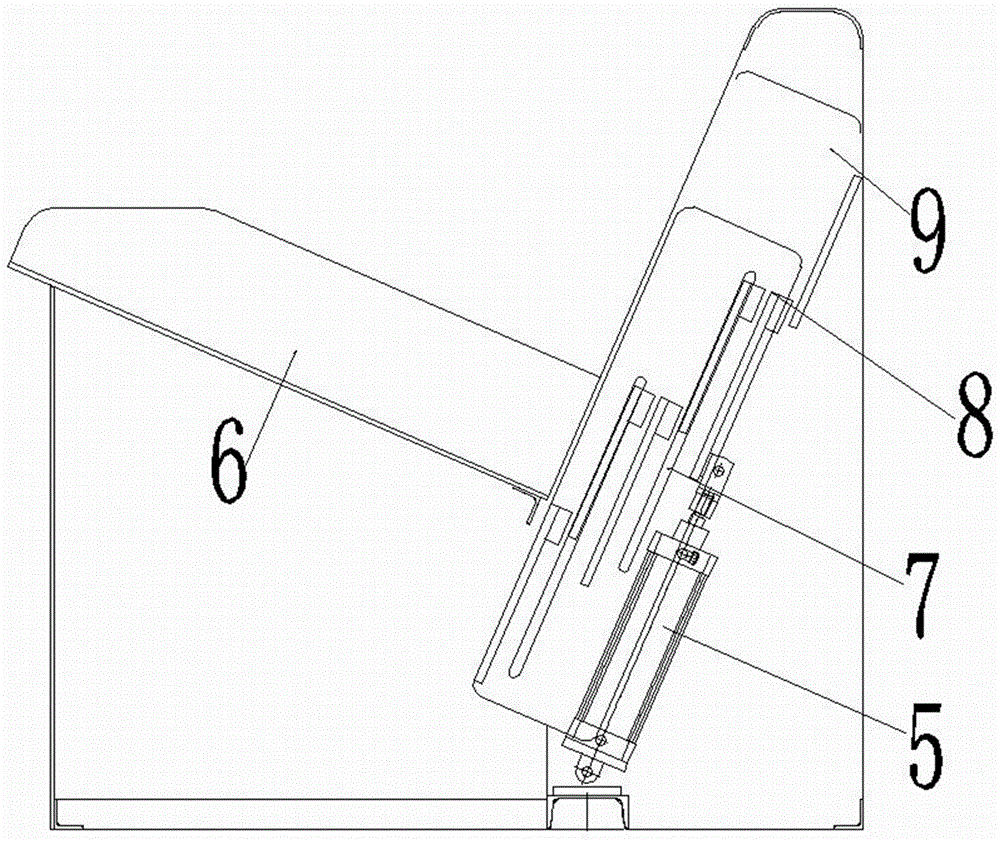

[0022] Such as figure 2 As shown, the storage and feeding machine includes two cylinders, a storage bin, a dynamic push plate, a static push plate, and a frame. Two cylinders are fixed on the frame, and a magnetic travel switch is arranged inside the cylinder. The cylinder pushes the moving push plate according to the set stroke and frequency, and pushes the bar in the silo to the static push plate. After reciprocating motion, the bar is gradually pushed to the chain conveyor of the cloth pusher.

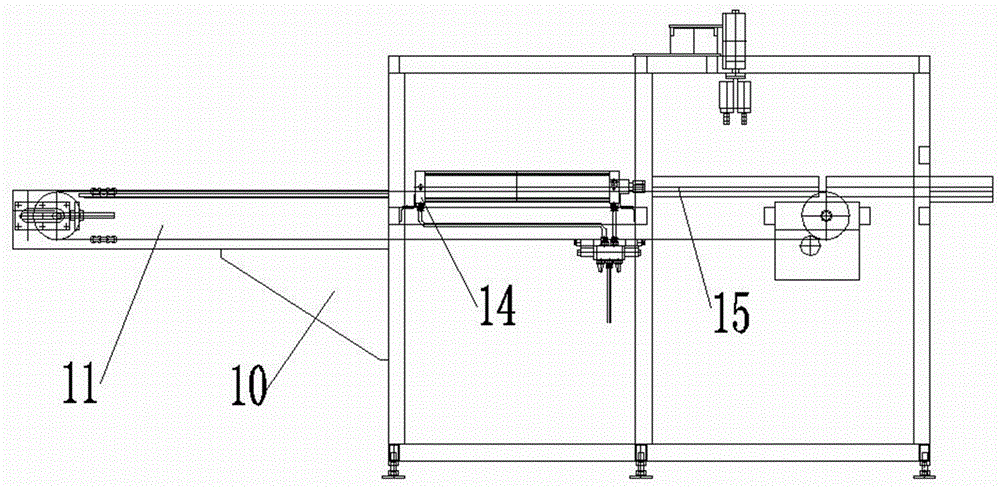

[0023] Such as Figure 3-4 As shown, the cloth pushing machine includes a chain conveyor, a frame, two pushing cylinders, six slide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com