Enrichment separation method of hydrogen isotopes through displacement chromatography

A technology of replacement chromatography and hydrogen isotope, applied in the field of hydrogen isotope separation, can solve the problems of difficulty in separation and enrichment of deuterium and tritium, achieve better separation effect and overcome the effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

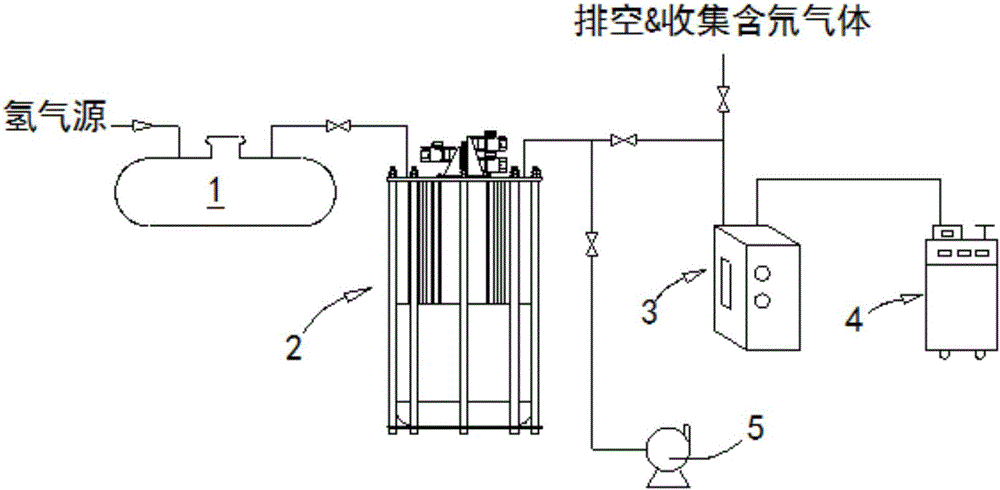

Image

Examples

Embodiment 1

[0045] Prepare the molecular sieve column:

[0046] When preparing the molecular sieve column, select a stainless steel tube with an inner diameter of 12mm as the main structure of the molecular sieve column. After mixing evenly with adhesive and 5A molecular sieve, fill it into the above-mentioned stainless steel tube. After the filling is full, use a tube bending machine to bend the stainless steel tube into a spiral coil structure. The diameter of the spiral coil is the size that can be put into the liquid nitrogen tank. , the molecular sieve column required for the experiment was obtained.

[0047] Compared with the general molecular sieve column filling method, the spiral coil structure of the present invention significantly saves the volume of the molecular sieve column, and can more conveniently use liquid nitrogen to cool it down.

[0048] Displacement chromatography tritium enrichment separation:

[0049] Immerse the molecular sieve column completely in liquid n...

Embodiment 2

[0052] X molecular sieve material, the effect of different lifting speeds on the separation of hydrogen isotopes

[0053] Prepare X-type molecular sieve, add adhesive, extrude into strips, and fill in the molecular sieve column. The molecular sieve column is completely immersed in liquid nitrogen, and the liquid nitrogen completely submerges the molecular sieve column, so that the temperature of the molecular sieve column is reduced to the temperature of liquid nitrogen. Inject natural hydrogen gas (deuterium containing natural abundance) into the constant volume container, after the pressure of the constant volume container reaches an atmospheric pressure and stabilizes, close the injection valve, then open the valve between the constant volume container and the molecular sieve column to allow the natural hydrogen to flow into the molecular sieve column, and after the air pressure stabilizes, close the valve so that the hydrogen can be fully adsorbed on the adsorption colum...

Embodiment 3

[0060] Analyze the influence of the inner diameter of stainless steel pipes of different sizes on the separation efficiency

[0061] Prepare a type A molecular sieve, and fill it in a 316 stainless steel pipe with an inner diameter of 12 mm to make a molecular sieve column. Immerse the molecular sieve column completely in liquid nitrogen to reduce the temperature of the molecular sieve column to the temperature of liquid nitrogen. Replace and evacuate the gas in the molecular sieve with hydrogen, then treat the gas in the molecular sieve column, and then vacuumize it to keep the vacuum in the molecular sieve column. Inject natural hydrogen gas (deuterium containing natural abundance) into the constant volume container, after the pressure of the constant volume container reaches an atmospheric pressure and stabilizes, close the injection valve, then open the valve between the constant volume container and the molecular sieve column to allow the natural hydrogen to flow into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com