Mold baking heating method, heating process method and heating furnace production device

A production device and heating device technology, applied in the heating field, can solve the problems of high local mold temperature, uneven heating, long heating time, etc., and achieve the effect of meeting the production process requirements, basically consistent heating temperature, and avoiding uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

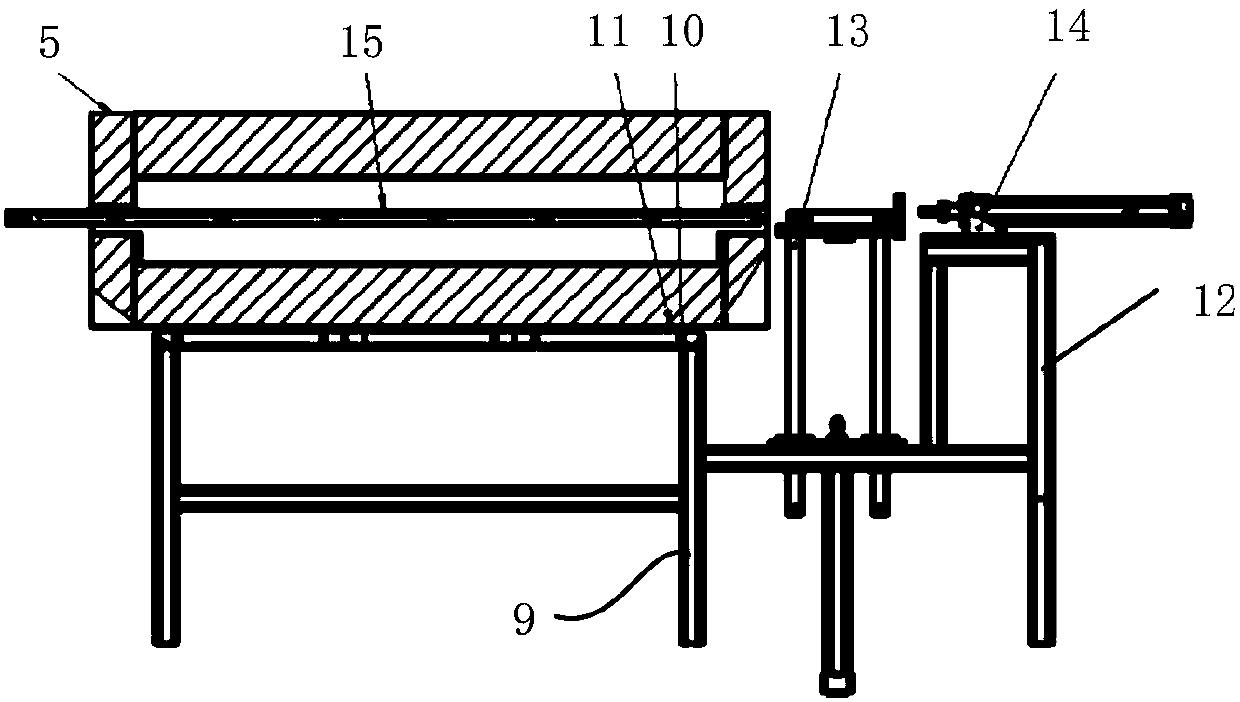

[0060] Preferred implementation mode: the casting and welding bottom mold 15 is transferred to the jacking mechanism 13, the casting and welding bottom mold 15 is lifted to the entrance of the box body 5, and the propulsion mechanism 14 pushes the casting and welding bottom mold 15 into the heating space. A casting and welding bottom mold 15, after the new casting and welding bottom mold 15 enters the heating space, the cast and welding bottom mold 15 that has been heated closest to the exit is extruded from the exit, and the cast and welding bottom mold 15 that is extruded is moved to The next station completes the next process.

[0061] The present invention also provides a mold baking heating method, using the above-mentioned heating furnace production device to heat the object to be heated, including the following steps: Step S1: adjust the temperature in the box body 5 through a temperature controller; Step S2: The jacking mechanism 13 sends the recovered object to be hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com