Explosion-proof electric heater

A technology of electric heaters and electric heating elements, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as failure to meet explosion-proof requirements, unstable heating temperature, corrosion of explosion-proof sealing surfaces, etc. Fast speed, good heating effect, and the effect of ensuring long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

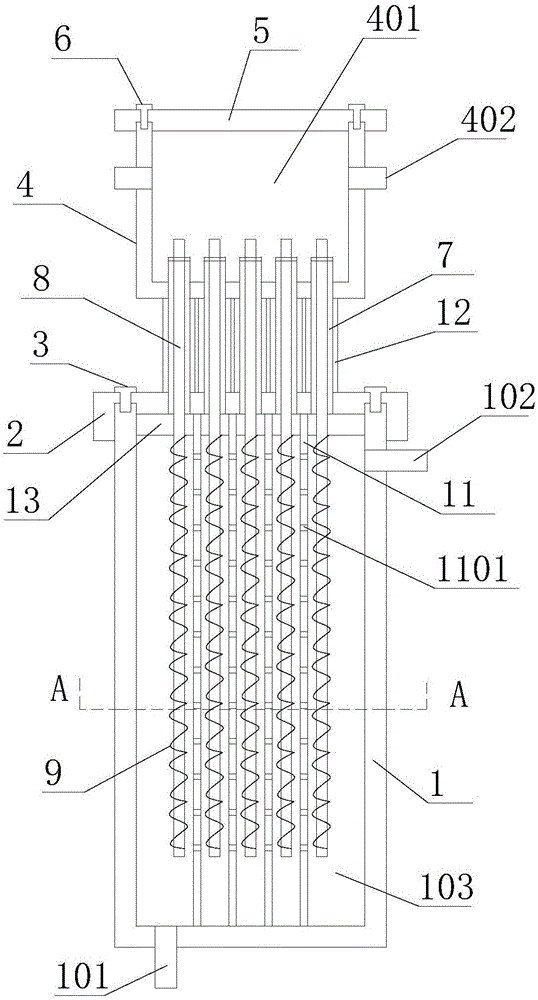

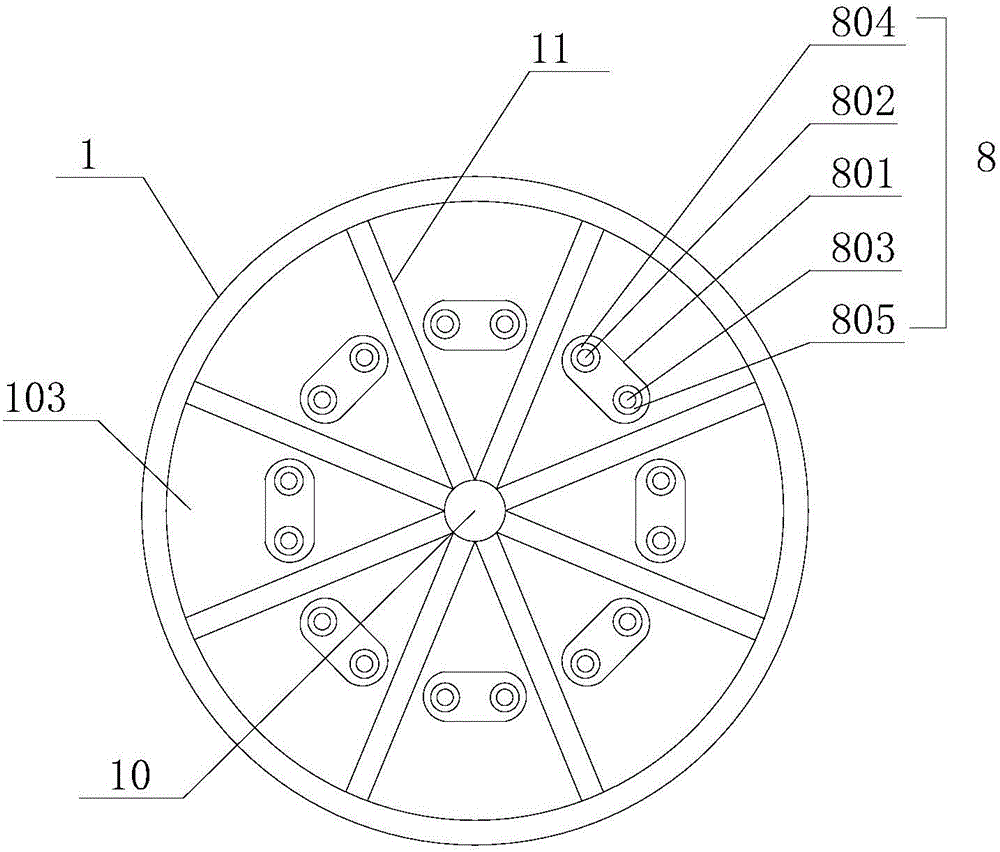

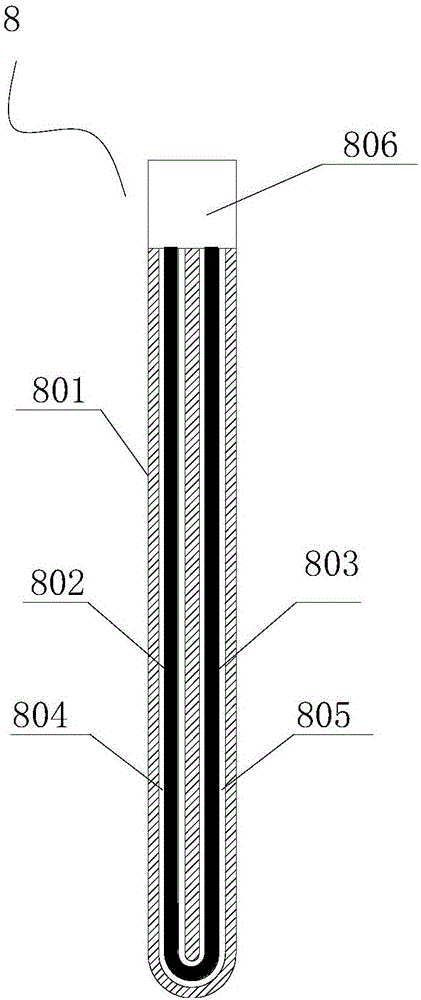

[0020] refer to figure 1 , figure 2 , image 3 , the present invention proposes an explosion-proof electric heater, including a container body 1, a container cover 2, a plurality of first connectors 3, an explosion-proof junction box 4, an explosion-proof cover 5, a plurality of second connectors 6, and a plurality of sleeves 7 , a plurality of electric heating elements 8, wherein:

[0021] The container body 1 is a cylinder structure with one end open. A heating chamber is arranged inside the container body 1. The container body 1 is provided with a medium inlet 101 and a medium outlet 102 connected with the heating chamber. The outer side of the container body 1 is wrapped with a layer of insulation layer. The layer is made of glass fiber or asbestos material. The container cover 2 is installed on the open end of the container body 1, and is used to seal the heating chamber. The inner side of the container cover 2 is provided with a thermal insulation board 13, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com