Strain meter for plastic deformation test and manufacturing and calibration method thereof

A plastic deformation and strain gauge technology, applied in the field of strain gauges, can solve the problems of small strain measurement range, sensitive grid fracture and damage, etc., and achieve the effects of not easy fracture damage, good ductility and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

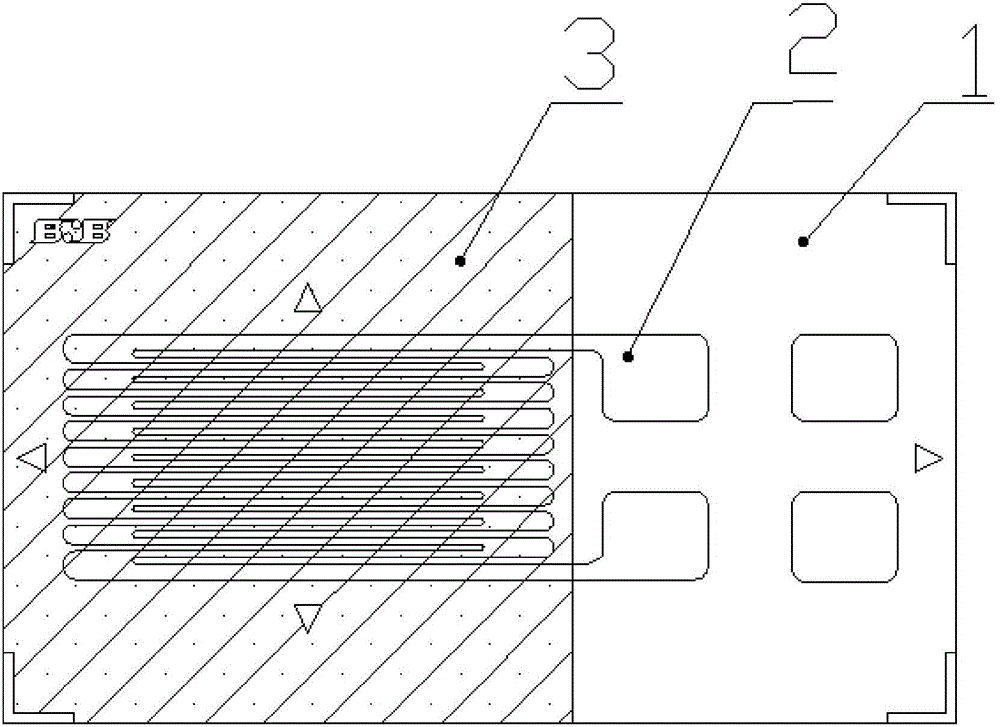

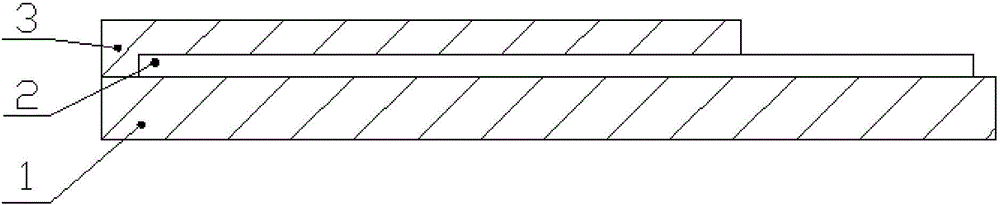

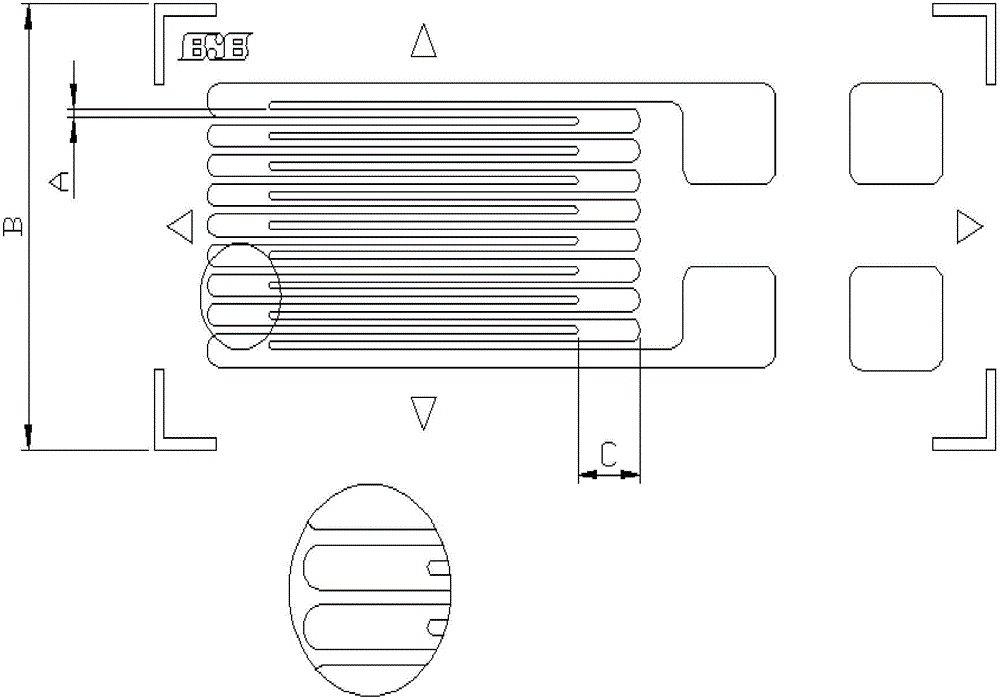

[0026] The present invention designs a strain gauge for plastic deformation testing by comprehensively considering the tolerance of the material of the sensitive grid, the base and the sealing layer and the structural size of the strain gauge on the deformation measurement range. Composed of substrate 1, sensitive grid 2, and sealing layer 3; the material of the sensitive grid matches well with the material of the base and the sealing layer; the structural size of the strain gauge is optimized to adapt to high plastic deformation tests; at the same time, it is calibrated by the mechanical tensile displacement method.

[0027] First of all, the material of the sensitive gate: the low-temperature heat treatment usually used, the common constantan and Karma alloy foils will cause fracture and damage when used for plastic deformation measurement, mainly because the ductility and elongation of these materials cannot reach the corresponding The indicators cannot meet the requirements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com